Sports footwear

a technology of sports footwear and fixing elements, applied in the field of footwear, can solve the problems of user-specific characteristics, reducing the useful life of the boot, and wear of the fixing element, and achieve the effects of extending the useful life, ensuring safety, and satisfying the steering precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

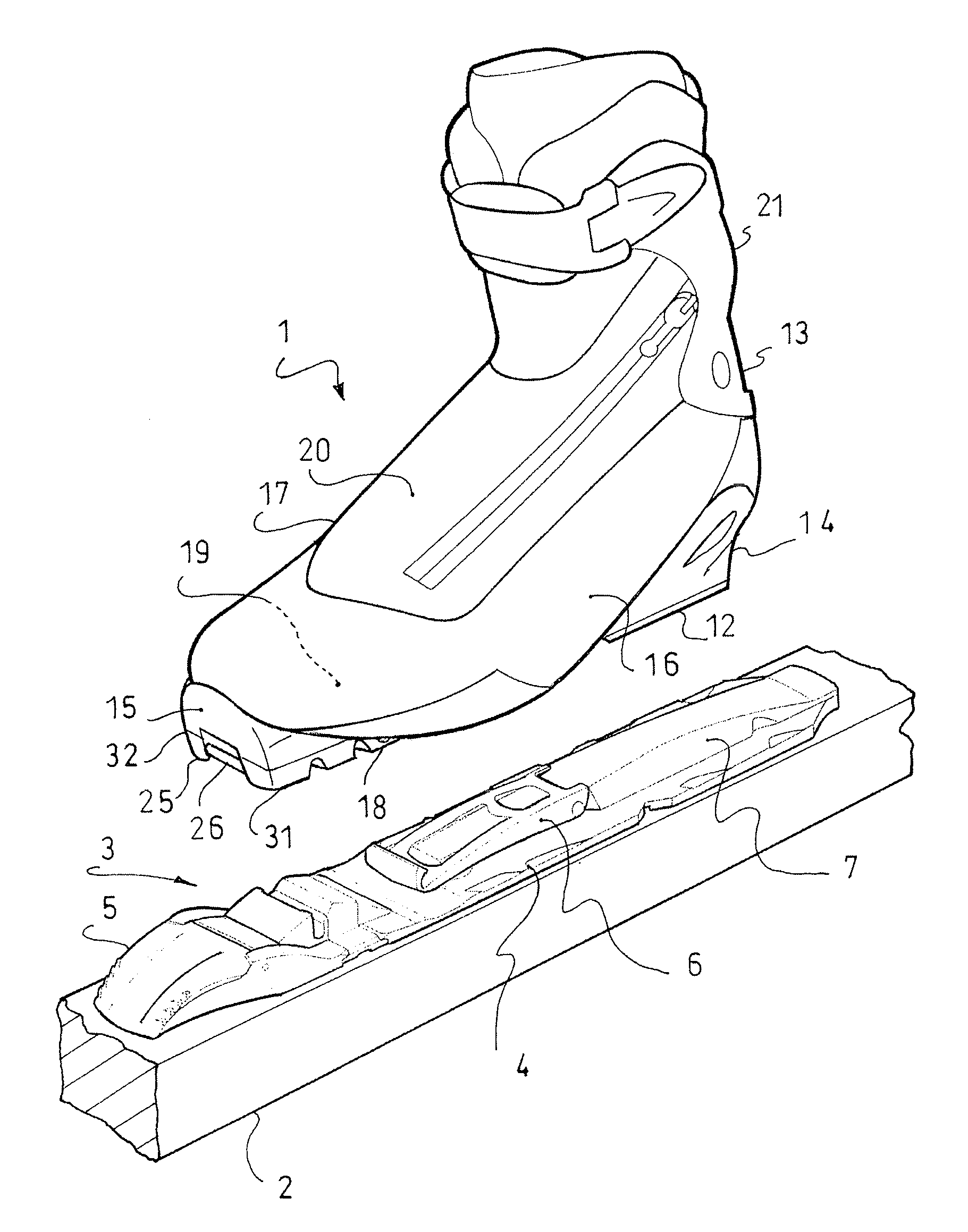

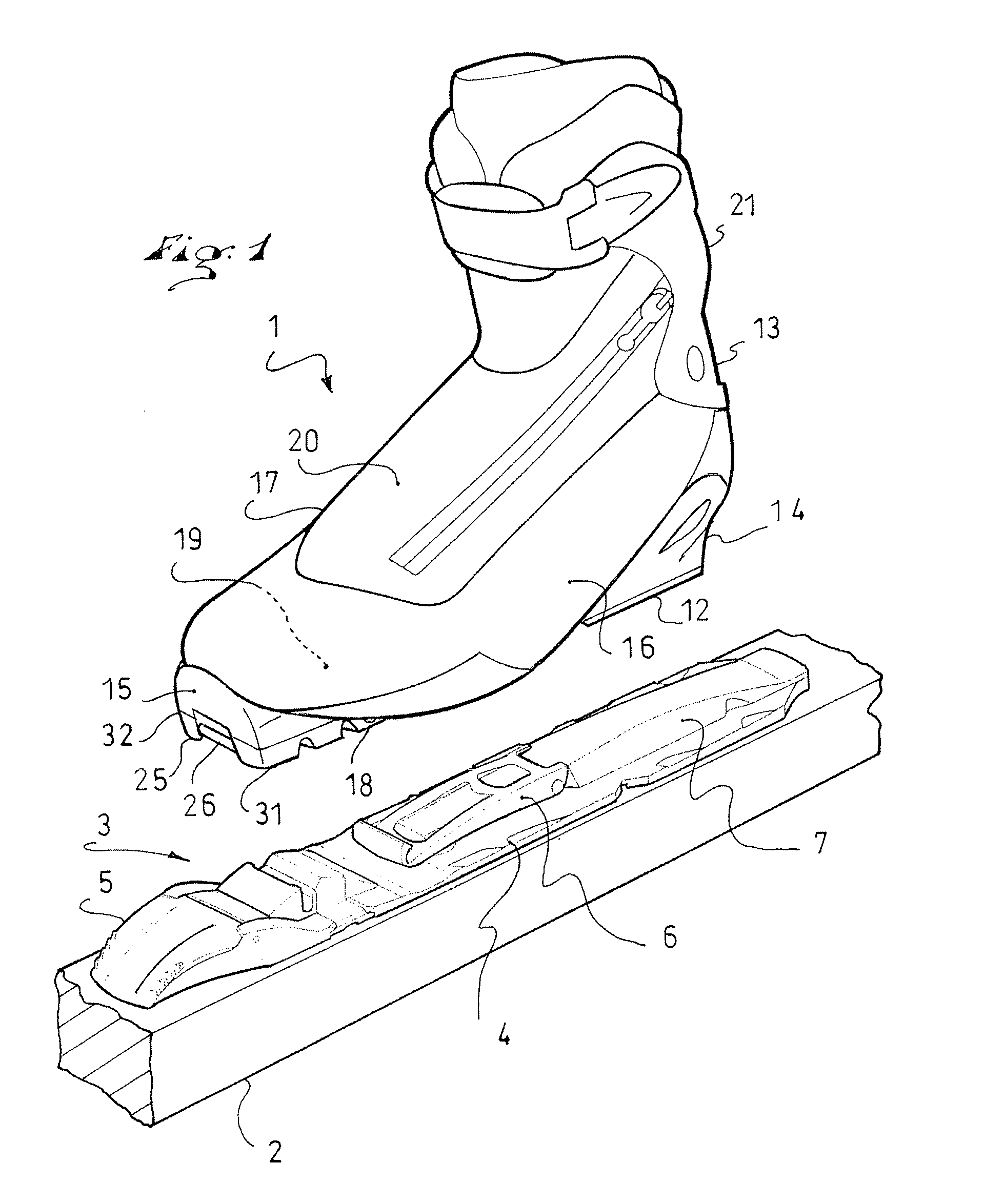

[0038]The first embodiment is illustrated with reference to FIGS. 1 to 4. FIG. 1 shows an assembly that includes a boot 1, a ski 2, and a device 3 for retaining the boot on the ski.

[0039]Conventionally, the retaining device 3 includes a baseplate 4, which carries a reversible locking mechanism 5, an elastic return mechanism 6, and a longitudinal guiding rib 7. For example, it is possible to affix the locking mechanism 5, the return mechanism 6, and the guiding rib 7 to the baseplate 4, to make the retaining device 3 cohesive. The retaining device 3 and the ski 2 will not be further described, as they are well known to one of ordinary skill in the art. The retaining device can be any of various types, such as that disclosed in U.S. Pat. No. 6,017,050, the disclosure of which is hereby incorporated by reference thereto in its entirety.

[0040]The boot 1 includes an outer sole assembly 12 and an upper 13. The outer sole assembly 12 can include one, two, or more portions. The boot 1 exten...

