Plug Wrap or Tipping Paper for Smoking Articles

a technology of plug wraps and smoking articles, which is applied in the field of plug wraps for smoking articles, can solve the problems of not disclosing the use of such combined wrappers as plug wraps or tipping, and achieve the effects of reducing vapour phase constituents in smoke, improving filter efficiency, and increasing the reduction of vapour phase components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

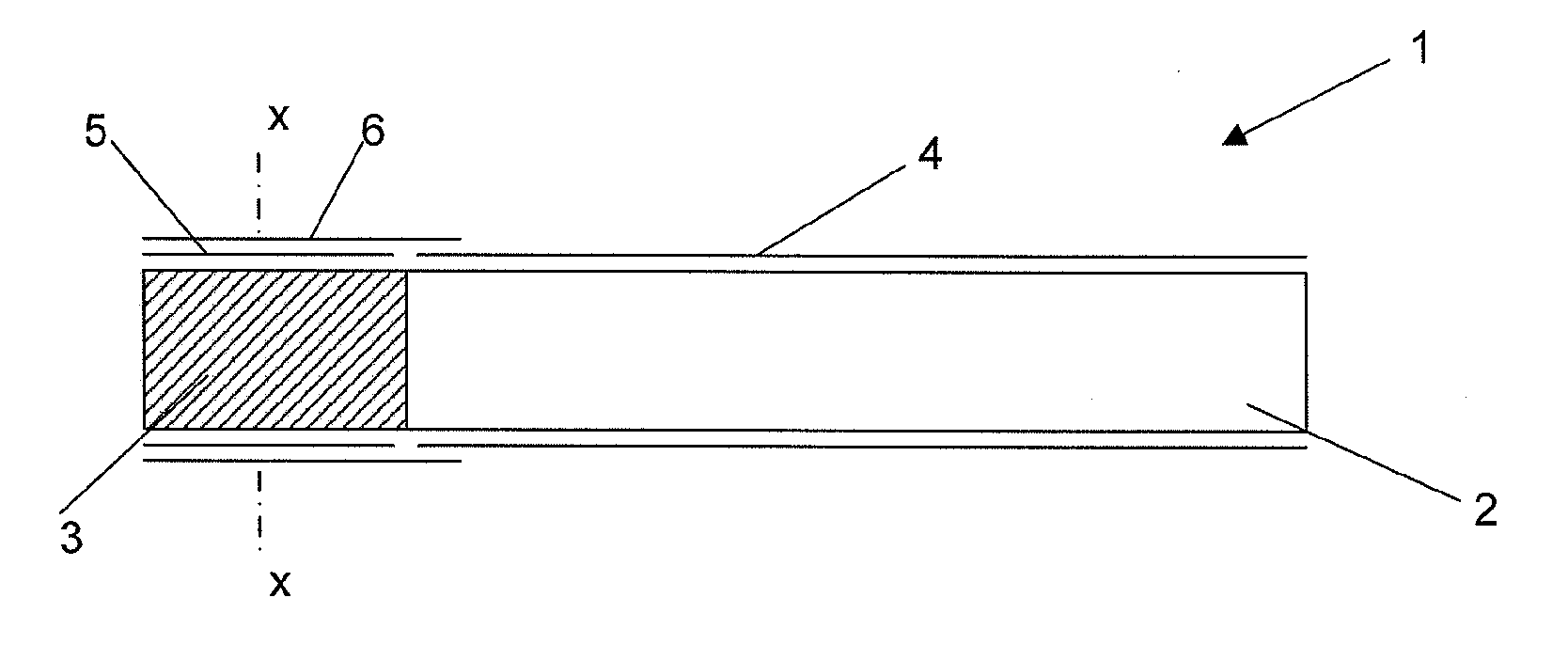

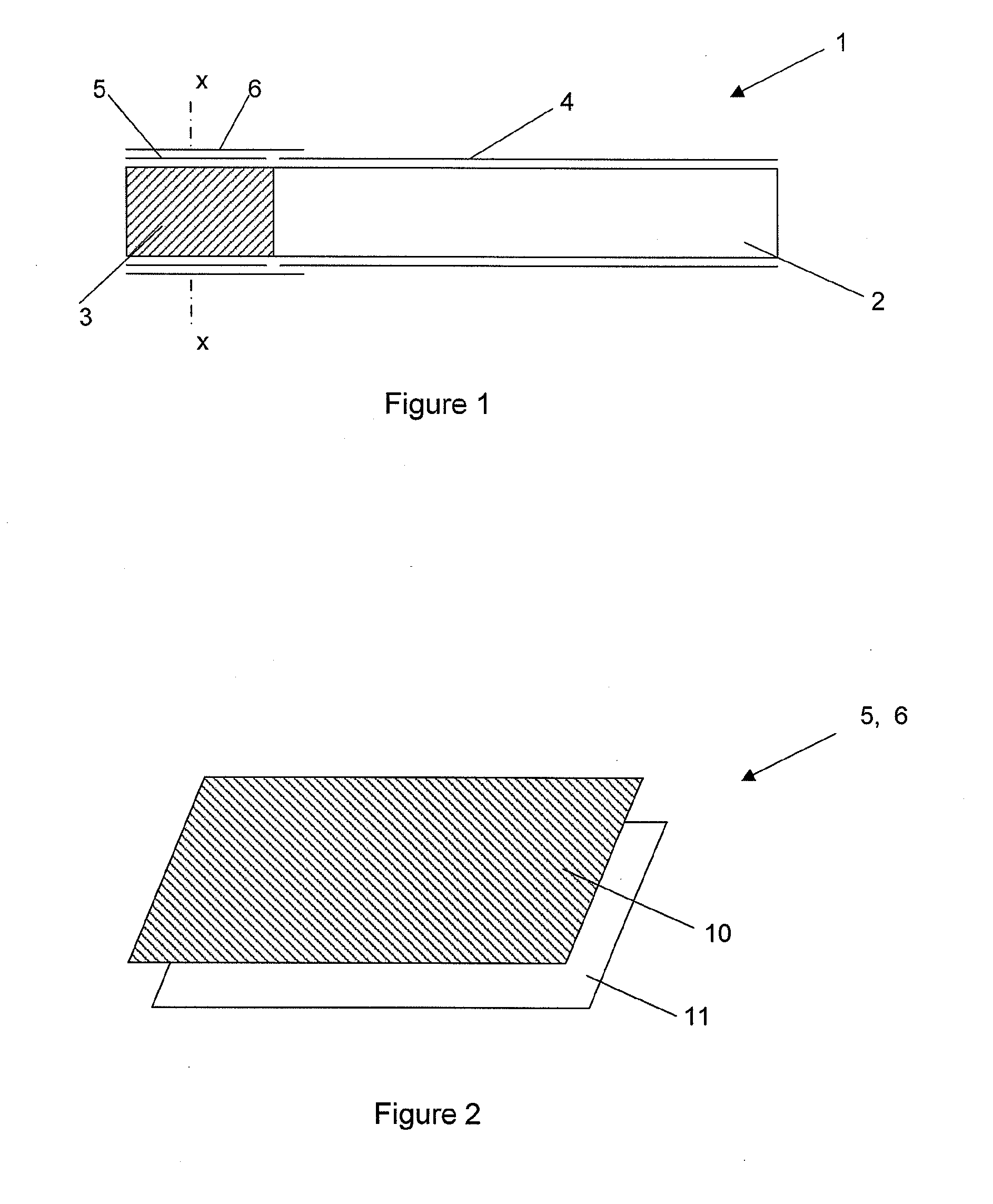

