Manufacturing method of wing nuts

a manufacturing method and technology of wing nuts, applied in the direction of threaded fasteners, bolts, other domestic articles, etc., can solve the problems of poor quality, inclination of fracture, and complicated process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

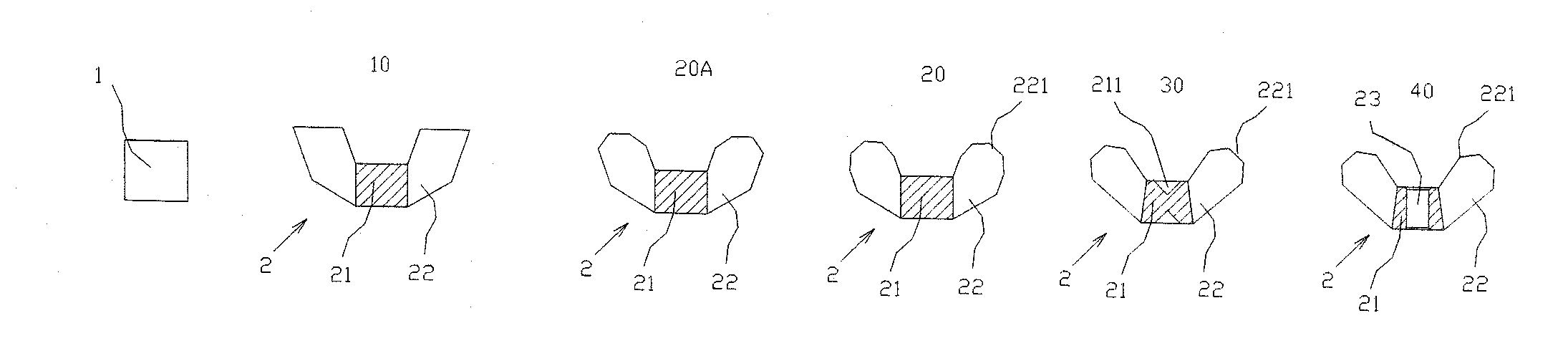

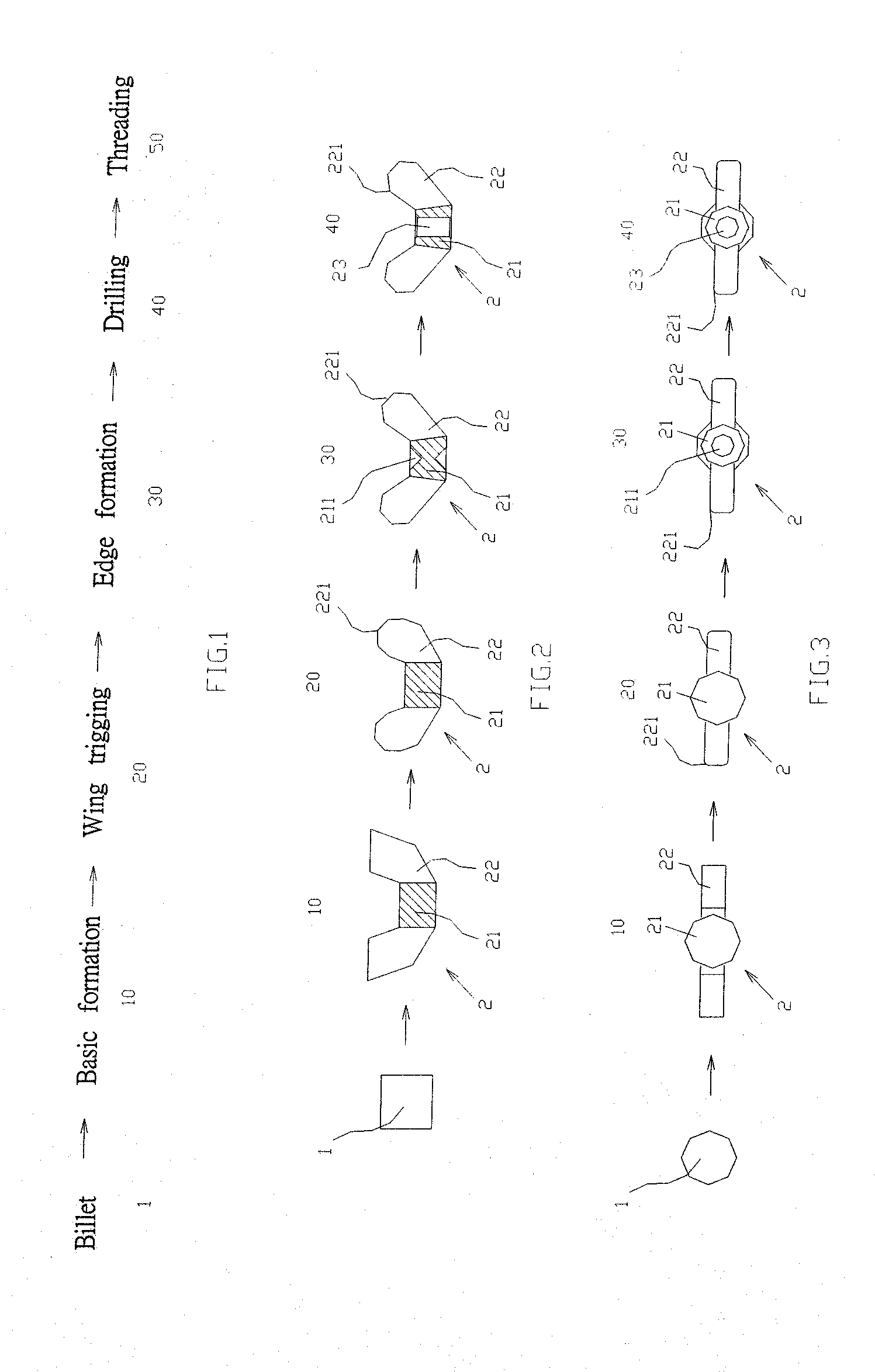

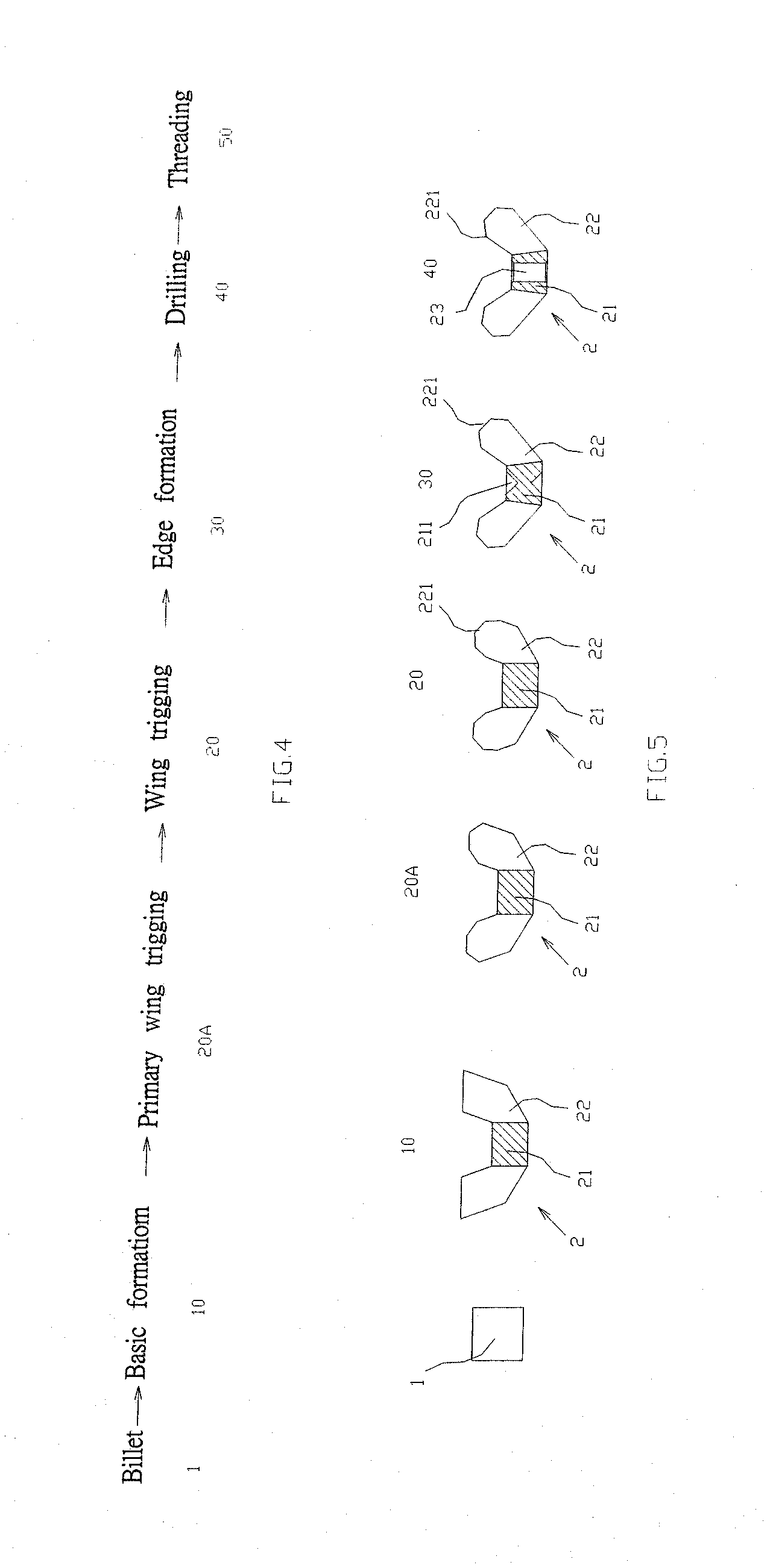

[0023]FIG. 1 shows a flowchart of a first preferred embodiment of a manufacturing method of wing nuts in the present invention. The method includes cutting a round metal wire into segments used as billets (1), and taking advantage of a special cold forging machine to directly forge the billet to become a semi-finished product by simplified steps of a basic formation (10), a wing trigging (20) and an edge formation (30). The semi-finished product is then automatically done with a drilling (40) and a threading (50) to become a final product.

[0024]FIGS. 2 and 3 show a wing nut made by the steps of the manufacturing method.

[0025]In the step of the basic formation (10), the billet (1) is directly forged to become a primary body (2) by means of a basic wing nut mold. The primary body (2) consists of an intermediate head (21) and two curved wings (22) connected with two ends of the intermediate head (21) respectively. The primary body (2) is removed to next stage by a clamp.

[0026]In the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com