second embodiment

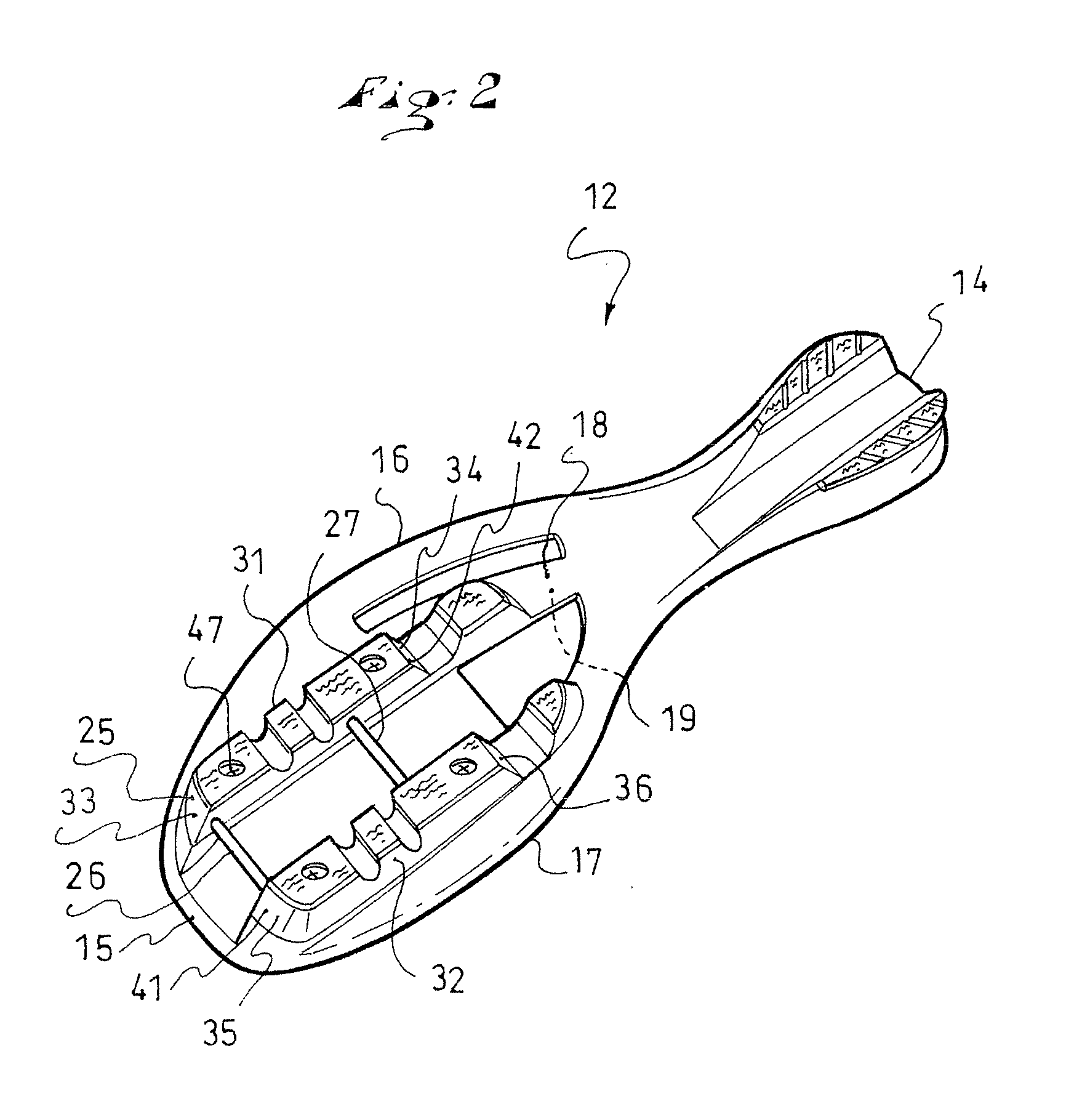

[0060]In this regard, a second embodiment, according to FIGS. 5 to 7, has an outer sole assembly 12, with its rear end 14 and front end 15, its lateral side 16 and medial 17 sides, and its free 18 and connection 19 surfaces. There is also a fastening element 25, with its first 26 and second 27 wires, as well as its first 31 and second 32 longitudinal bars.

[0061]The second embodiment is specific to the manner in which the fastening element 25 is positioned on the outer sole assembly 12. The boot 1 in this case includes a mechanism for positioning the fastening element 25 on the outer sole assembly 12, via a discrete adjustment in at least two positions, viz., a first position for which a first end 41 of the fastening element 25 is located at a first distance from the front end 15 of the boot, and a second position for which the first end 41 of the fastening element 25 is located at a second distance from the front end 15 of the boot. This configuration allows the fastening element 25...

third embodiment

[0065]the invention is illustrated with reference to FIGS. 8 to 13. This embodiment also has an outer sole assembly 12, with its rear 14 and front 15 ends, its lateral 16 and medial 17 sides, and its free 18 and connection 19 surfaces. There is also a fastening element 25, with its first 26 and second 27 wires, as well as its first 31 and second 32 longitudinal bars.

[0066]The third embodiment is also specific to the manner in which the fastening element 25 is positioned on the outer sole assembly 12. The boot 1 in this case includes a mechanism for positioning the fastening element 25 on the outer sole assembly 12, via a continuous adjustment over a nominal range, the displacement of the fastening element 25 relative to the outer sole assembly 12 occurring longitudinally. This arrangement increases the possibilities of adjustment of the position of the fastening element 25. The adjustment is selectively carried out to move the fastening element toward or, conversely, away from the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com