Solar heating system with overheating protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

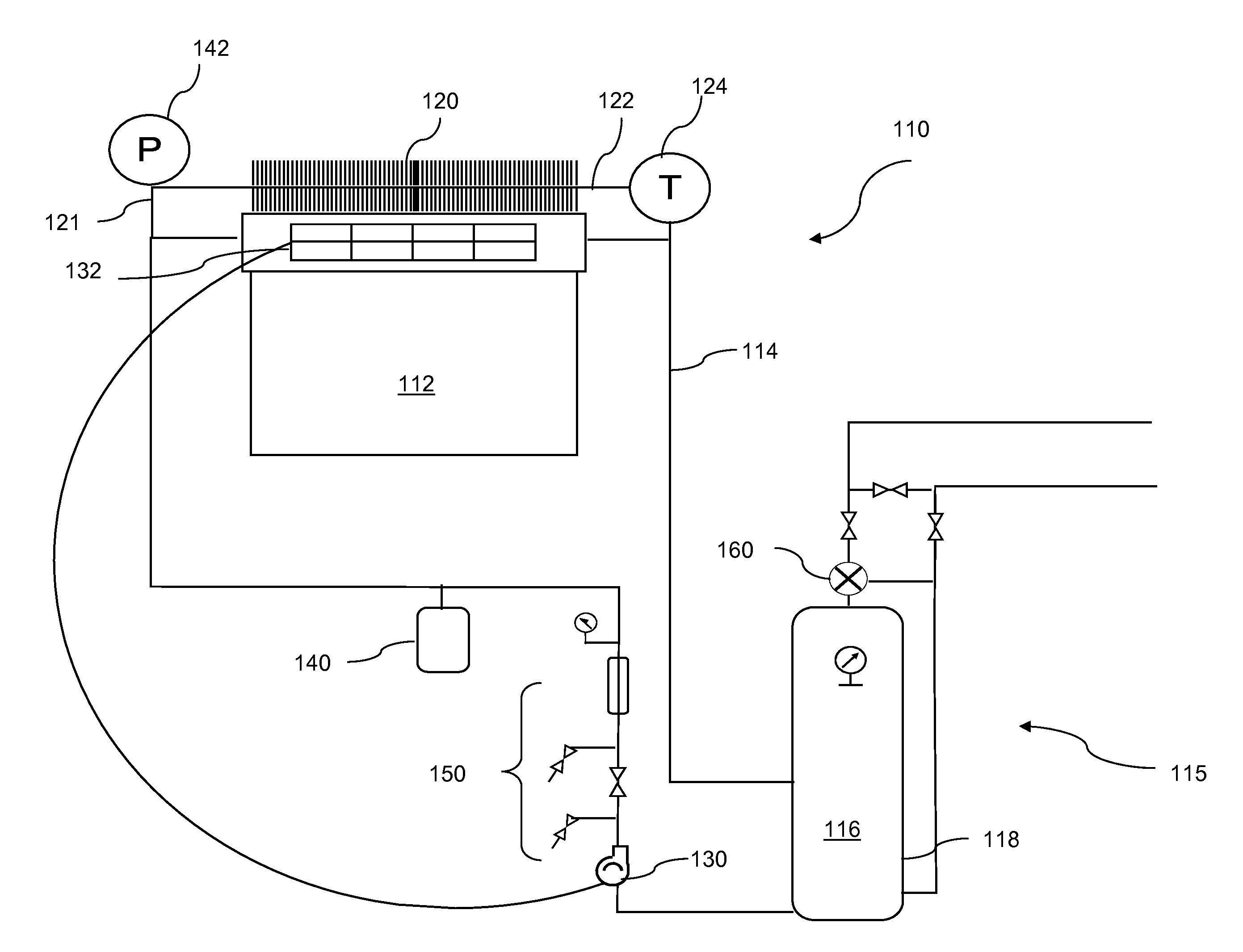

[0054]In an indirect solar water heater system, according to an embodiment of the invention and as shown schematically in FIG. 2A, a solar collector 112 comprising 30, 58 mm×1800 mm evacuated tubes, rated at a maximum thermal output of about 7400 BTU per hour, available from Jiangsu Sunrain Co. Ltd., was mounted to the roof of a structure. The collector assembly was mounted at an angle of about 70 degrees from horizontal to ensure solar gain was maximized during the winter and minimized during the summer as is known in the art.

[0055]The solar collector 112 was thermally and fluidly connected to a 300 L (80 USG) hot water tank 118 located within the structure, using ¾″ cross-linked polyethylene (PEX) pipe and fittings, for forming the heat exchange circuit 114, through which a working fluid was circulated. All piping in the system was insulated to reduce energy losses.

[0056]The working fluid for circulation through the heat exchange circuit comprised distilled water mixed at about 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com