Superconducting motor

a superconducting motor and superconducting technology, applied in the direction of indirect heat exchangers, air heaters, light and heating apparatus, etc., can solve the problems of difficult uniform cooling, large circumferential and axial temperature gradients, and take a long time to cool all the coils to the target ultralow temperature, etc., to achieve the effect of cooling the phase coils down

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

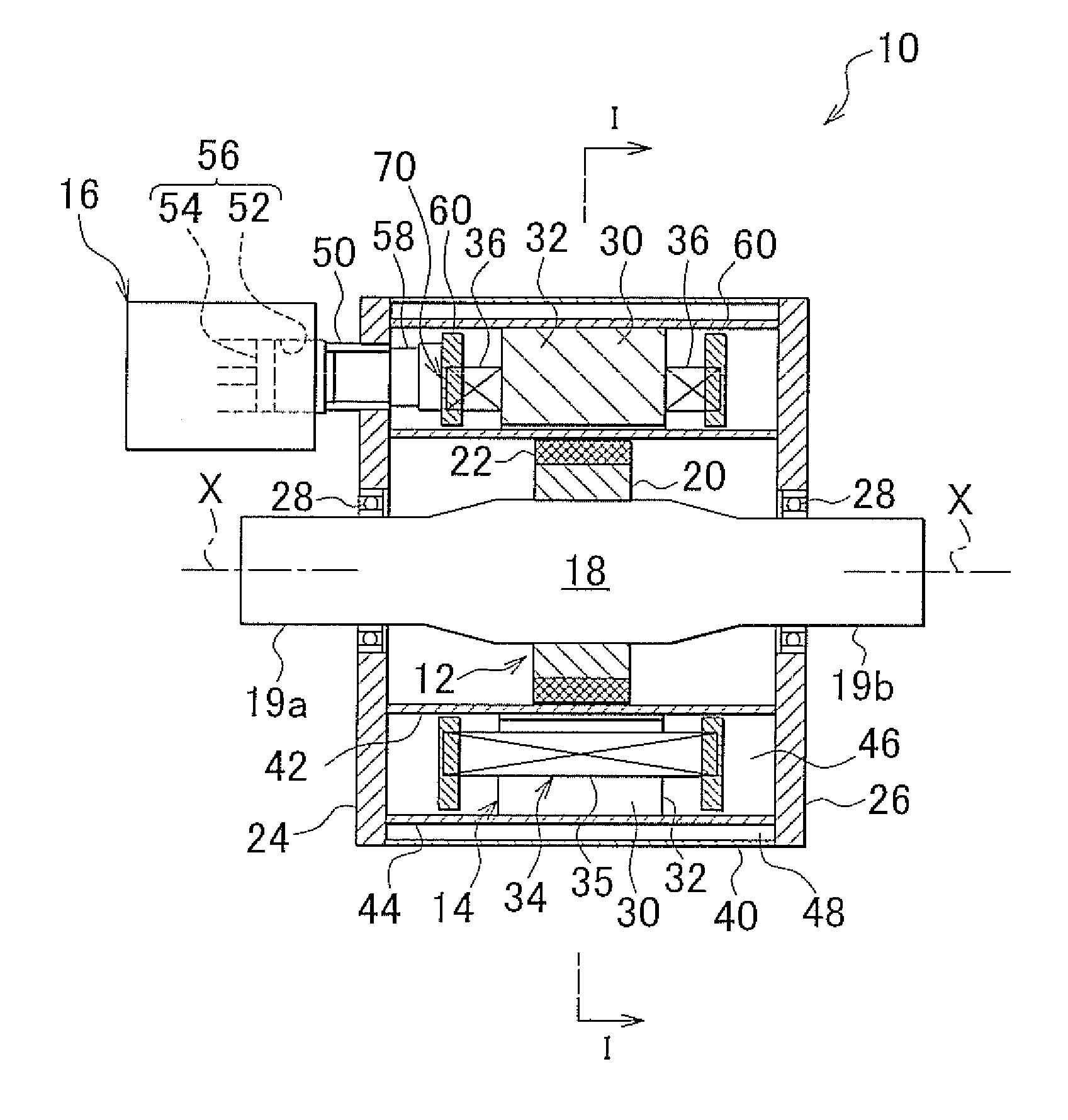

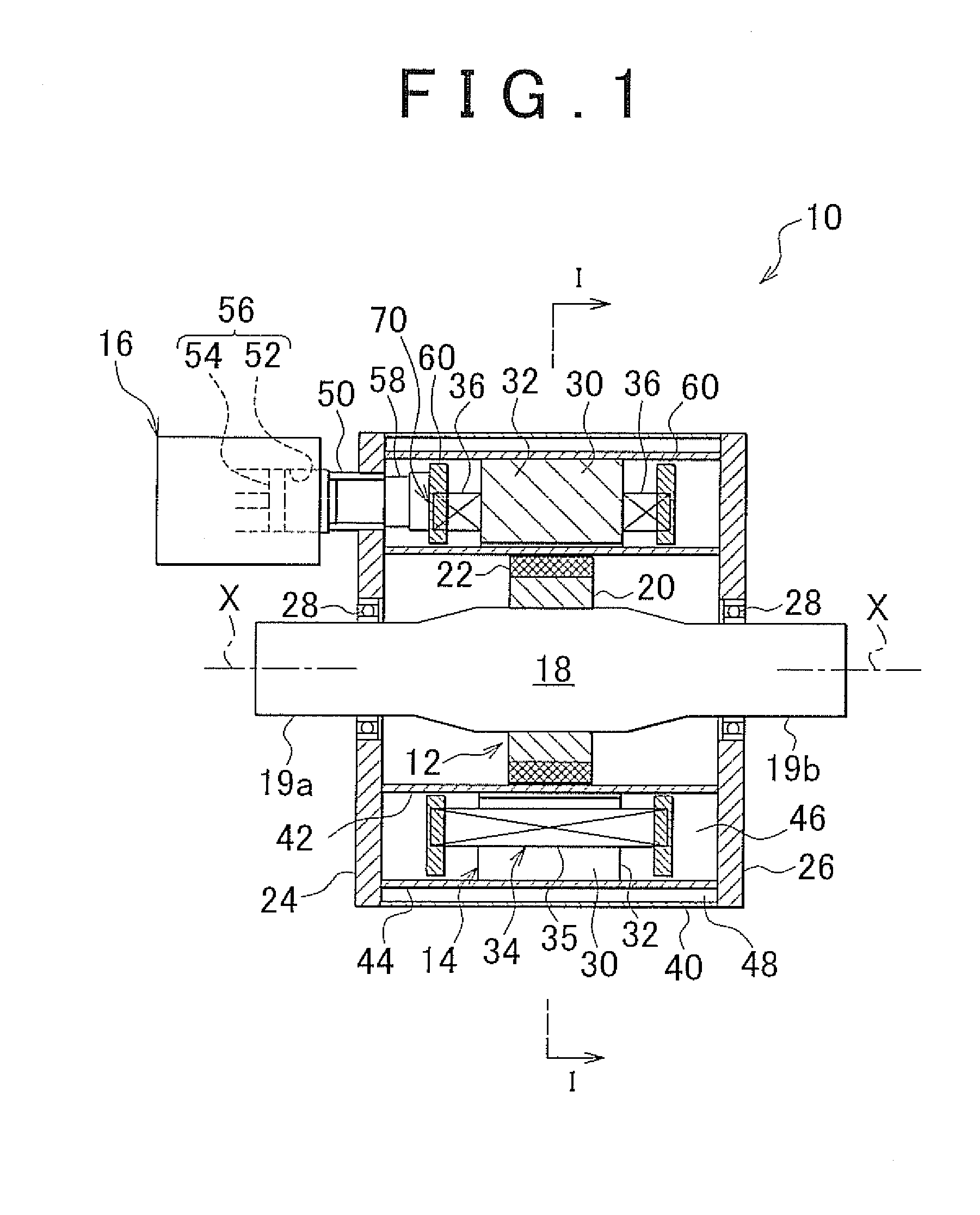

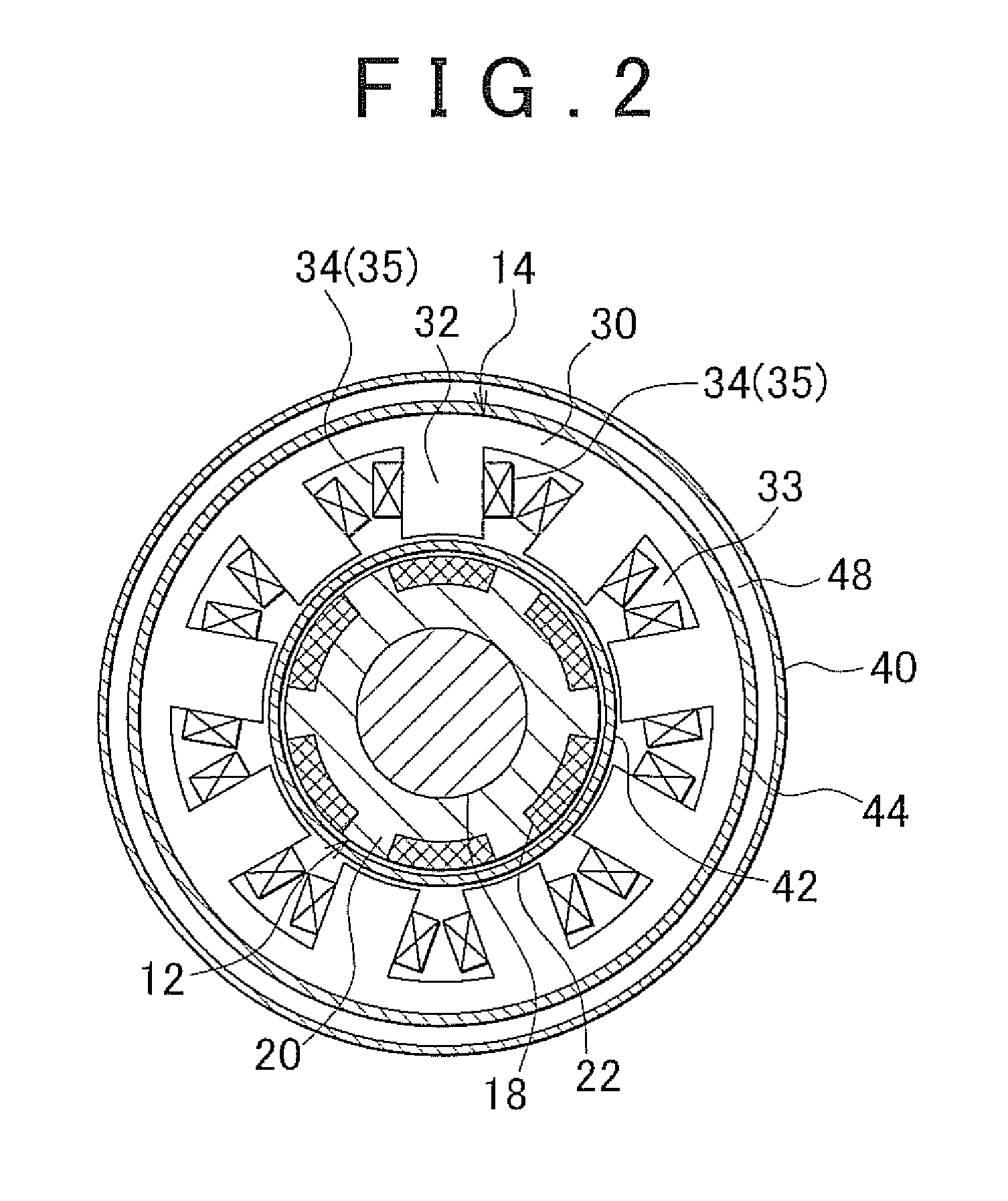

[0031]FIG. 1 is a sectional view of a superconducting motor 10 showing the invention, which is taken along the axial direction of the superconducting motor 10, and which also shows part of the side faces of the superconducting motor 10. FIG. 2 is a sectional view of the superconducting