Device for dispensing a liquid-to-pasty product using a metering pump having a low dead volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

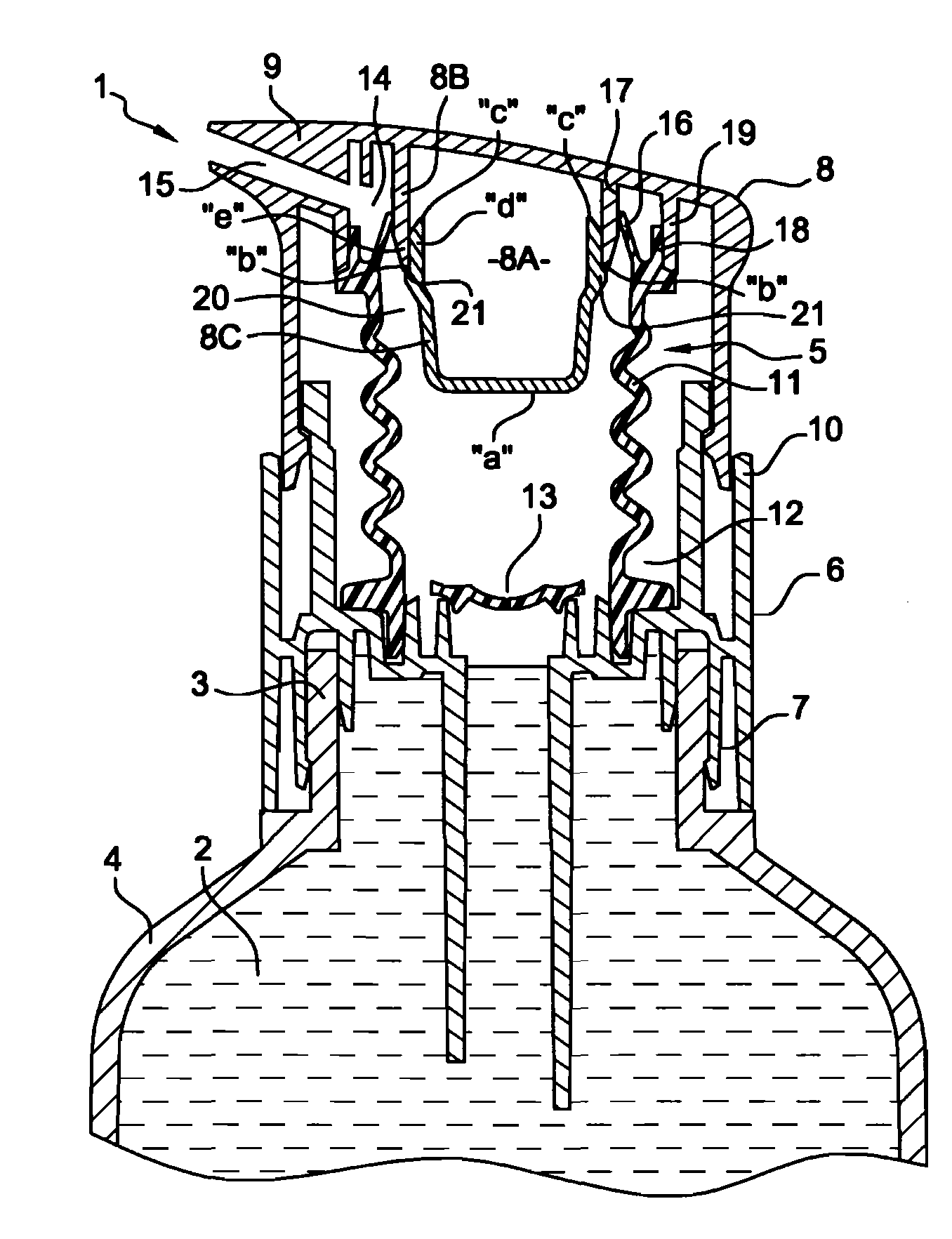

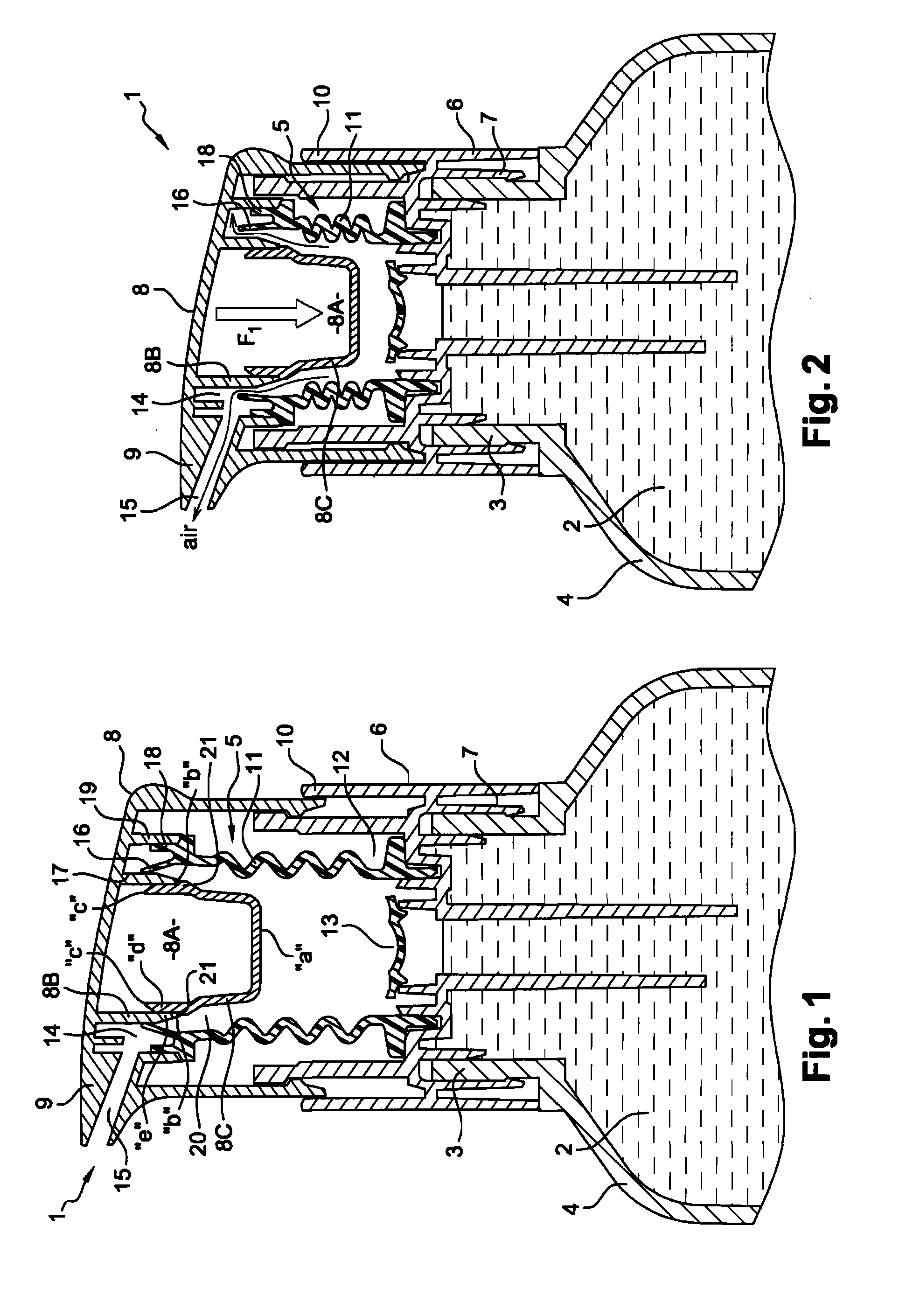

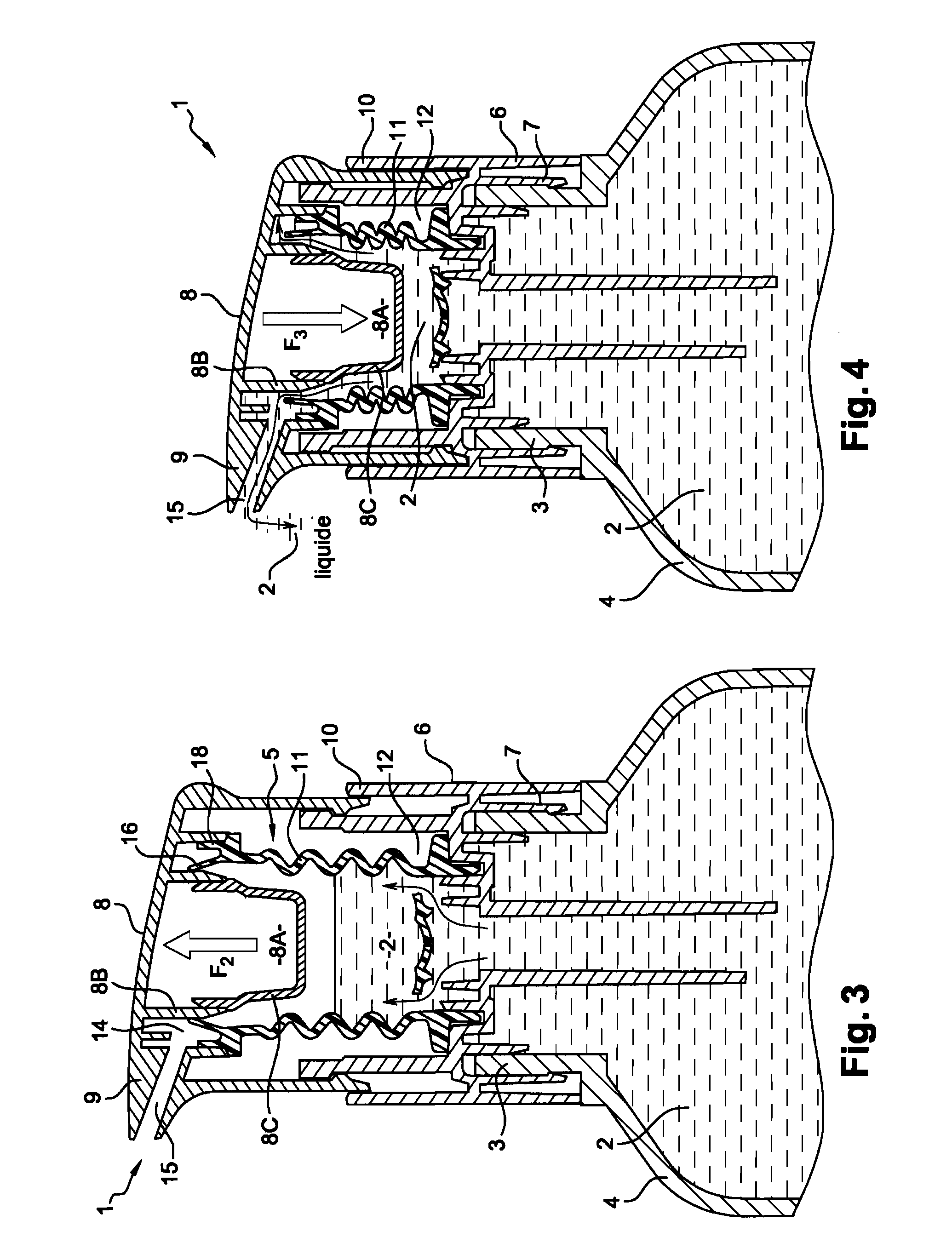

[0039]The device 1 globally designated in the figures is intended for the dispensing of a liquid-to-pasty product 2, installed at the open end 3 of a rigid container 4, and is constituted by a manual metering pump 5, allowing for the dispensing of a predetermined quantity of the product 2 to be dispensed.

[0040]In a known manner, the device 1 comprises:

[0041]a base member 6 intended to be installed by a means of hooking or of adhesion such as clipping or screwing on the container 4 by its lower end 7,

[0042]a push button 8 provided with a dispensing spout 9 mounted in a telescopic manner at the upper portion 10 of the base member 6 and able to act in pumping in relation to the latter, counter to a retaining member constituted by

[0043]an elastically deformable bellows 11 providing the sealed link between on the one hand an internal chamber 12 of the base member 6, opened towards the container 4 in order to allow for the passage of the product 2 through an opening 13, and on the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com