Removable long-lived and reusable u-shaped hybrid nut

a hybrid nut, long-lived technology, applied in the direction of screws, threaded fasteners, fastening means, etc., can solve the problems of excessive rigidity of said known nuts, difficult positioning of nuts, and still suffer from a number of drawbacks, so as to improve the rigidity of nuts, improve the elastic behavior, and facilitate mounting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

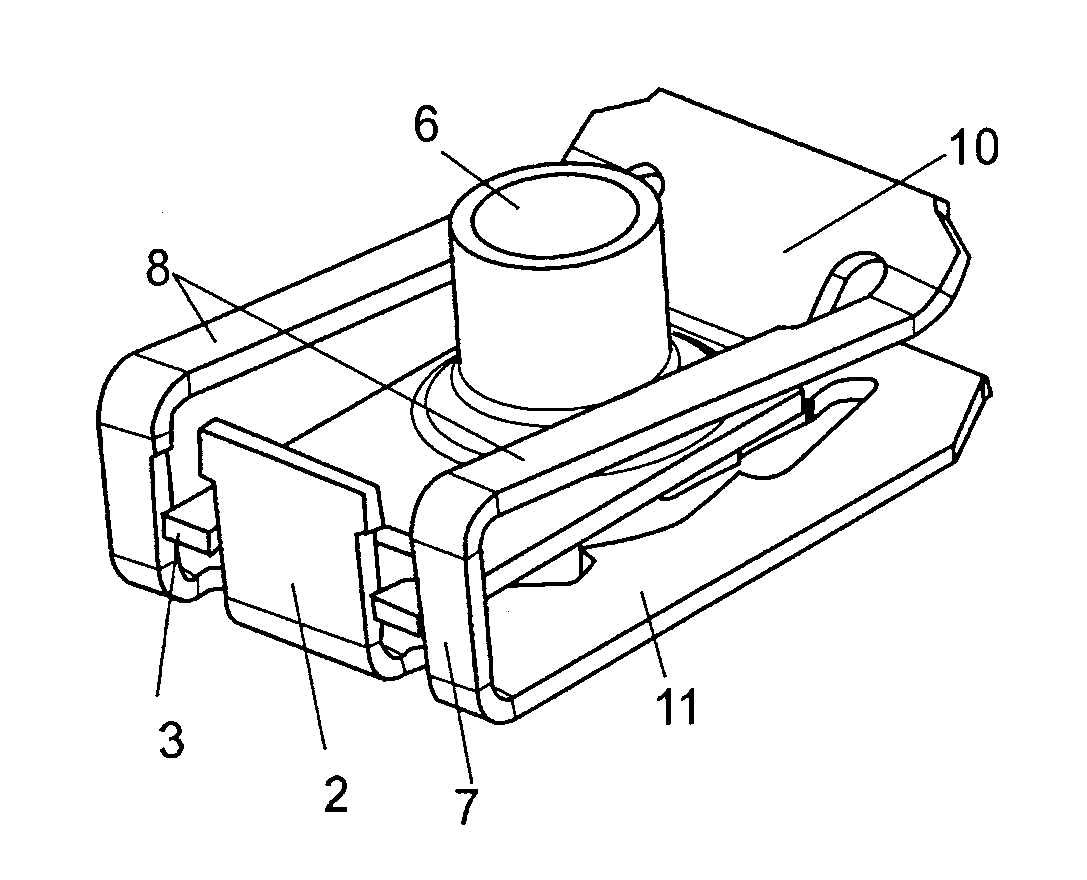

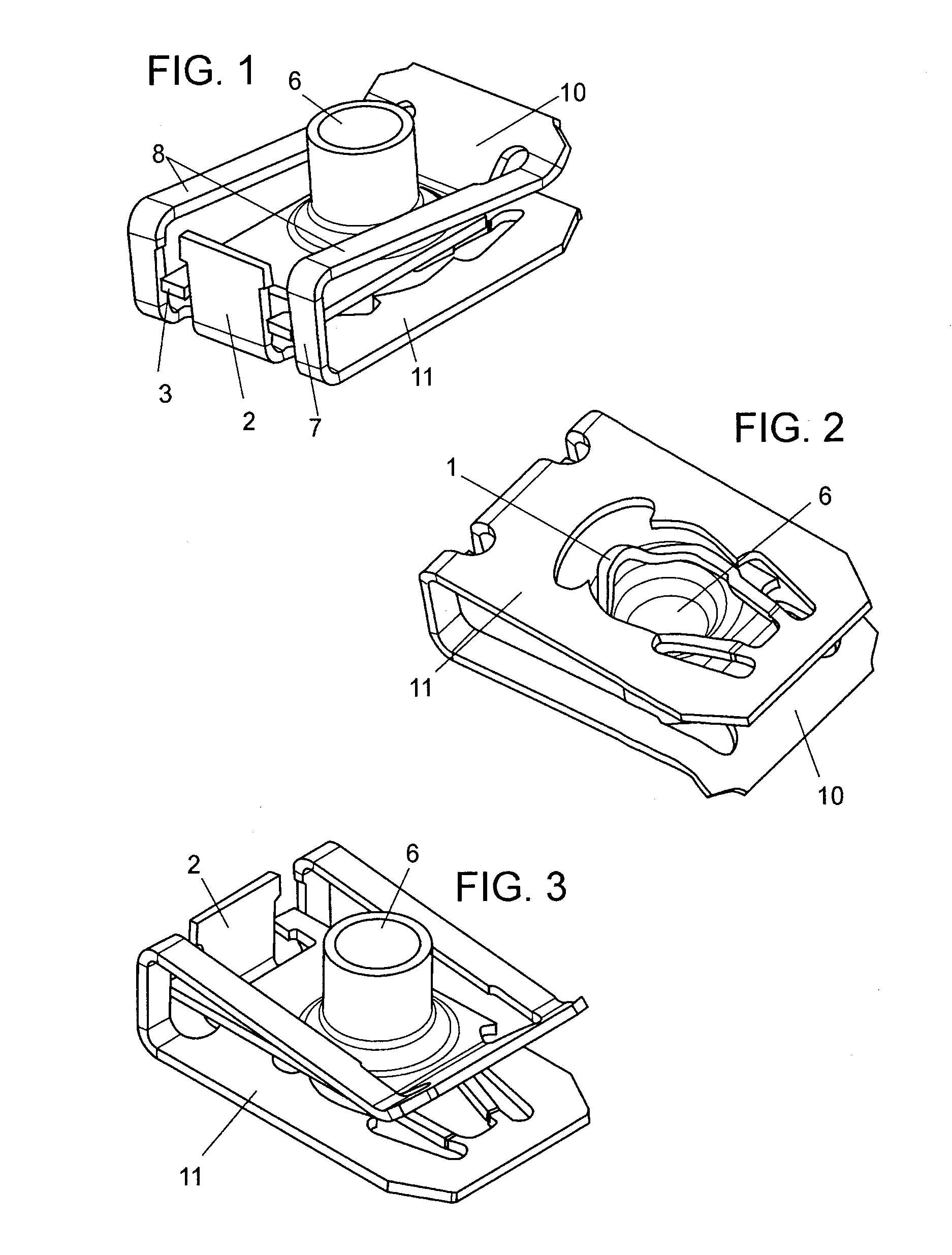

