Apparatus for Dispensing Plastic Bags

a dispenser and plastic bag technology, applied in metal-working apparatus, domestic applications, thin material processing, etc., can solve the problems of long string of bags hanging from the roll, difficult for consumers to separate bags from the rolls, and inconvenient opening of the dispenser, so as to reduce the footprint of bags and dispensers, easy to separate from the rolls, and easy to open

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

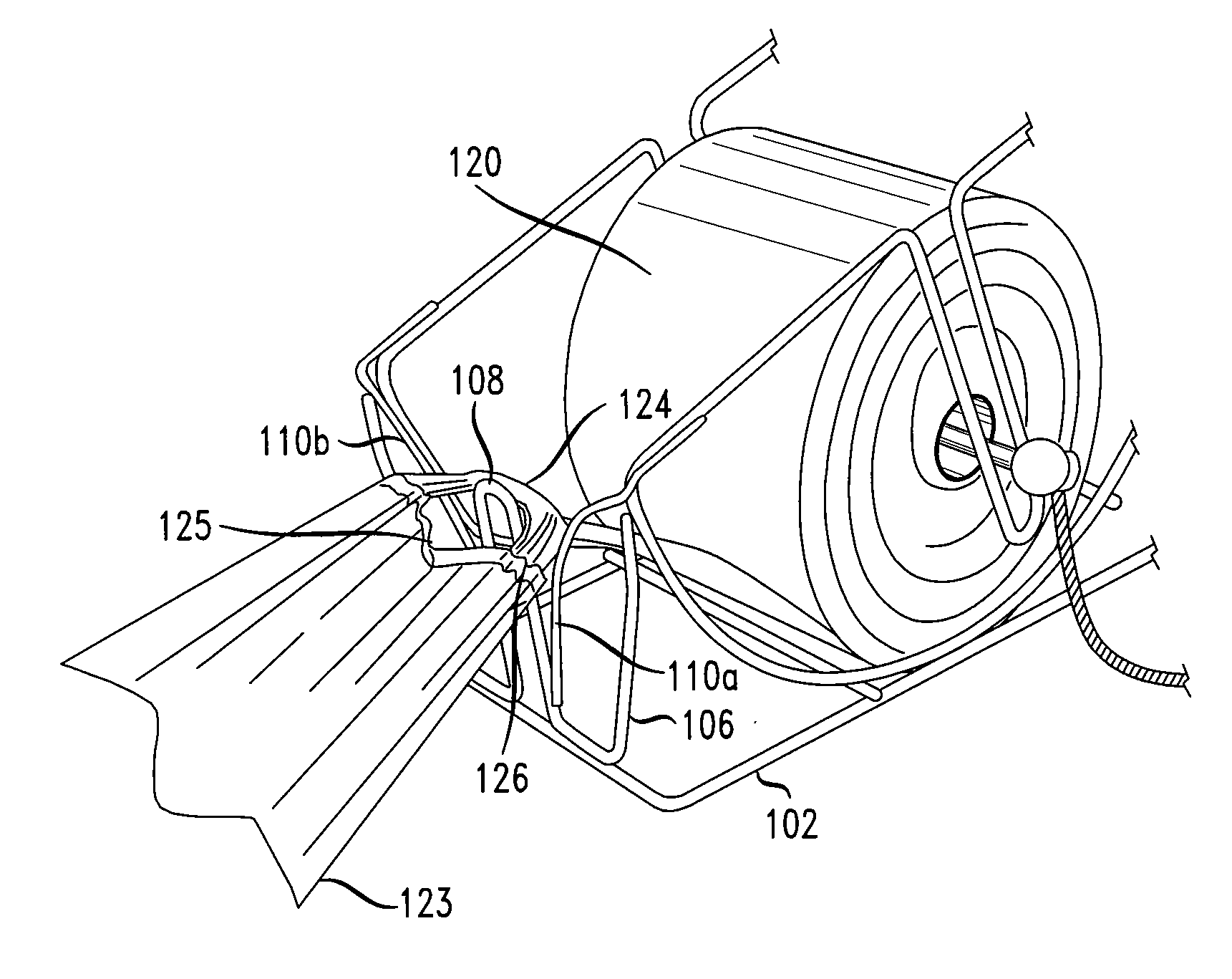

