Shallow flangeway rail seal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

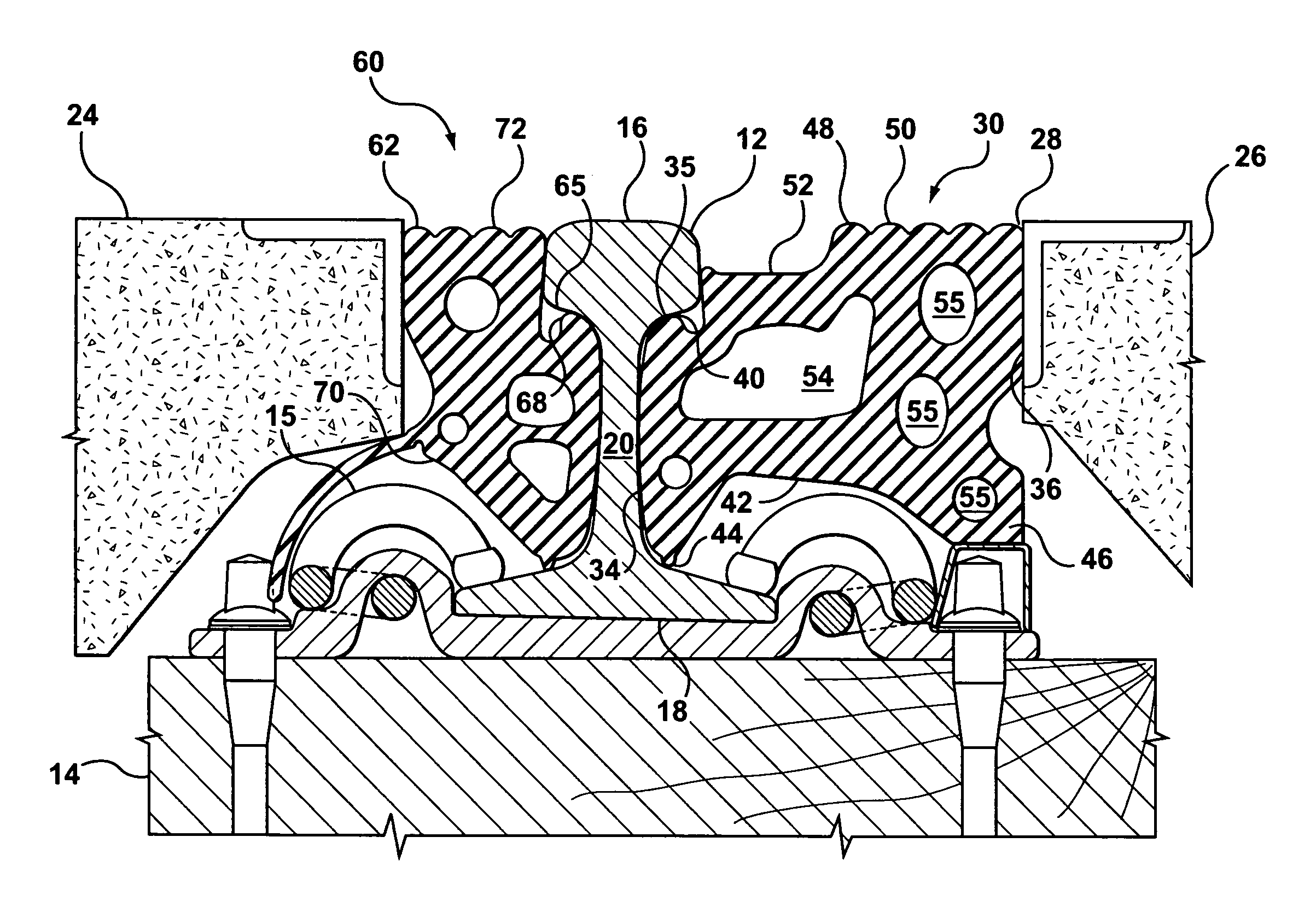

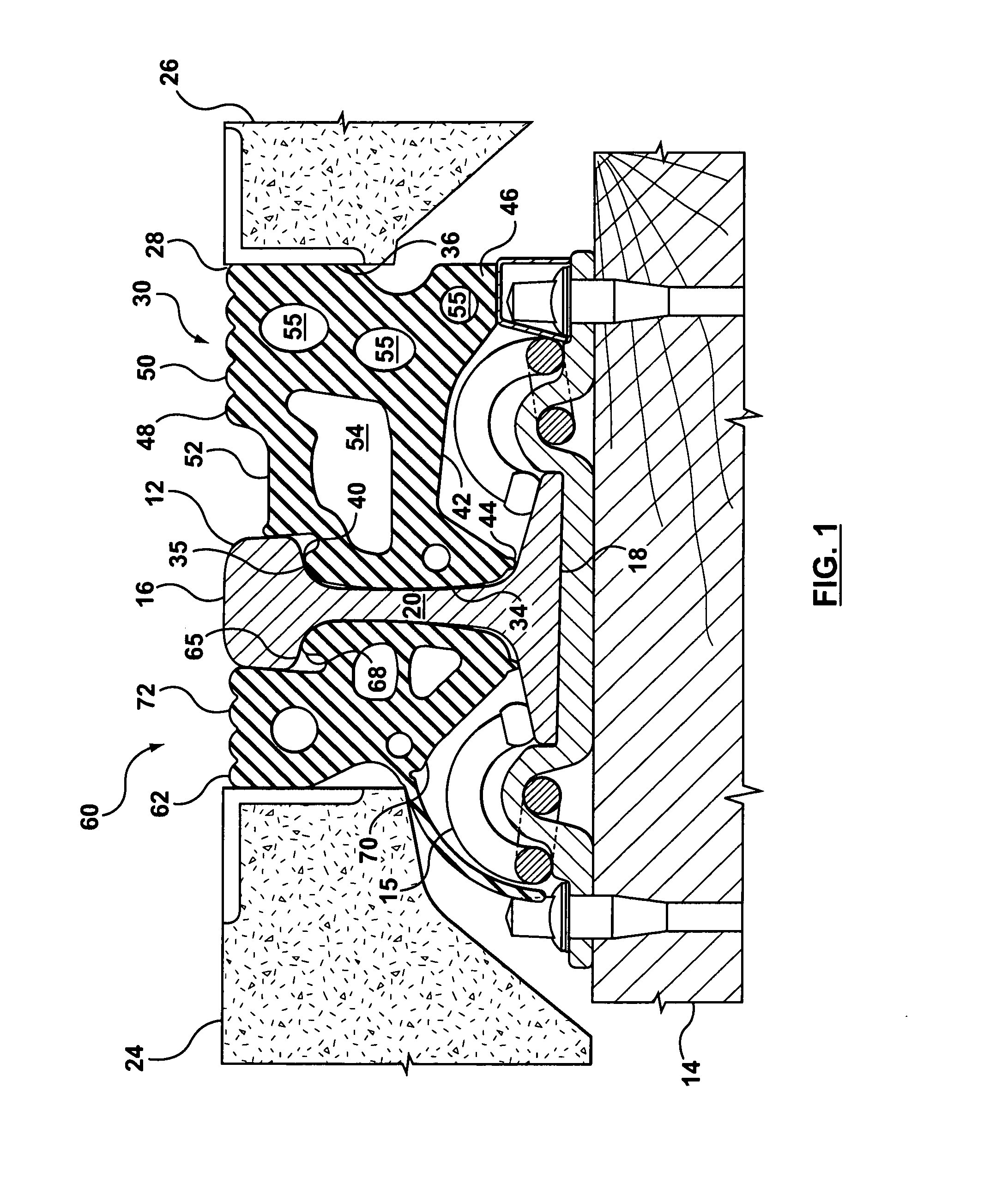

[0020]Referring now to the drawings, there is shown in FIG. 1 a cross-sectional view of a portion of a railway crossing structure incorporating a rail seal according to an example embodiment of the present disclosure. While the description may refer generally to a railway crossing structure, it will be understood that the present disclosure is not limited specifically to railroad crossings, but is also intended to cover various types of rail crossings such as streetcar crossings as well.

