Preloaded triple roller entry guide

a technology of entry guide and triple roller, which is applied in the field of apparatus and methods of rolling steel with a triple roller entry guide, can solve the problems of affecting the quality of the triple guide, the inability to load the guide, and the inability to meet the requirements of the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

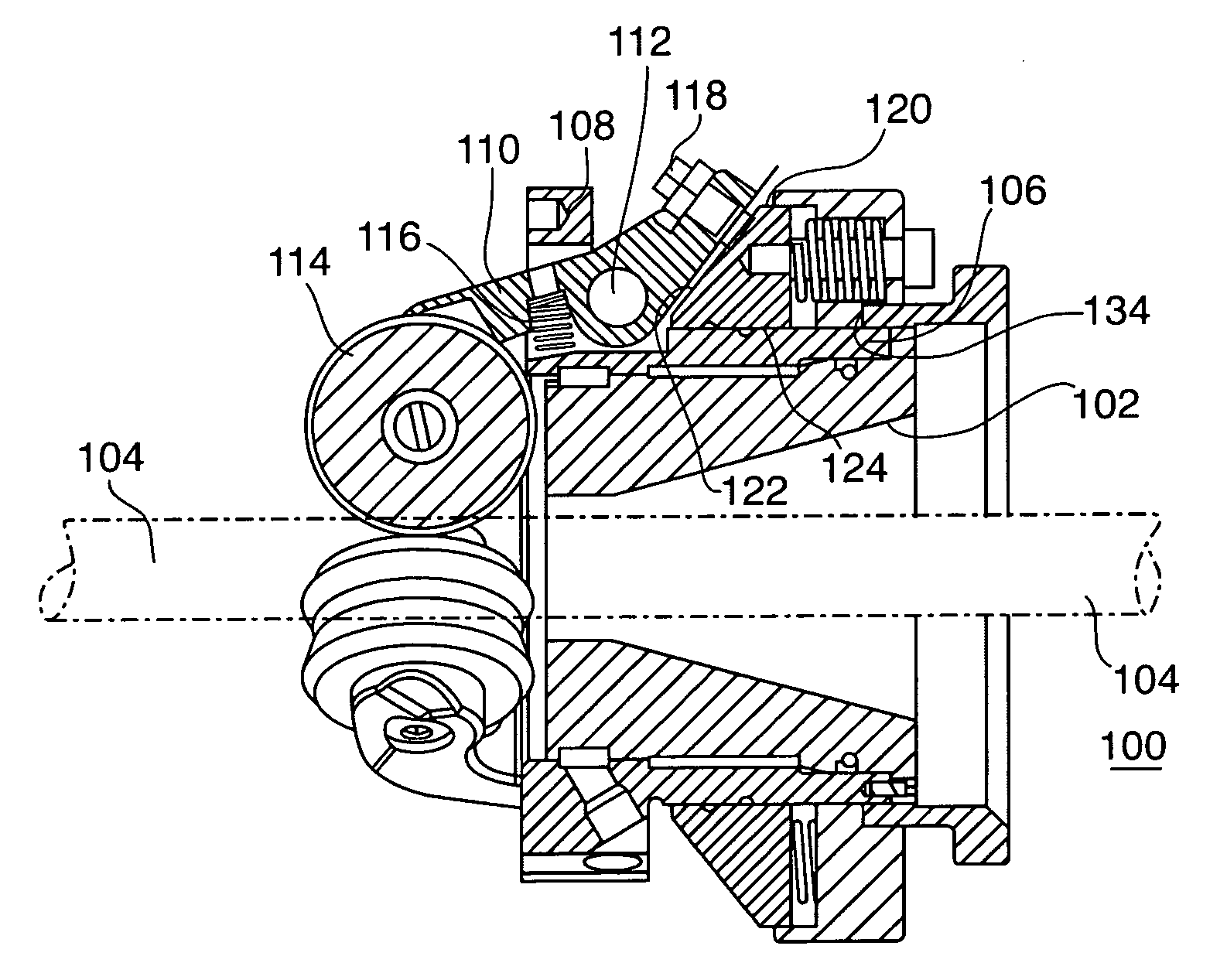

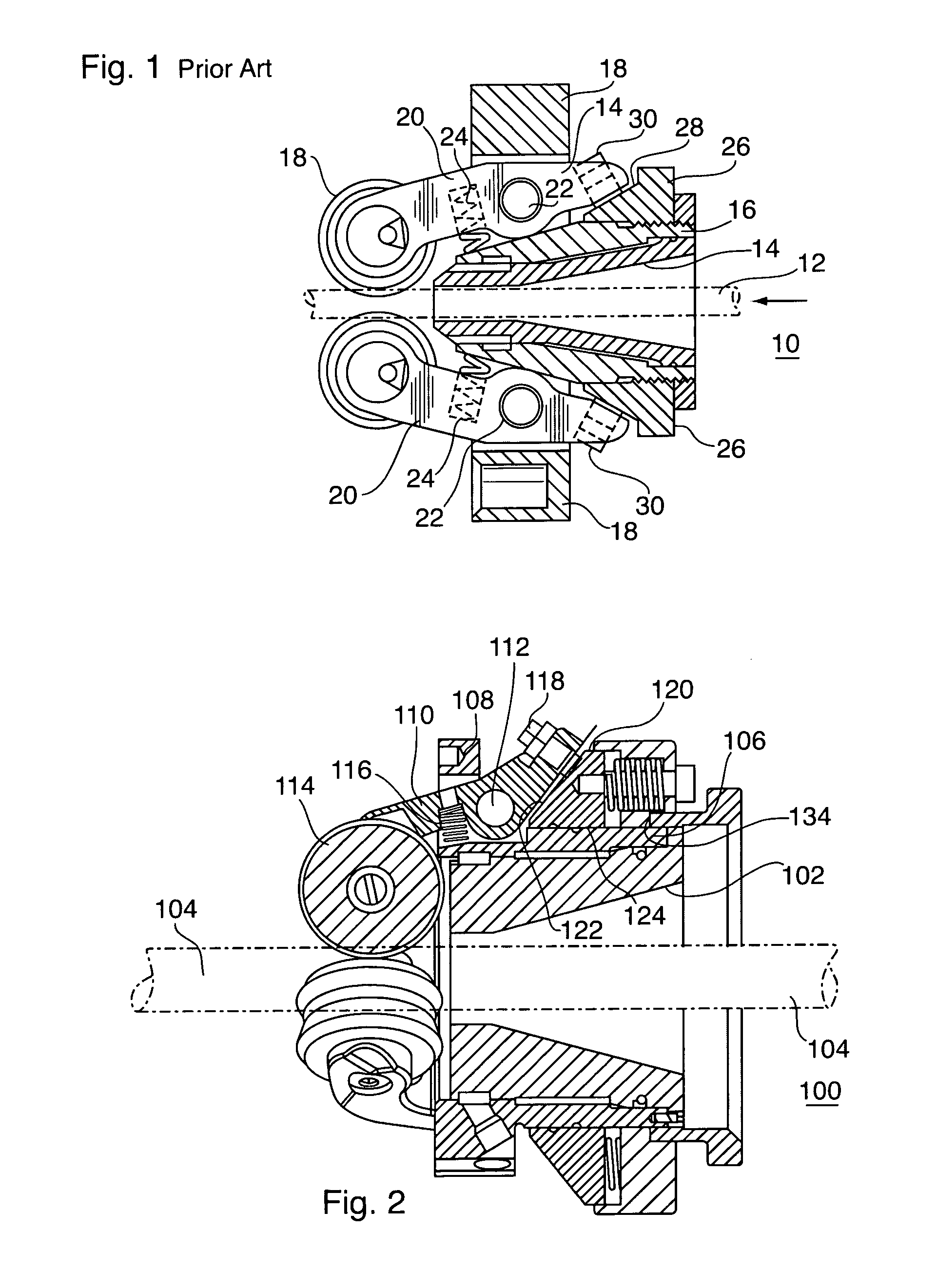

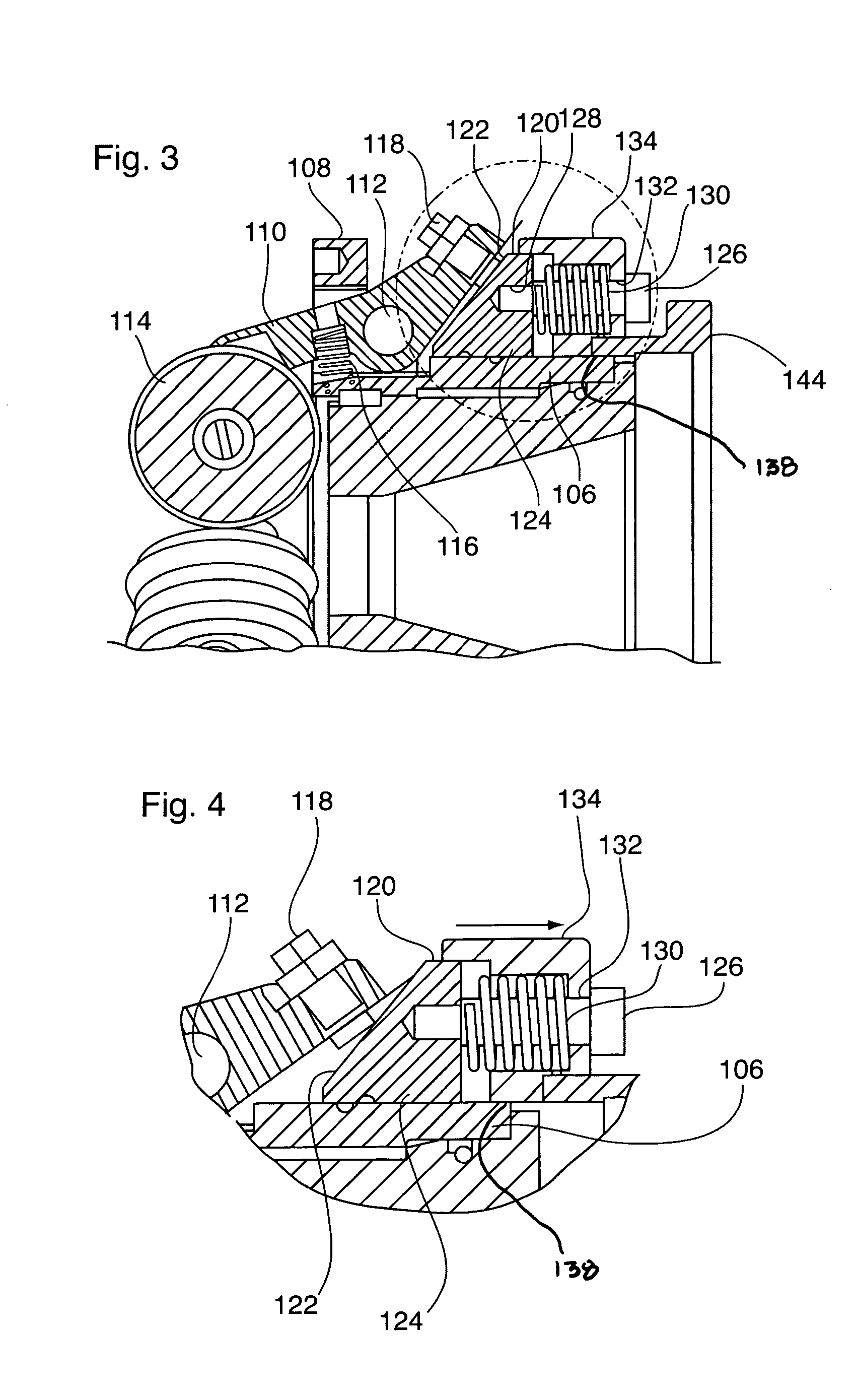

[0016]The principal of the standard triple jaw guide as shown in FIG. 1 is briefly described in the following passage. Reference may be had to applicant's prior patent referred to above for a complete explanation of the operation of the triple jaw guide. The triple jaw guide 10 as shown in FIG. 1 is shown having a work piece 12 passing there through from right to left. The work piece 12 must pass through a funnel shaped member 14 which is held in place by an intermediate member 16, which is part of stationary ring 18 on which jaws 20 are mounted.

[0017]Jaws 20 (of which two are shown) are mounted on pivots 22 which are permanently located in ring 18. Springs 24 assure that jaws 20 always present an opening which is a maximum for the passage of work product there through.

[0018]The adjustment of the opening of guide 10 is accomplished by the lateral movement of ring 26 which is mounted on the member 16 and moves to the left or right as determined by the direction of twist of the ring 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Force | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com