Reinforcement and/or anchor bolt

a technology of anchor bolts and bolts, applied in the direction of anchoring bolts, earthwork drilling and mining, mining structures, etc., can solve the problems of long curing time, high cost of chemical anchor systems, and inability to meet the needs of mining operations, and achieve the effect of inexpensive and reliable anchoring to the bedrock and little technical effor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

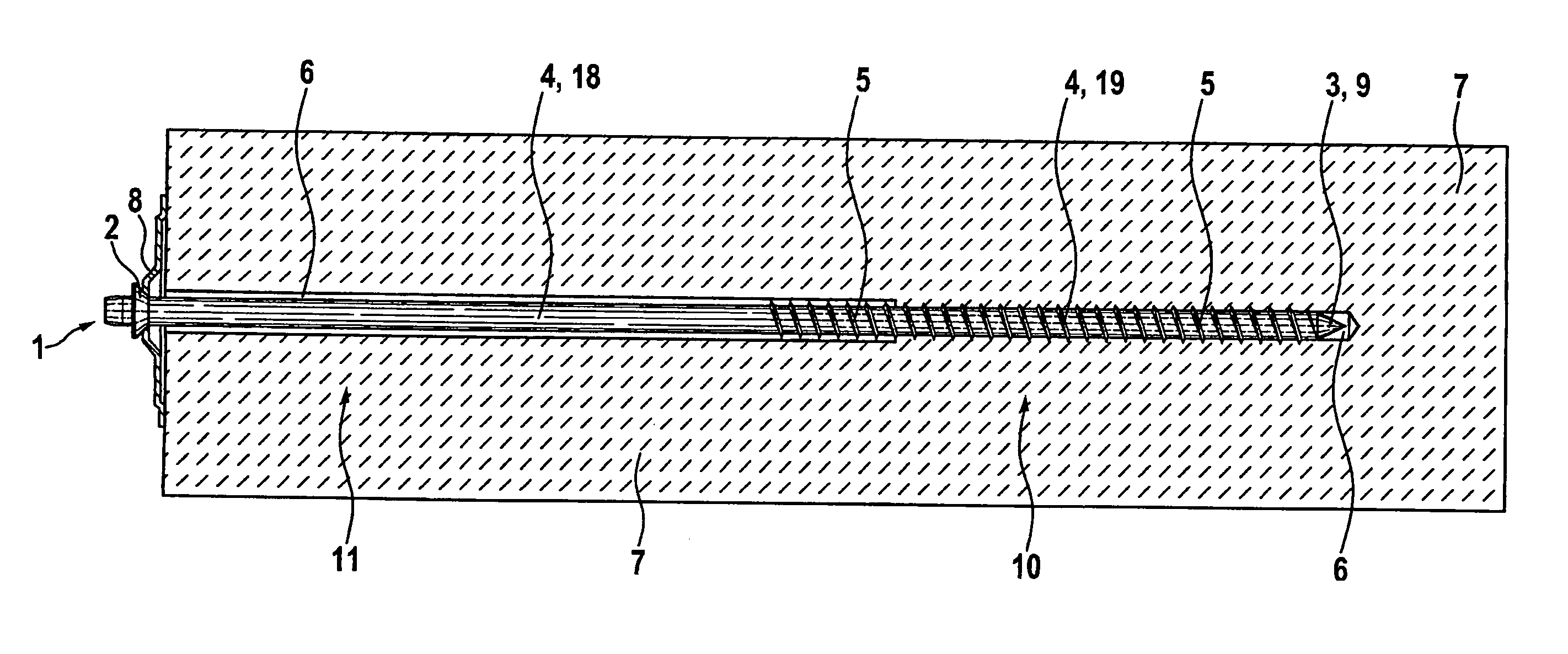

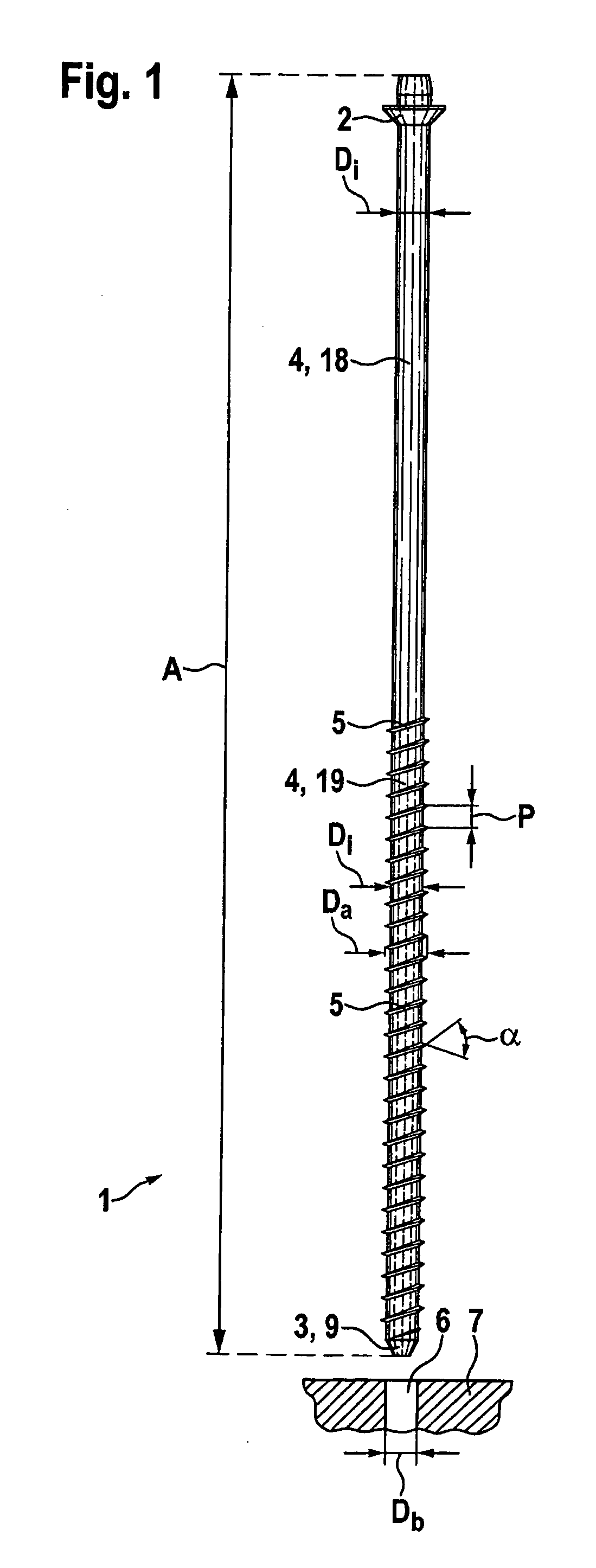

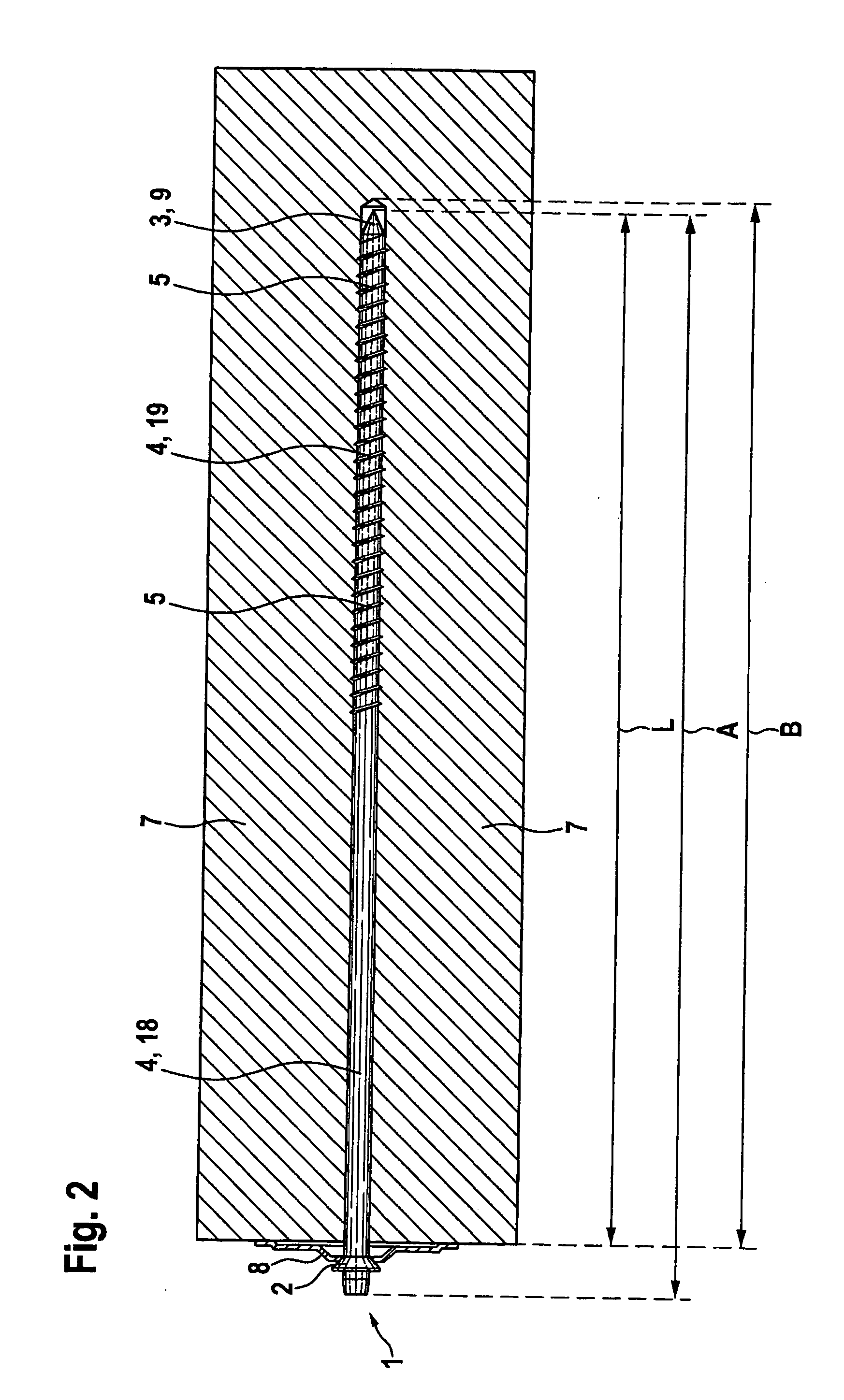

[0035]FIG. 2 shows an arrangement of the reinforcement and / or anchor bolt 1 in a bore hole 6 that has been drilled in the bedrock 7. The reinforcement and / or anchor bolt 1 is configured in the area of the bolt head 2 on the bolt shaft 18 in such a way that said bolt shaft does not have a thread 