Apparatus and method for enhanced heat transfer

a technology of enhanced heat transfer and apparatus, applied in the field of thermal management technology, can solve the problems of incompatibility of two-phase heat transfer systems with microelectronic packages, limitations to the current state of two-phase cooling, and phase change that greatly increases the heat flux from the heated surface, so as to achieve the effect of dissipating more energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

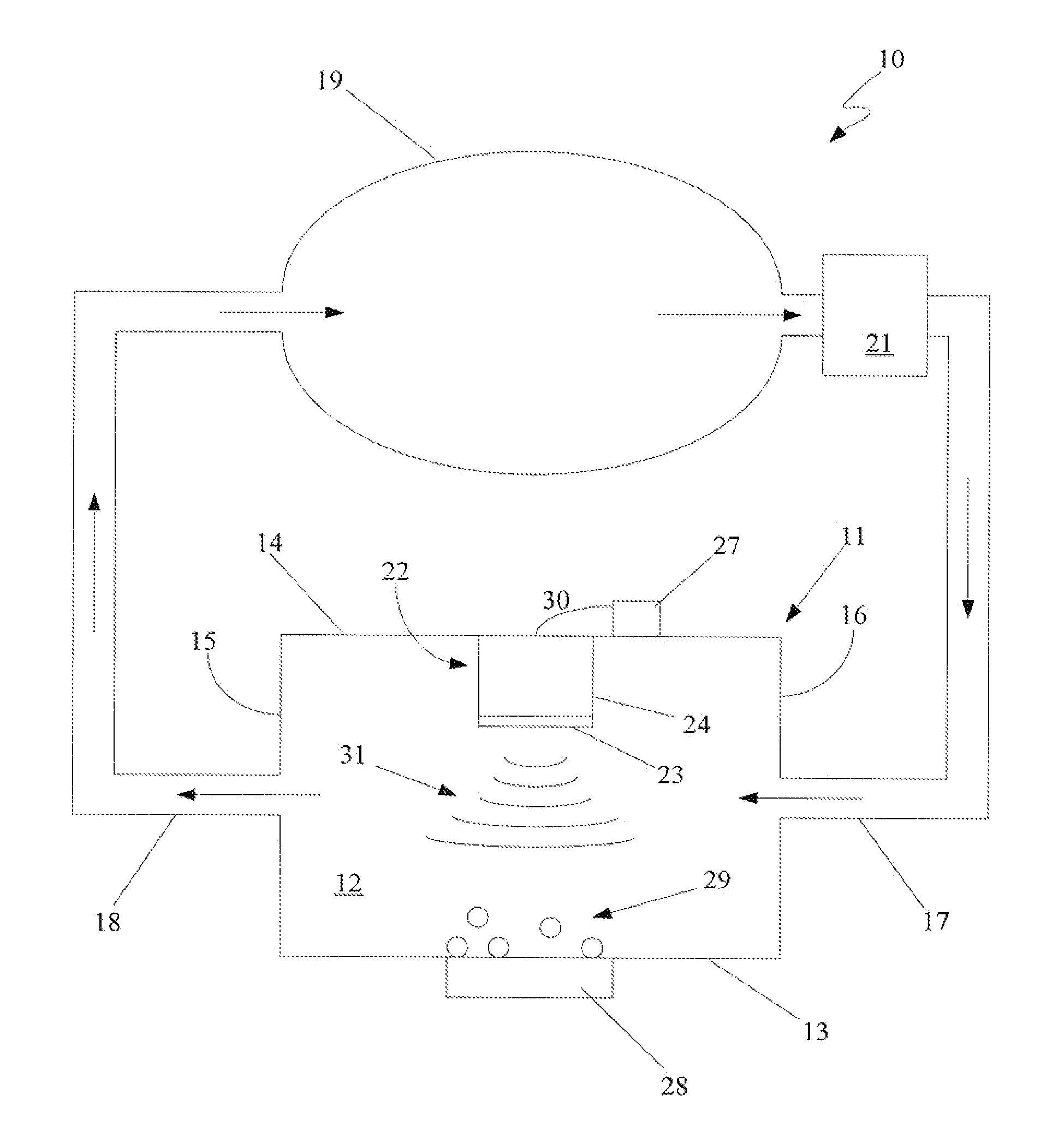

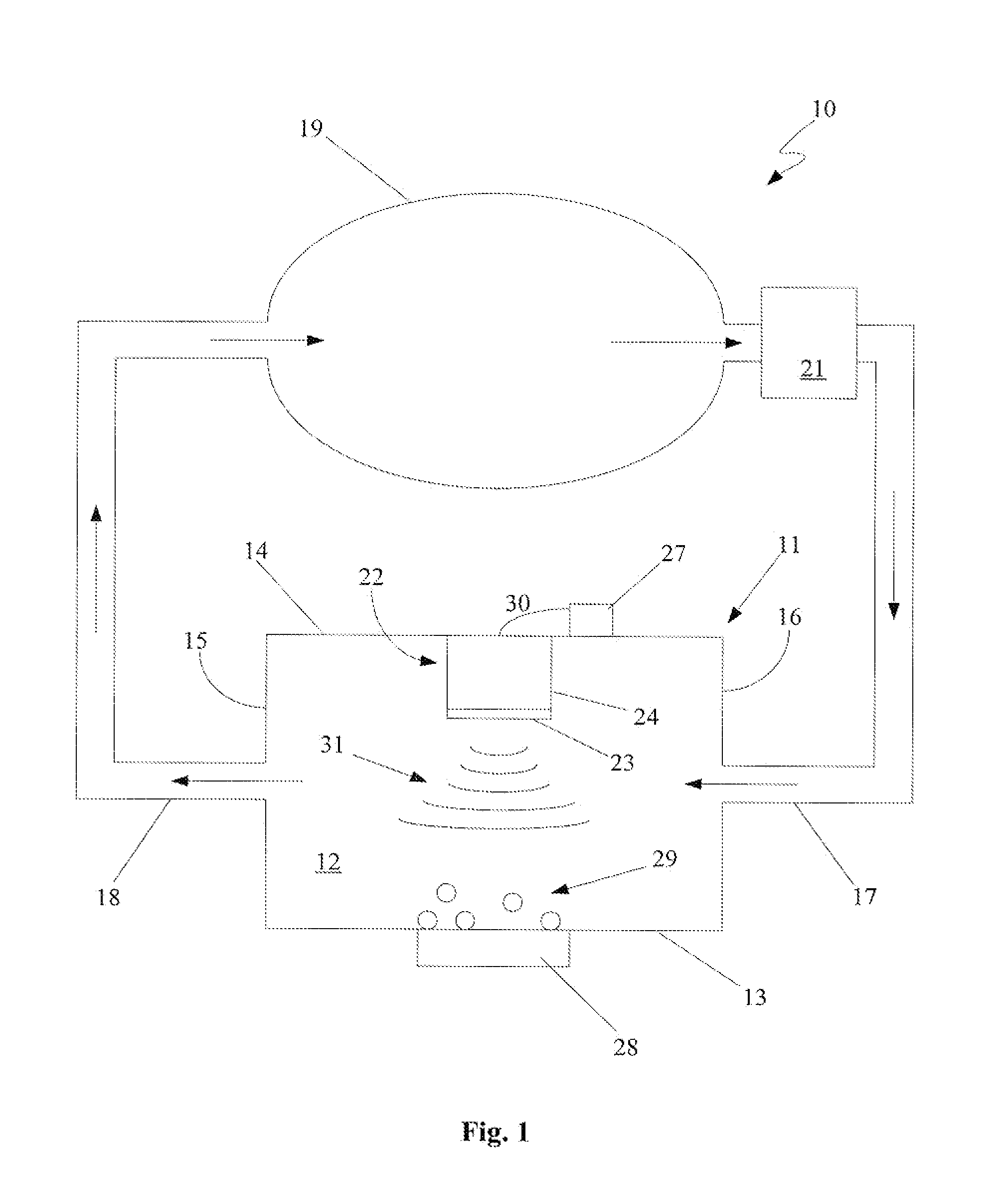

embodiment 10

[0025]The chamber 11 could be constructed of any suitable material. Generally, the material used for the chamber 11 will depend to some degree on the particular fluid 12 in the chamber 11 and on the particular heat transfer characteristics desired. The preferred material from which the chamber 11 is to be constructed is a light-weight metallic material from which the chamber 11 can be easily and inexpensively manufactured. For example, the material for the chamber 11 of the present embodiment 10 is aluminum.

[0026]In the present embodiment 10, the entire chamber 11 is constructed from an aluminum material. However, in an alternative embodiment, the chamber 11 is manufactured from more than one material. In other words, different parts of the chamber 11 are manufactured from different materials. Such a configuration minimizes heat transfer to certain parts of the chamber 11, while maximizing heat transfer to other parts of the chamber 11.

