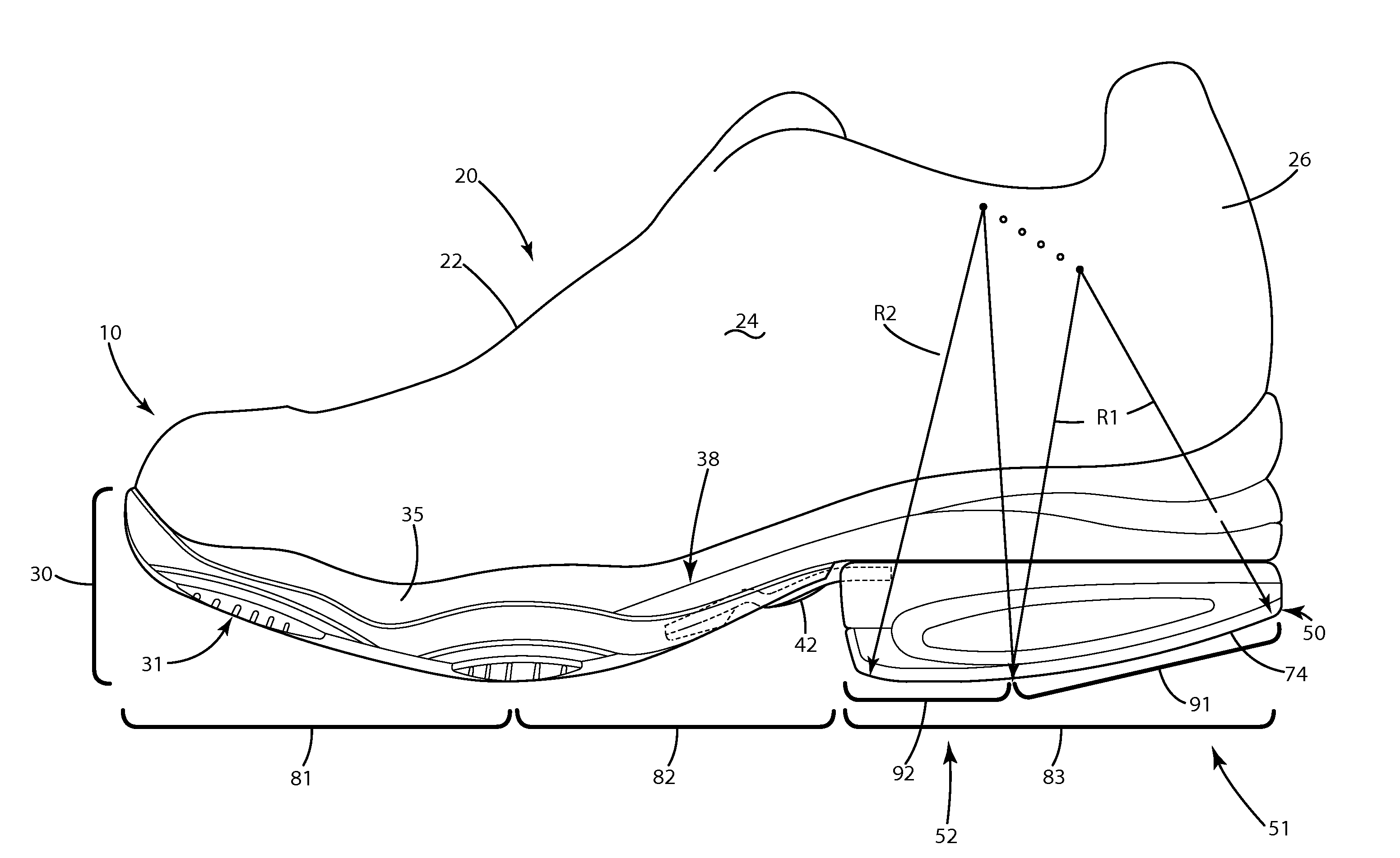

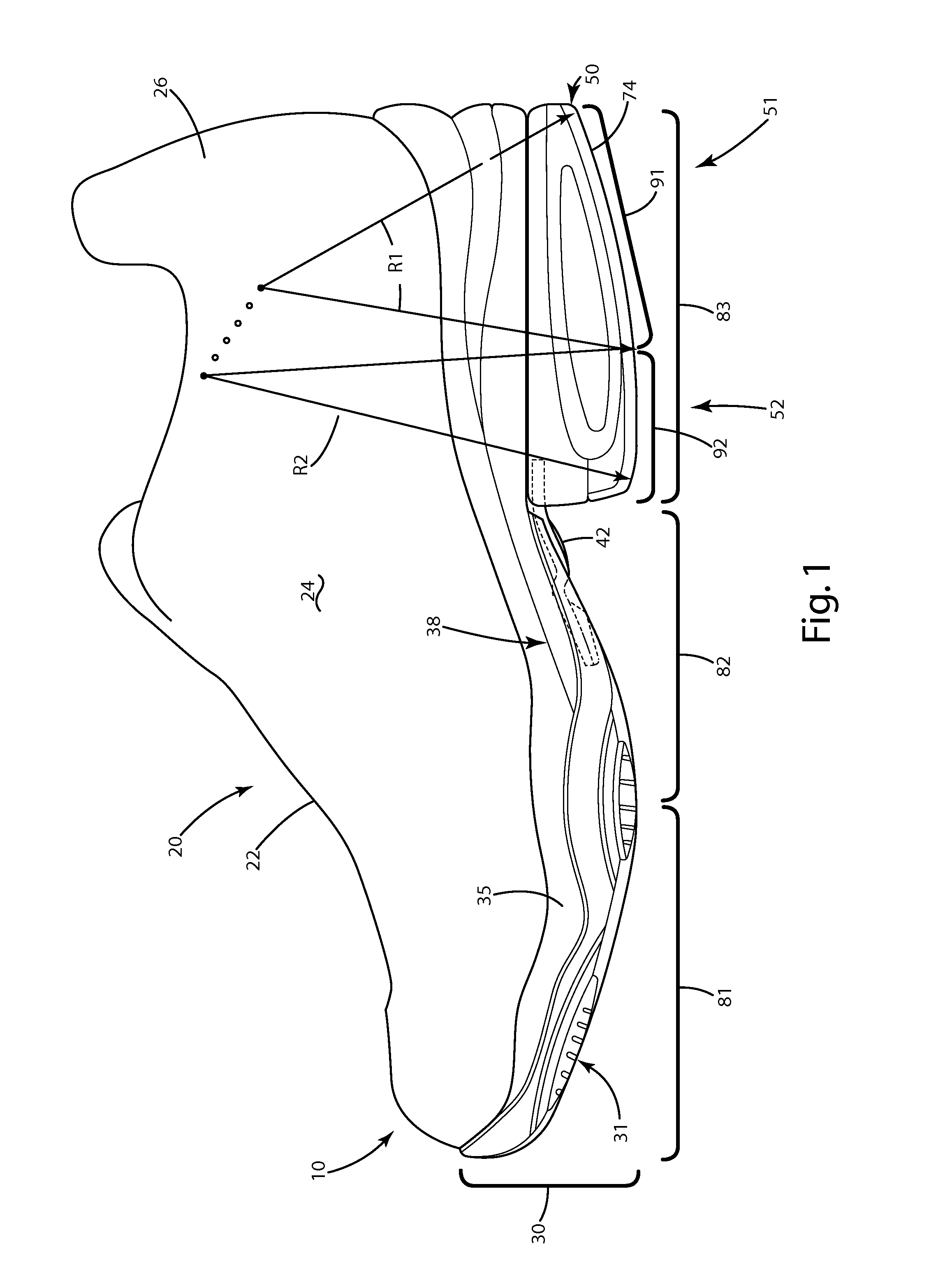

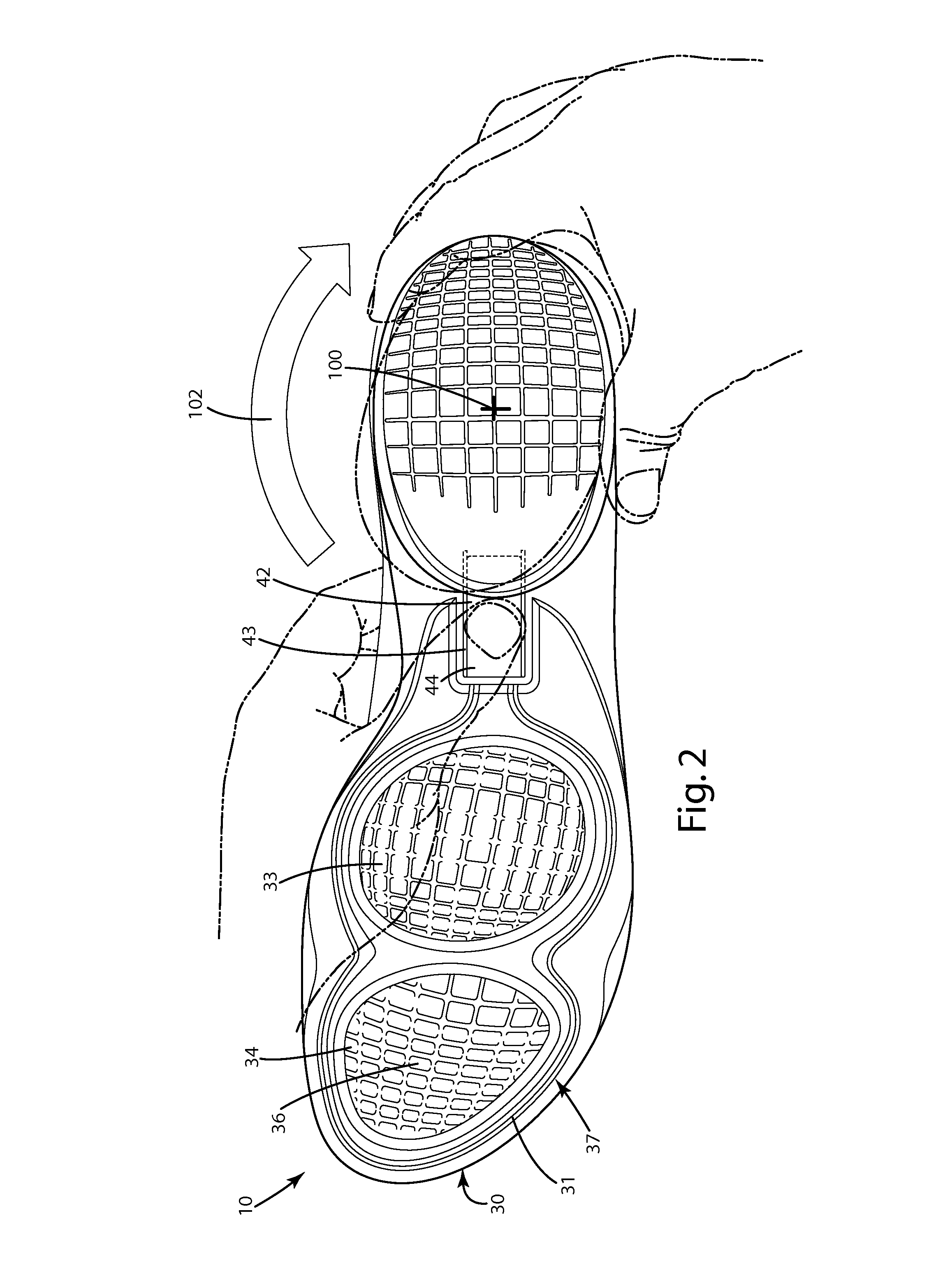

Adjustable footwear sole construction and related methods of use

a technology of sole construction and adjustable shoes, which is applied in the field of shoe sole construction, can solve the problems of over-complicated mechanism and other features of the heel element that provide the cushioning, difficult to operate the pins, and high cost and time consumption, and achieves simple and efficient, more stable performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first alternative embodiment

IV. First Alternative Embodiment

[0087]A first alternative embodiment of the footwear is illustrated in FIGS. 14-22 and generally designated 110. This footwear 110 and its corresponding sole 130 is similar to the embodiment described above with several exceptions. For example, the support element 140 and adjustment assembly 60 and certain components of the adjustable heel element 150 differ from the embodiment above.

[0088]As shown in FIGS. 14-16 and 22, the support plate 140 is configured to define a hole 141 within its upper surface 142 which generally faces the interior of the footwear 110 or upper. This hole can include a rim 143. Placed atop the rim and generally covering the hole is a support plate 144, which is generally configured in the same shape as the hole 141. The support plate can be generally rigid, inflexible and non-deflectable, and can cover the hole and make the upper surface 142 of the support plate 140 generally continuous and flat. The rigid plate 144 optionally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com