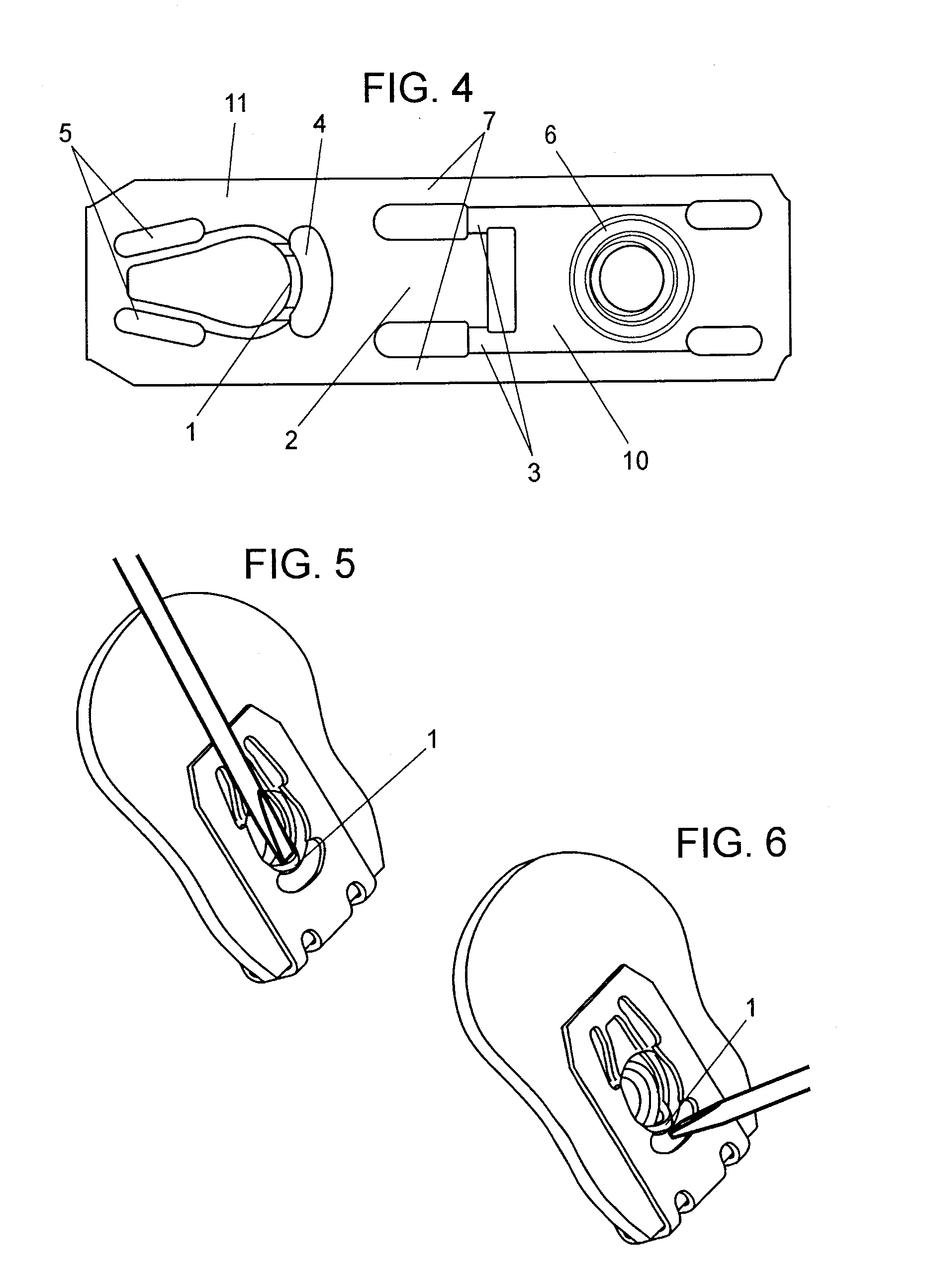

[0024]The present invention consists of a nut with a C-shaped profile, of the type formed by a punched metal sheet folded onto itself for fixing onto a panel, wherein one of the arms, i.e. the upper base (10) has, formed therein, a hole for the arrangement of a screwed device with at least one thread and wherein the other arm, i.e. the lower base (11) has, aligned with the axis of the preceding hole, another hole for receiving the screw for tightening the nut.

[0025]The nut according to the invention is preferably made of heat-treated tempered carbon steel. This feature means that it has the mechanical hardness and elasticity properties which are necessary and convenient for this type of product. In the same way it may be made of any type of material with hardness and elasticity properties which are suitable for the desired application.

[0026]As shown in FIG. 4, the nut according to the invention may be obtained from a flat strip by means of deformation and punching so as to form all ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com