Laterally sliding roller ski

a roller ski and lateral sliding technology, applied in the field of roller skis, can solve the problems of difficult learning and execution, side cut and flex in the ski design, complex interactions between skis, etc., and achieve the effect of economic production and sales

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

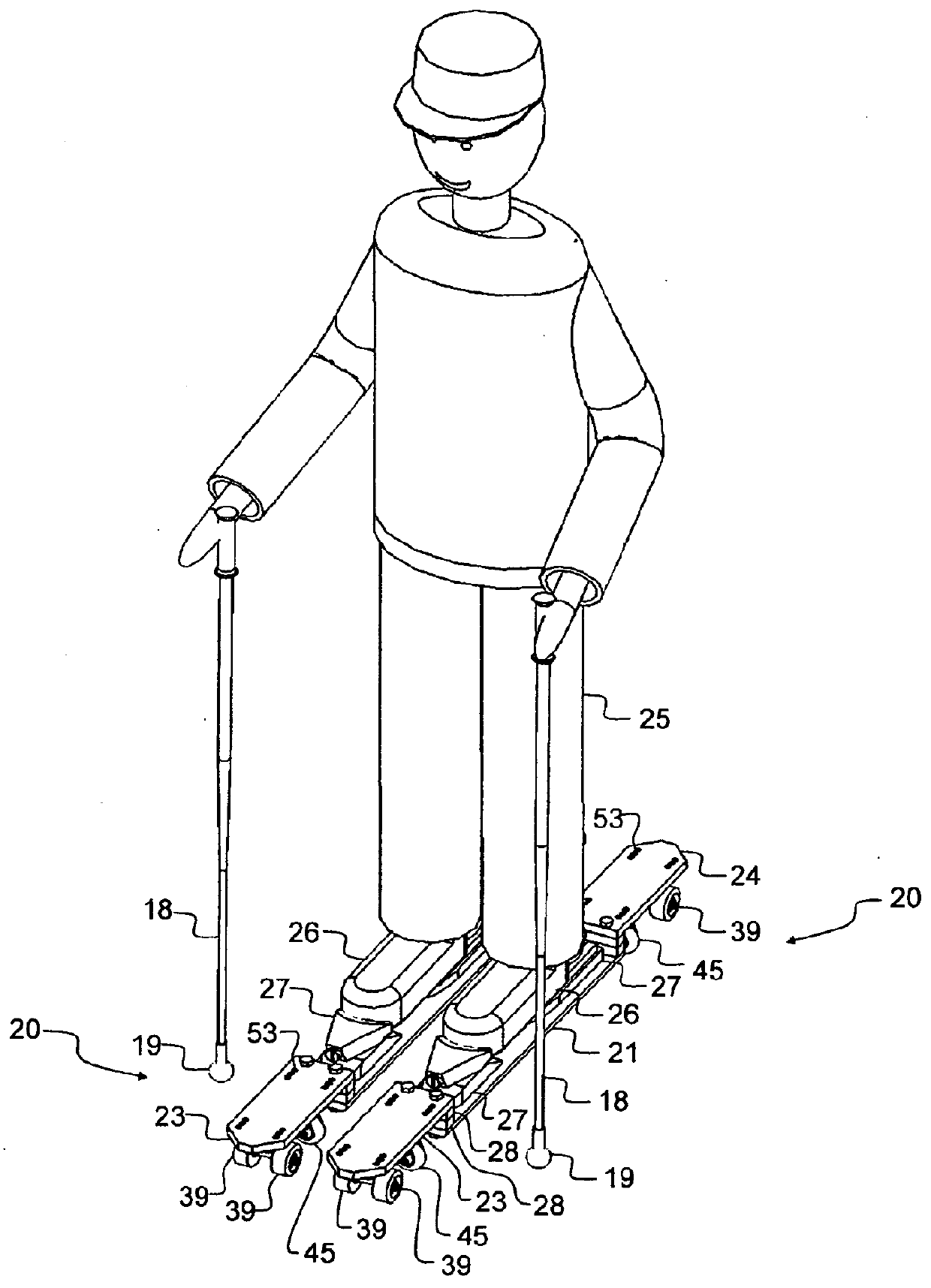

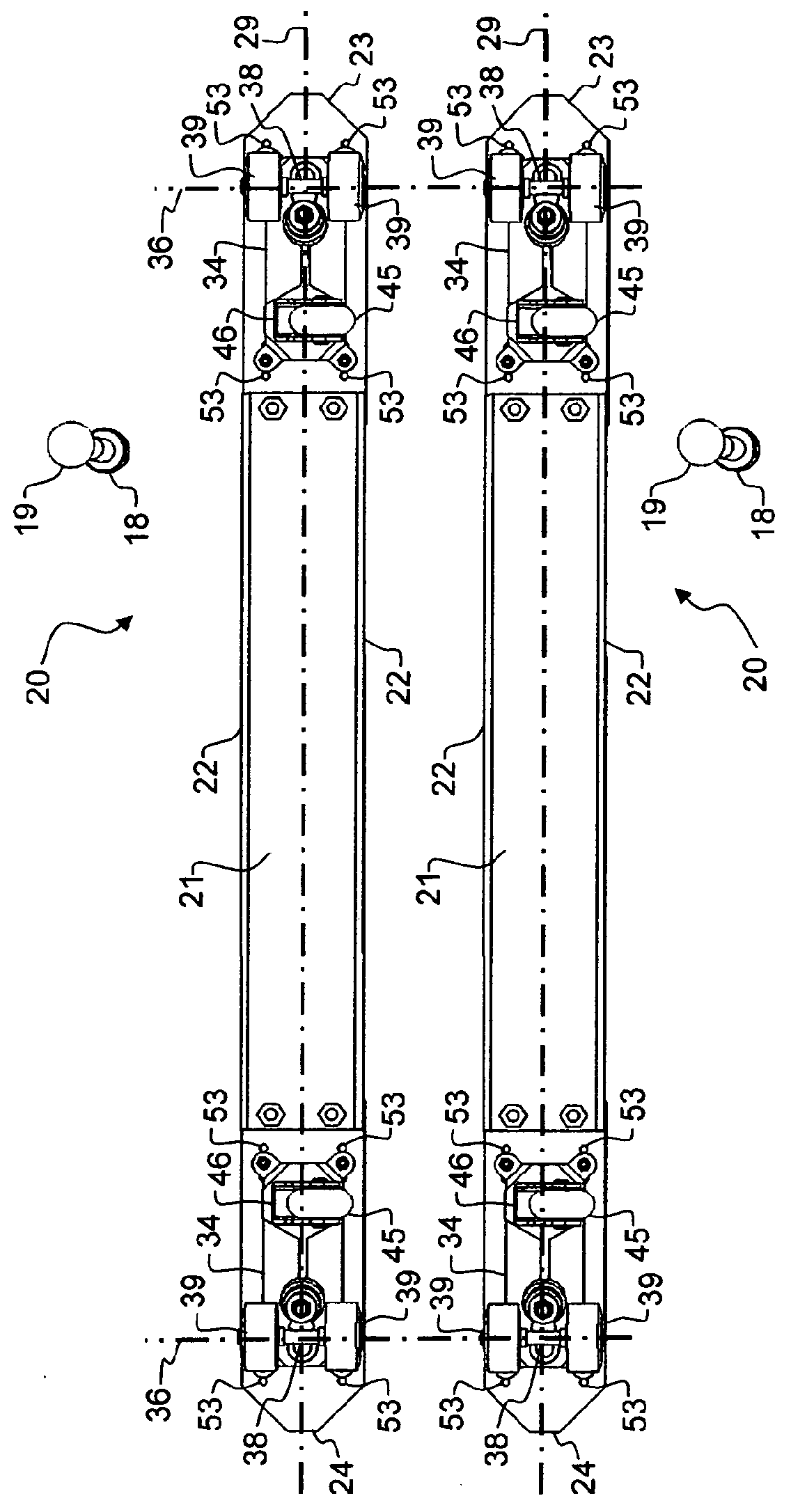

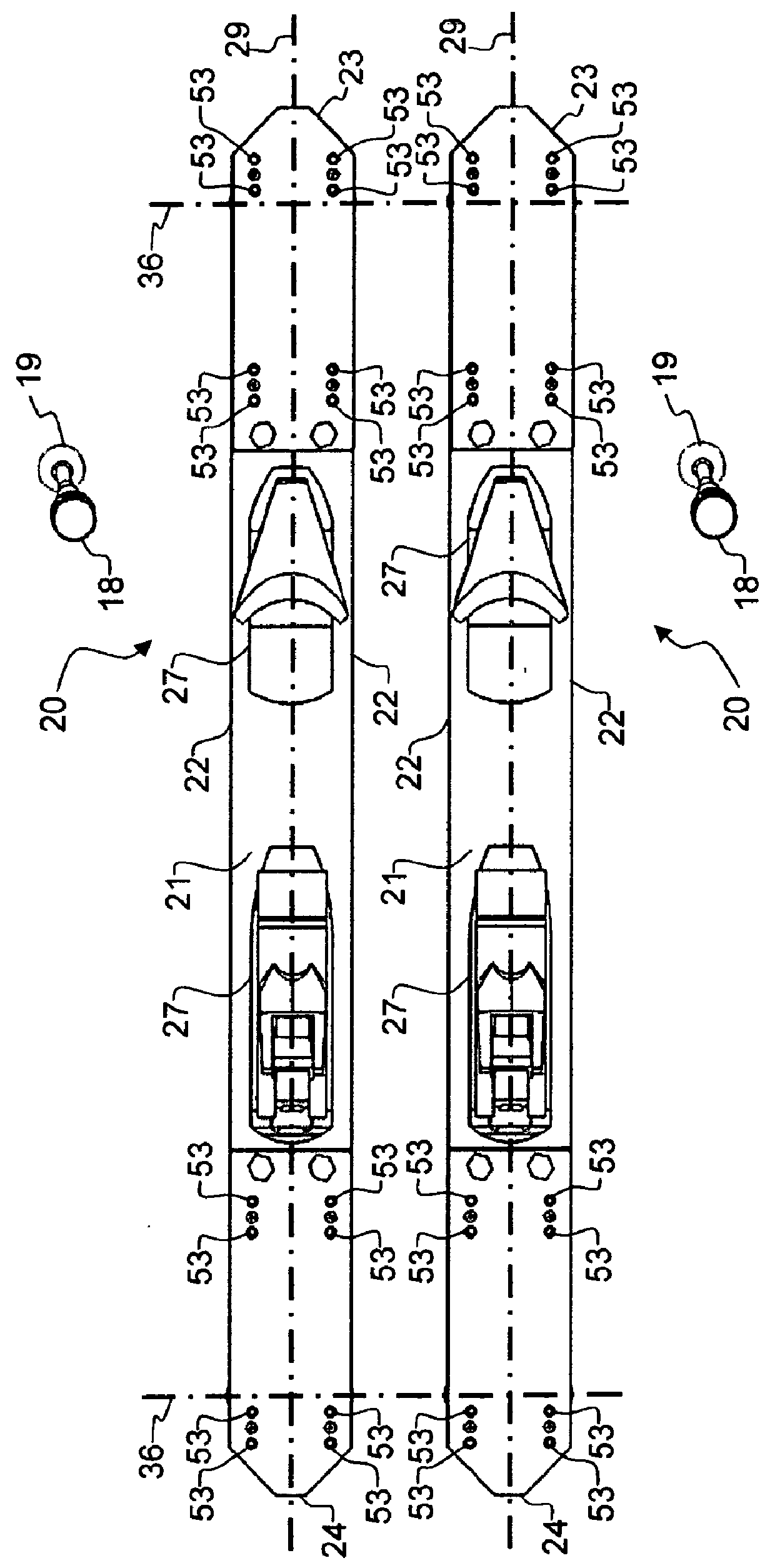

[0043]A typical embodiment of the present invention is shown in FIG. 1-4. A ski 20 has a center platform 21, two sides 22, a front tip 23, and a rear tail 24. If so desired, front tip 23 can be differ in shape from rear tail 24. Sides 22 are roughly identical to each other. Ski 20 can be wider and longer than a normal roller ski. Typical roller ski platforms measure between two to four inches wide and nineteen to twenty six inches long. Ski 20 can measure between three to eight inches wide and between thirty six to sixty inches long, depending on skier's 25 size, weight and specific application. As will be shown later, the sizing affects the trade off between maneuverability and stability.

[0044]A skier 25 positions them self on the center platform 21 in a stance similar to that used for snow skiing or conventional roller skiing, with both feet 27 roughly parallel to a longitudinal center line 29. This stance allows skier 25 to easily shift their weight from left to right or from toe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com