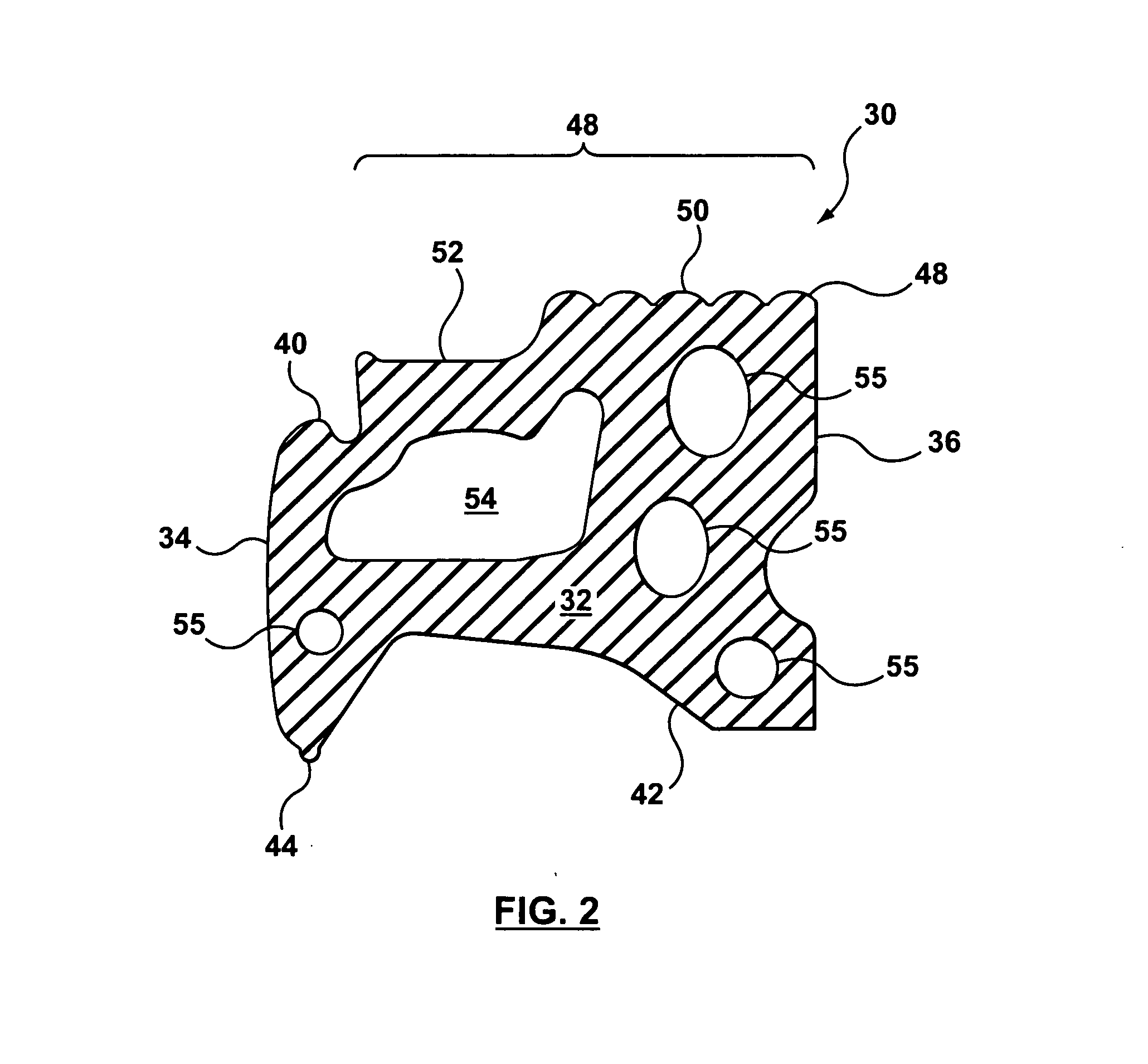

[0021]The railway crossing structure shown in FIG. 1 includes two parallel rails 12 (only one of which is shown) which are anchored in place by transverse members or rail ties 14 and secured with rail clips 15 to ensure that a consistent distance or gauge is maintained between the rails 12 along the length of the track. The rail 12 is generally in the form of a modified I-beam, with each rail 12 having a rail head 16, a base flange 18 and a web portion 20 interconnecting the rail head 16 and the base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com