[0027]More specifically, in this alternative em...

embodiment 50

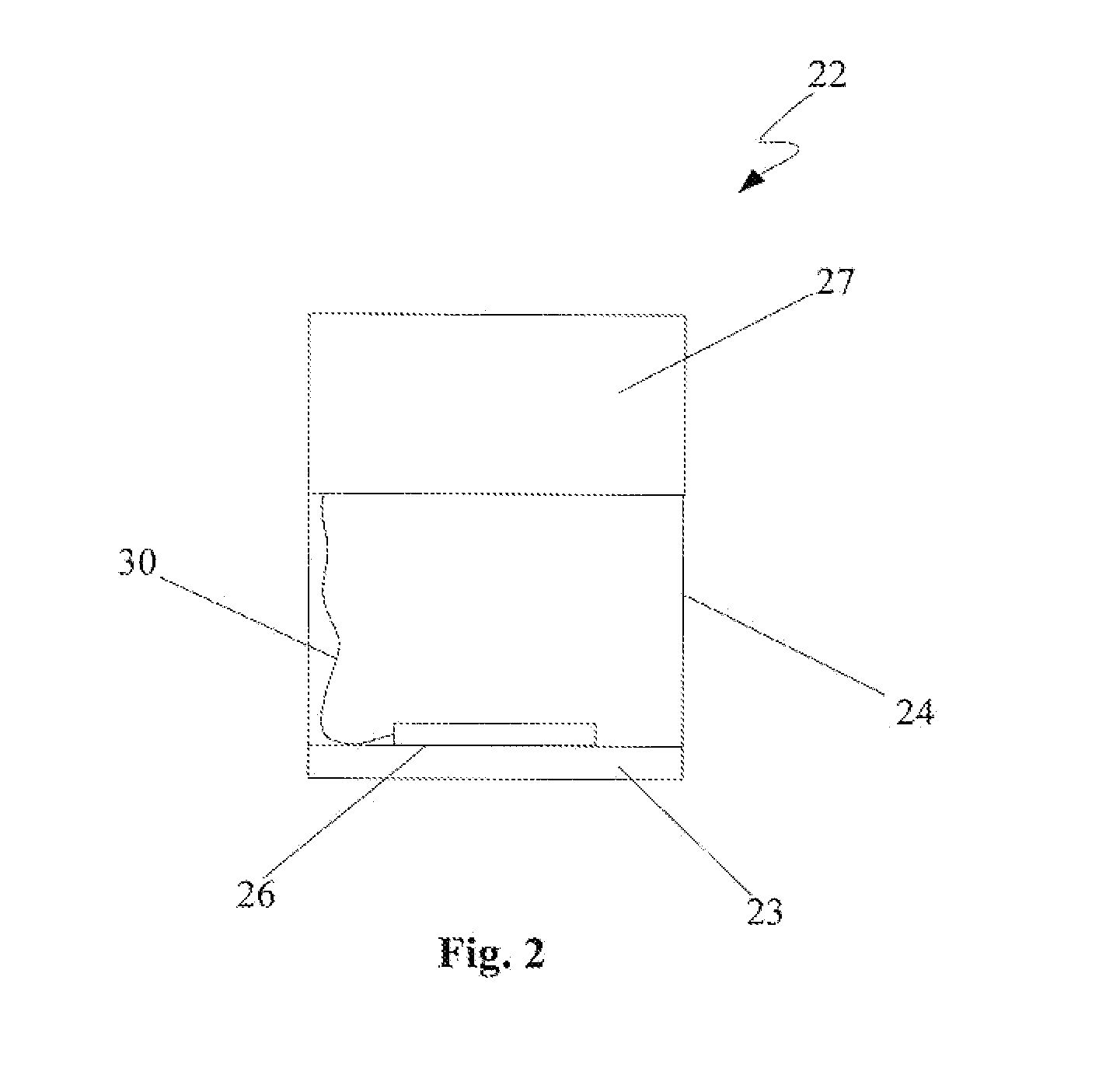

[0056]An alternative embodiment of a VIBE apparatus 60 is depicted in FIG. 6. This embodiment 60 is very similar to the previous embodiment 50. However, small synthetic jet actuators 61, 62 have been placed within the chamber 11. Synthetic jet actuators, generally, are described in detail in U.S. Pat. No. 5,758,853 to Glezer et al., entitled “Synthetic Jet Actuators and Applications Thereof,” which is incorporated herein by reference. Basically, the synthetic jet actuators 61, 62 create jets 63, 64 of fluid without net mass injection into the chamber 11. The fluidic jets 63, 64 agitate the fluid 12 in the chamber 11 resulting in more effective heat transfer.

[0057]Other alternative embodiments of the VIBE device involve modifications of the actuator 22. One of these alternative embodiments involves using more than one actuator 22 in the chamber 11. An array of actuators is positioned along the upper wall 14 of the chamber 11. In another alternative embodiment, the actuator 22 compris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com