motor 10 that is taken along the line I-I shown in FIG. 1 (note that the hatching of the stator core is omitted in this view). The superconducting motor 10 has a rotor 12 that is rotatably supported, a stator 14 that is generally cylindrical and is arranged so as to surround the outer periphery of the rotor 12, and a refrigerator 16 that is fixed on an axial end face of the superconducting motor 10. Note that, in the following descriptions on the respective example embodiments, each direction that extends along a rotational axis X of a rotor shaft 18 that passes through the center of the rotor 12 will be referred to as “axial direction (motor-axis direction)”, each radial direction intersecting the ro...

second embodiment

[0074]FIG. 10 shows a sectional view of the superconducting motor 10a of the second embodiment that is taken along the axial direction thereof and also shows the side faces of some portions of the superconducting motor 10a. FIG. 11 is a view schematically illustrating an electric connection in the superconducting motor 10a, shown in FIG. 10, in which the phase coils 34U, 34V, and 34W are connected to each other at two neutral points 70a and 70b.

[0075]The superconducting motor 10a of the second embodiment has a refrigerator 17 in addition to the refrigerator 16. In the following descriptions, the refrigerators 16 and 17 will be referred to as “the first refrigerator 16” and “the second refrigerator 17”, respectively. The second refrigerator 17 is attached to the endplate 26 located at the other axial side via a structure that is the same as that for the refrigerator 16.

[0076]The first refrigerator 16 and the second refrigerator 17 are arranged so as to face each other such that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com