Method for the thermographic inspection of nonmetallic materials, particularly coated nonmetallic materials, as well as method for the production thereof and an object produced according to the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

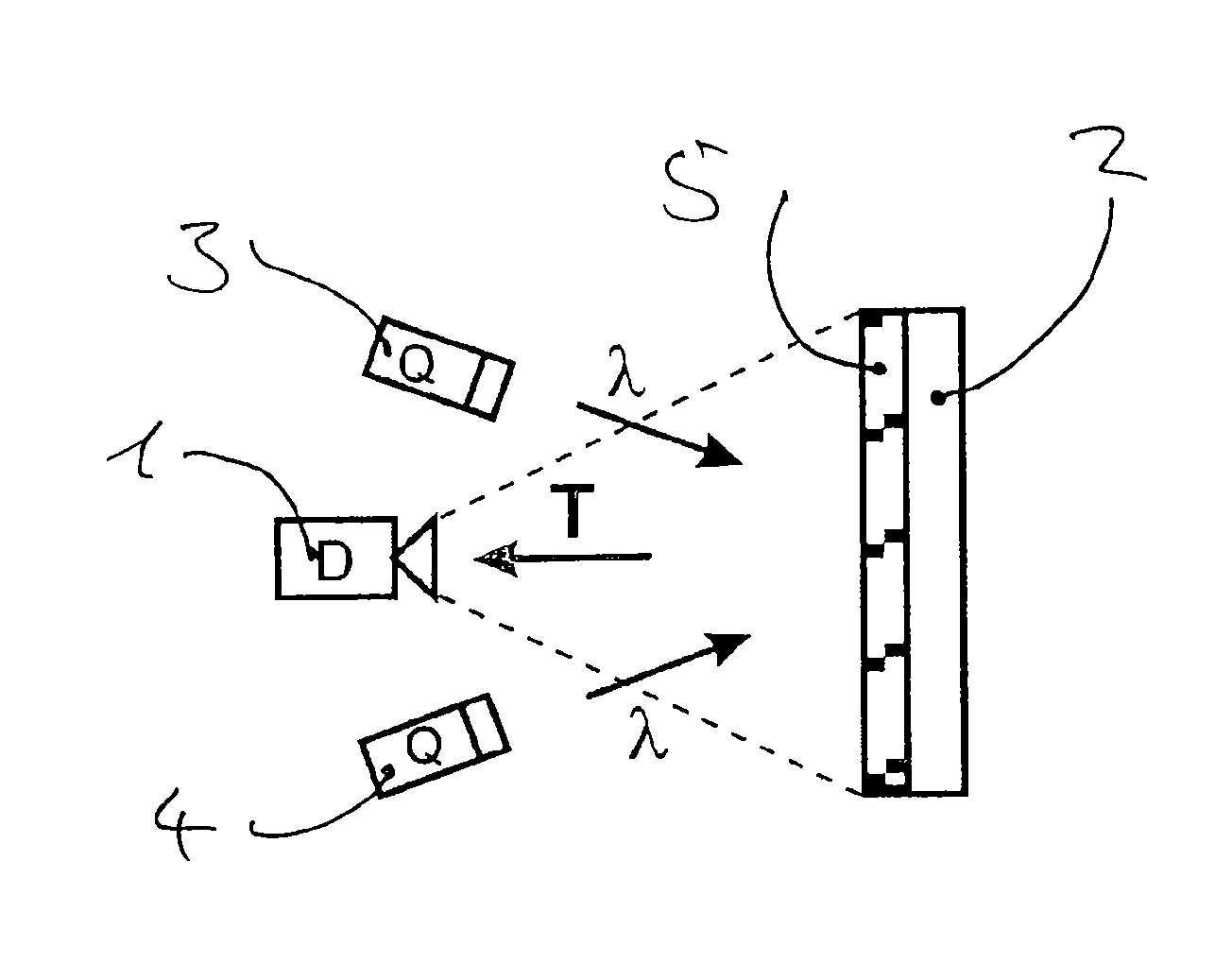

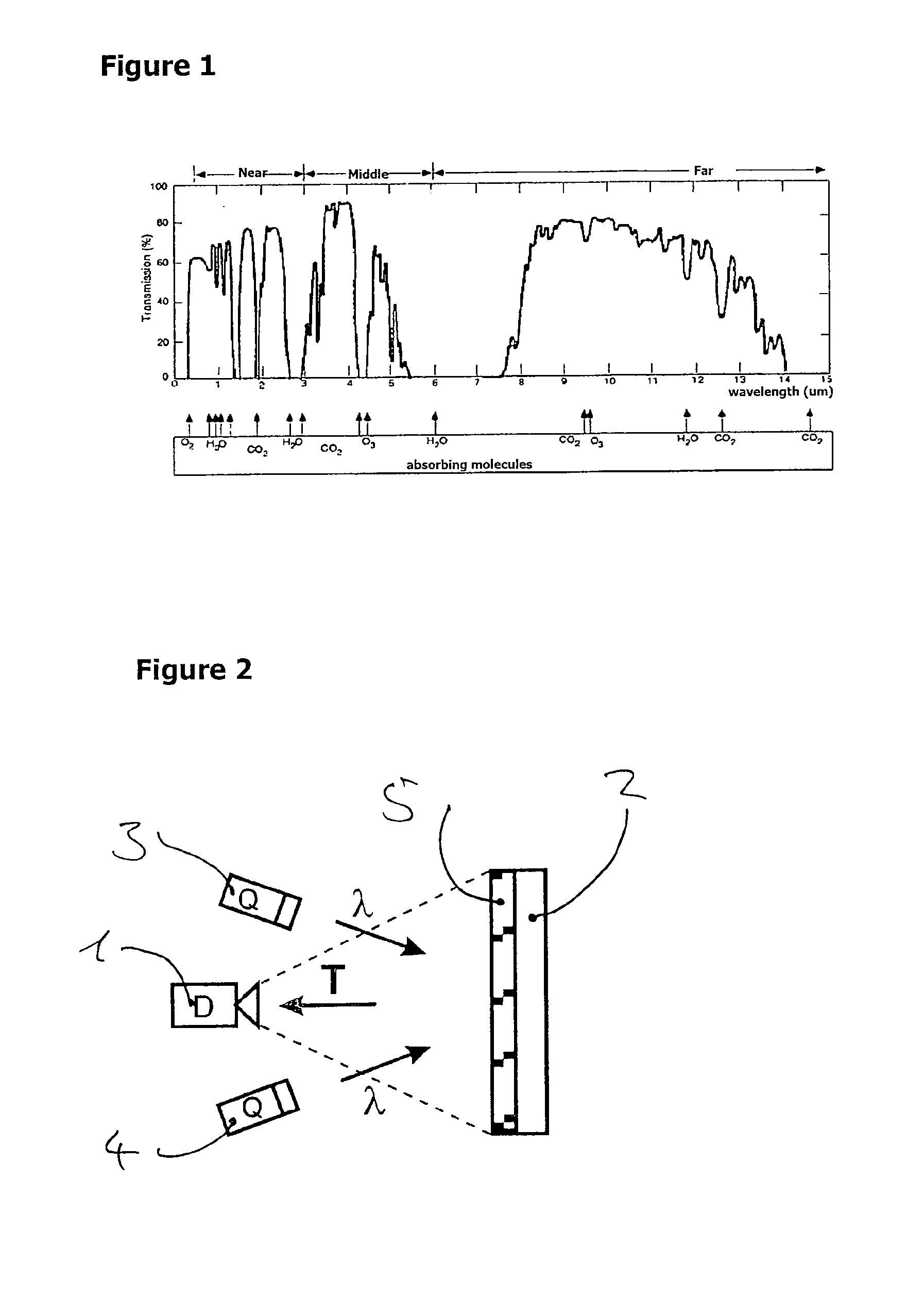

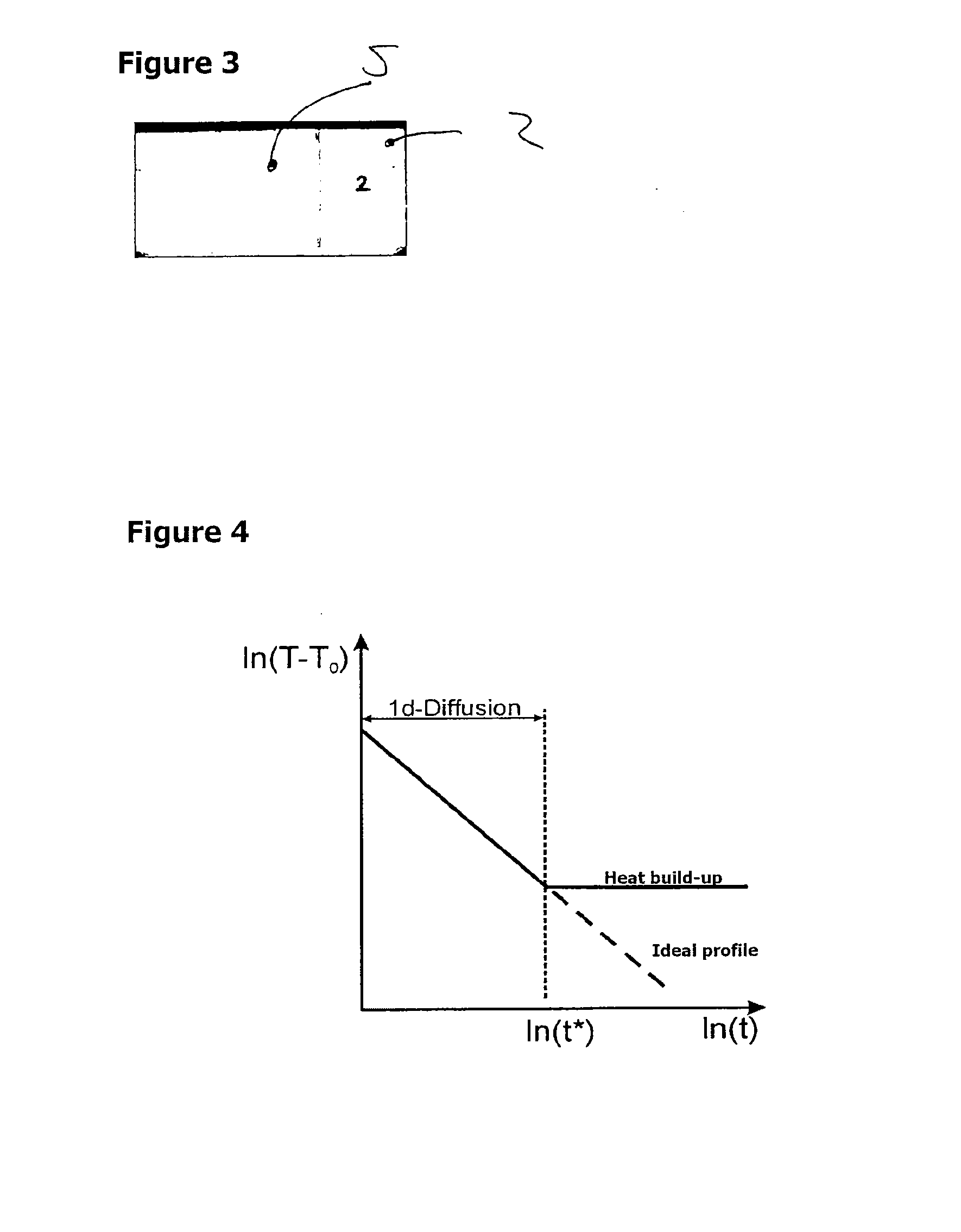

Image

Examples

Embodiment Construction

When fused quartz crucibles are coated with barrier layers, particularly with ceramic barrier layers, the layer quality, that is, the presence of a minimum layer thickness, its intactness, and the absence of cracks and detachment from the surface, take on crucial importance.

The investigation of crucibles already used for silicon production can also substantially increase their service life, if it can be established with certainty that these crucibles still have the required minimum layer thickness for the ingot production operation at all necessary sites, in particular the sites coming into contact with silicon.

However, a particularly advantageous point in time also exists when this investigation is carried out prior to the thermal fixation process of the slurry applied onto the ceramic fused quartz, particularly Quarzal, object.

For one thing, each layer can then still be investigated with certainty in terms of its layer quality prior to the thermally stressing and energy-intensive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com