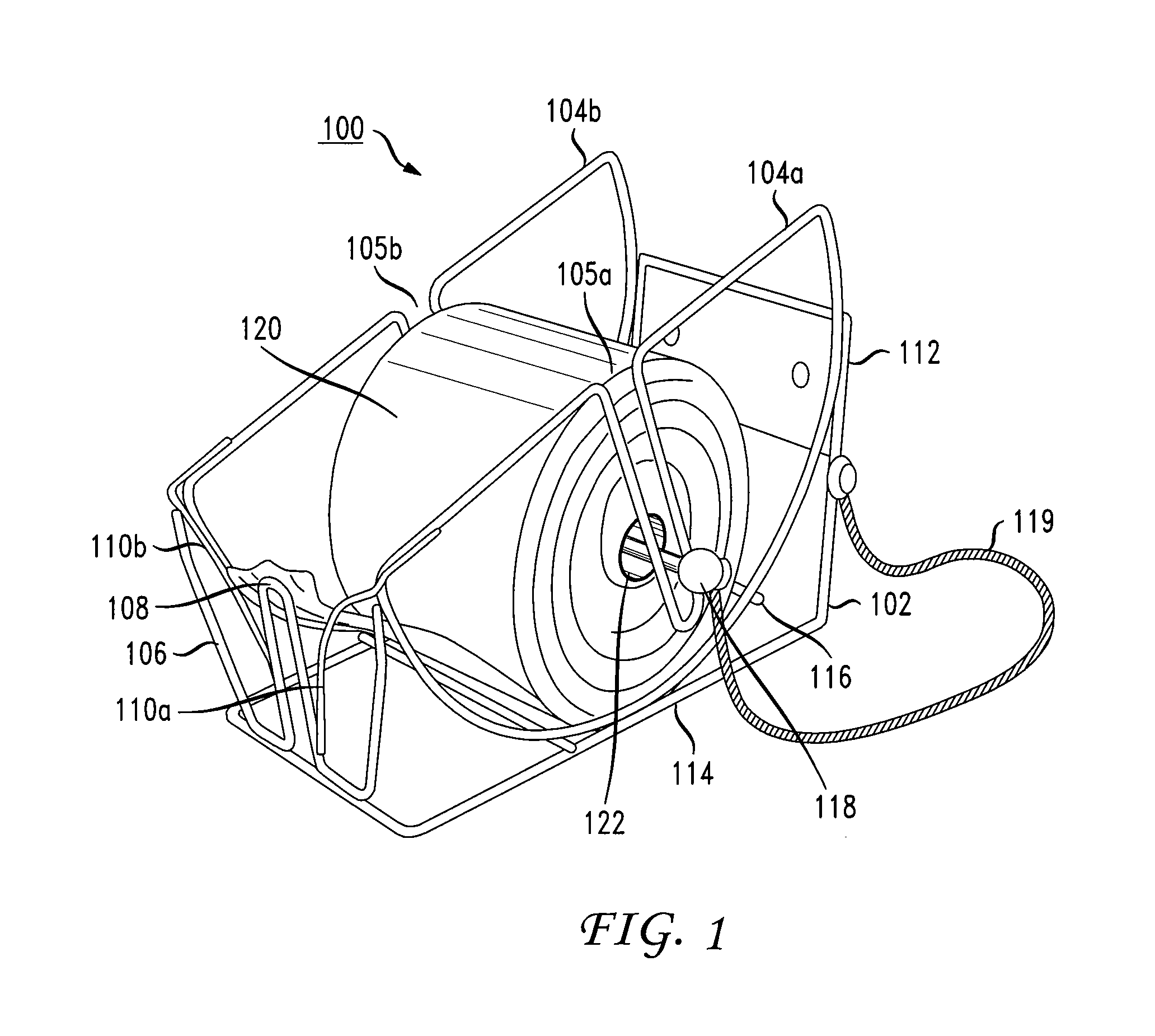

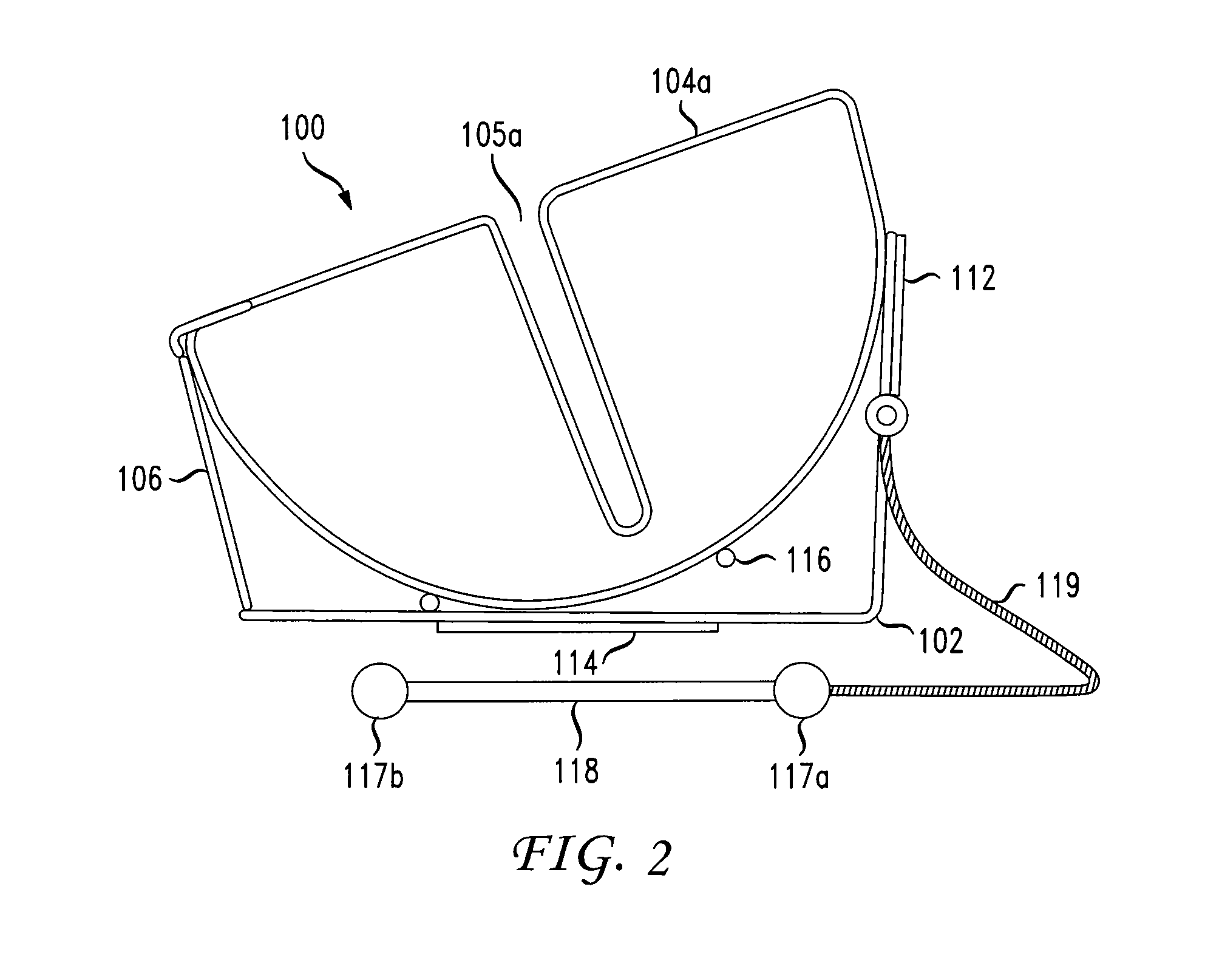

[0019]FIG. 1 is a perspective view of an apparatus for dispensing bags on a roll according to an embodiment of the present invention. As illustrated in FIG. 1, the apparatus includes a dispensing rack 100 capable of housing a roll of plastic bags 120. FIG. 2 is a side view showing the dispenser rack 100. FIG. 3 is a side view showing the roll of bags 120 and the dispenser rack 100. FIG. 4 is a side view showing the roll of bags seated within the dispenser rack.

[0020]As illustrated in FIGS. 1 and 2, the dispensing rack 100 includes a base 102 that is substantially “L” shaped, two semi-circular sides 104a and 104b attached to the base 102, and a front portion 106 attached to the base 102 and the sides 104a and 104b. The front portion 106 of the dispensing rack 100 includes a tongue 108, which may be integrally formed with the front portion 106 of the dispensing rack 100. The dispensing rack 100 also includes wedges 110a and 110b. The wedges 110a and 110b may be connected to the sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com