5, and in another section of the bolt shaft 4 on the bolt end 3, it has a thread 5, or else a thread 5 is formed on the bolt shaft 19. Here, the outer diameter Da of the reinforcement and / or anchor bolt 1 is 20% to 30% larger than the diameter Db of the bore hole 6. After the bore hole 6 has been drilled, for example, with a drill rod 12, whereby the bore hole 6 has a constant diameter Db, the reinforcement and / or anchor bolt 1 is screwed into the bore hole 6 in that a torque is applied to the bolt head 2. Due to the larger outer diameter Da of the reinforcement and / or anchor bolt 1 relative to the diameter Db of the bore hole 6, the thread 5 cuts its way into the bedrock 7 and a positive con...

second embodiment

[0039]FIG. 5 shows a perspective view of the drill rod 12 for drilling a bore hole 6 with a varying diameter Db as shown for the second embodiment in FIG. 3. The drill rod 12 has a drilling crown 13, a stabilizer 14, a first boring bar 15 having a small diameter, a boring tool 16 and a second boring bar 17 having a large diameter. Here, for example, the drilling crown 13, the stabilizer 14 and the first boring bar 15 have a diameter of 15 mm, the boring tool 16 has a diameter of 32 mm, and the second boring bar 17 has a diameter of 18 mm. The diameter of the boring tool 16 is thus larger than the diameter of the second boring bar 17, and the diameter of the second boring bar 17 is larger than the diameter of the first boring bar 15.

[0040]All in all, the reinforcement and / or anchor bolt 1 entails major advantages. The force that is to be exerted by the reinforcement and / or anchor bolt 1 into the bedrock 7 is applied by the thread 5 essentially positively into the bedrock 7. The reinf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com