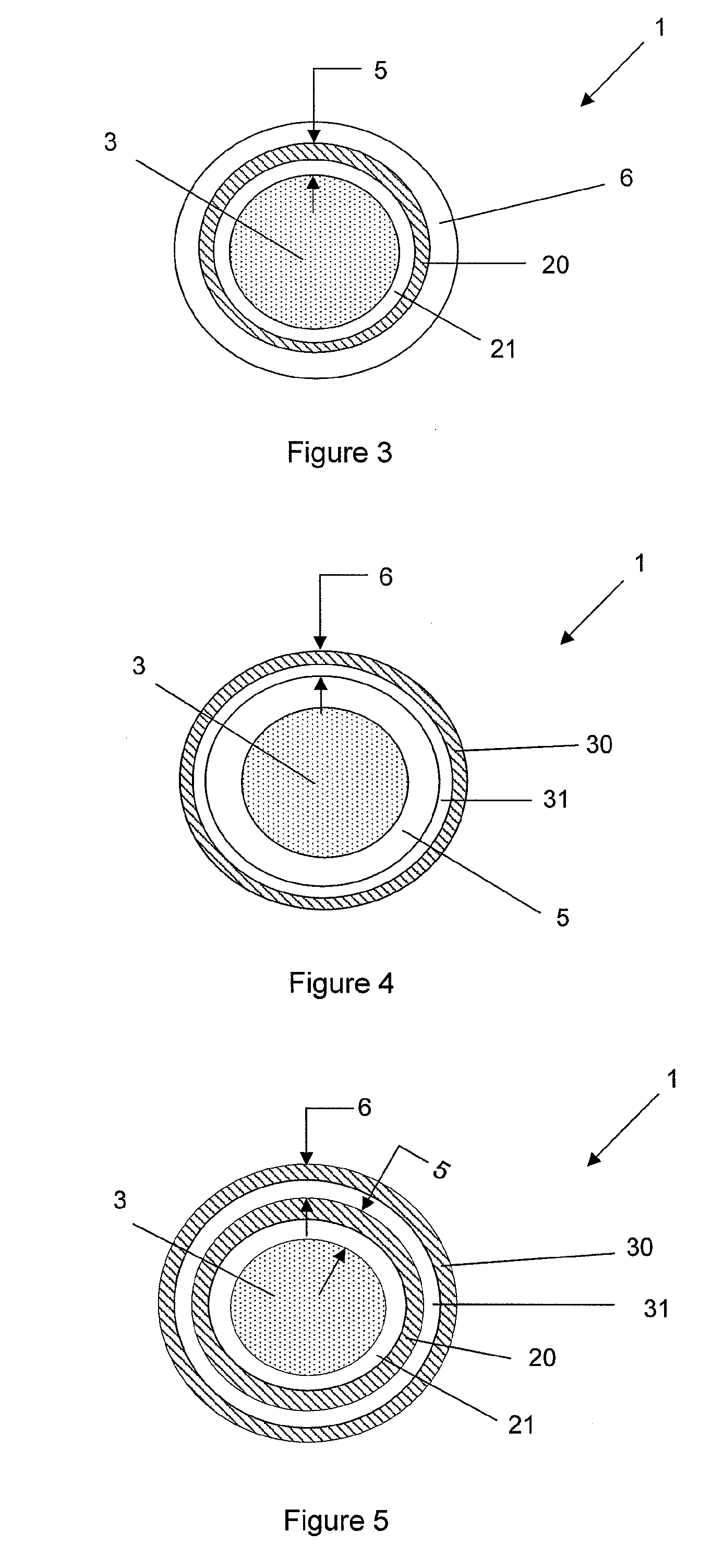

[0060]FIG. 1 shows a smoking article 1 in longitudinal cross-section. The smoking article 1 comprises a rod 2 of smokable material enwrapped by a wrapper 4 and a filter rod 3. The filter rod 3 is positioned at a mouth end of the smoking article 1. The filter rod 3 is enwrapped by a plug wrap 5. The filter rod 3 is attached to the rod of smokable material 2 by a tipping paper 6. Each of the wrapper 4, the plug wrap 5 and the tipping paper 6 is made of a respective single sheet.

[0061]The plug wrap 5 extends for the entire length of the filter rod 3 in the longitudinal axis of the smoking article 1. The plug wrap 5 thus enwraps the entire radial surface of the filter rod 3.

[0062]The filter rod 3 may be a multiple filter comprising multiple sections such as, for example, a dual or triple filter. Suitable filters are well known to those skilled in the art. The filter 3 may include adsorbent material, for instance activated carbon, for the reduction of vapour phase constituents of smoke. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com