Accumulator for refrigeration cycle system

a technology of accumulator and refrigeration cycle, which is applied in the field of refrigerating cycle system, can solve the problems of high cost and complicated construction of known accumulator, and achieve the effect of high cost and complicated construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

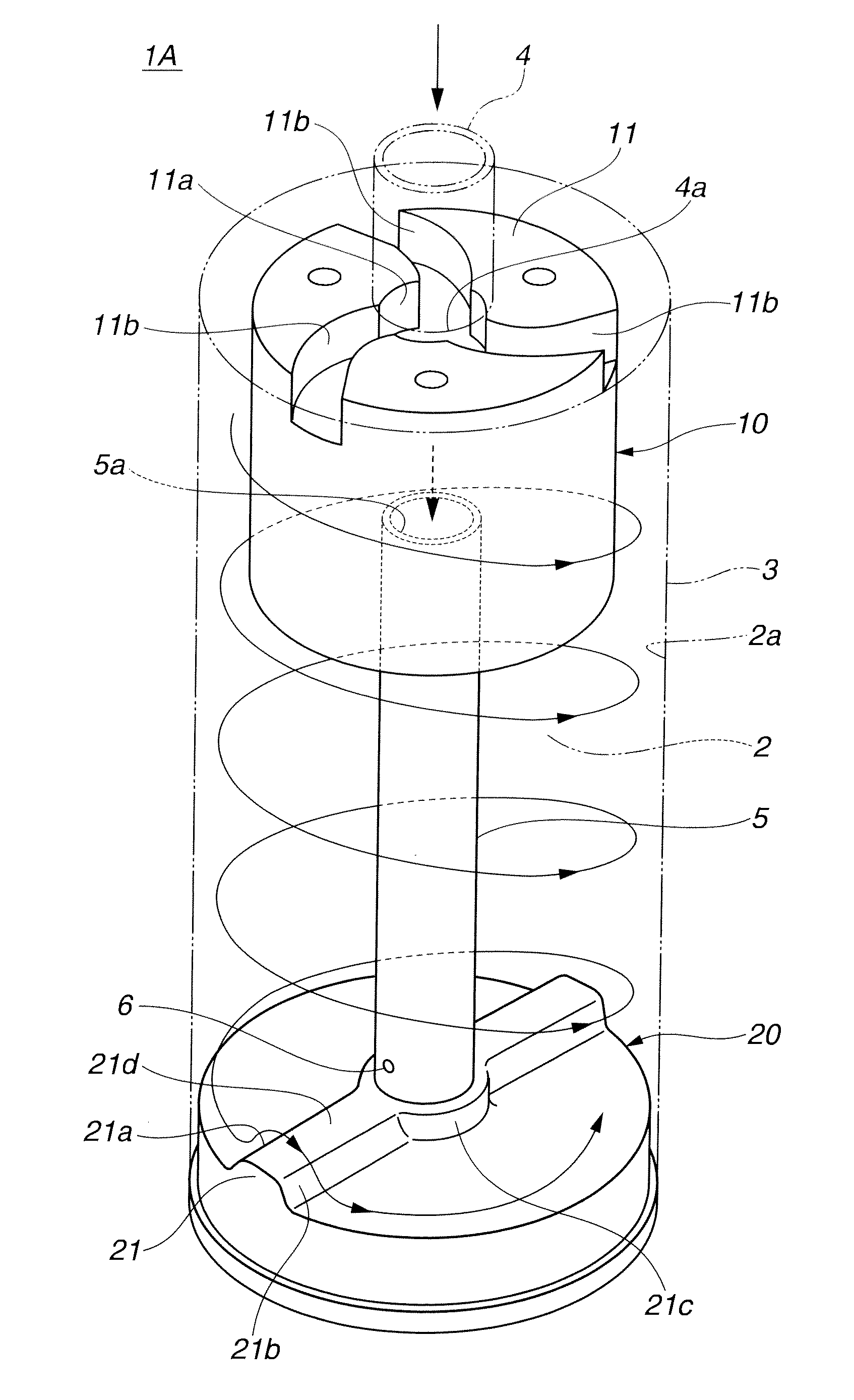

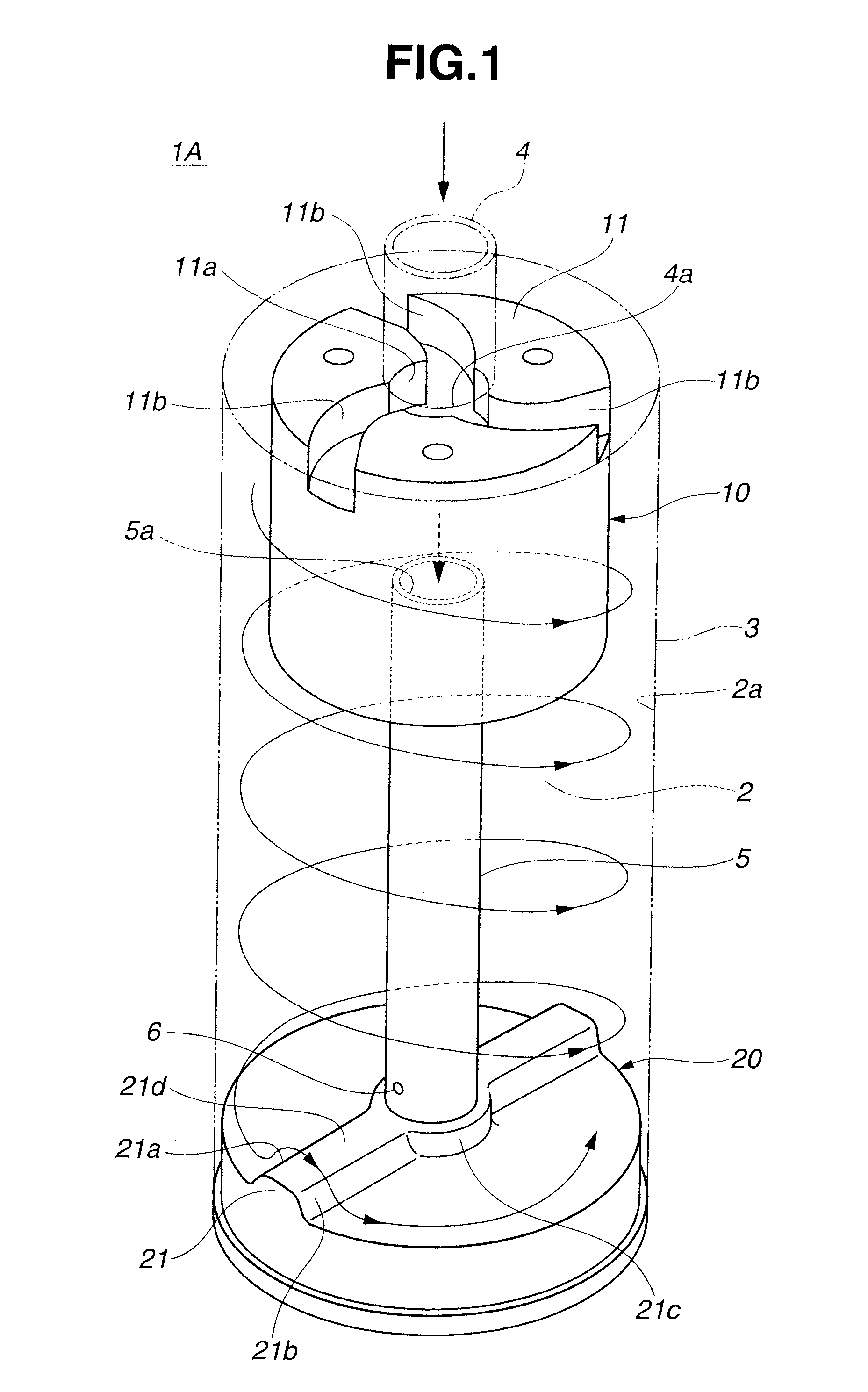

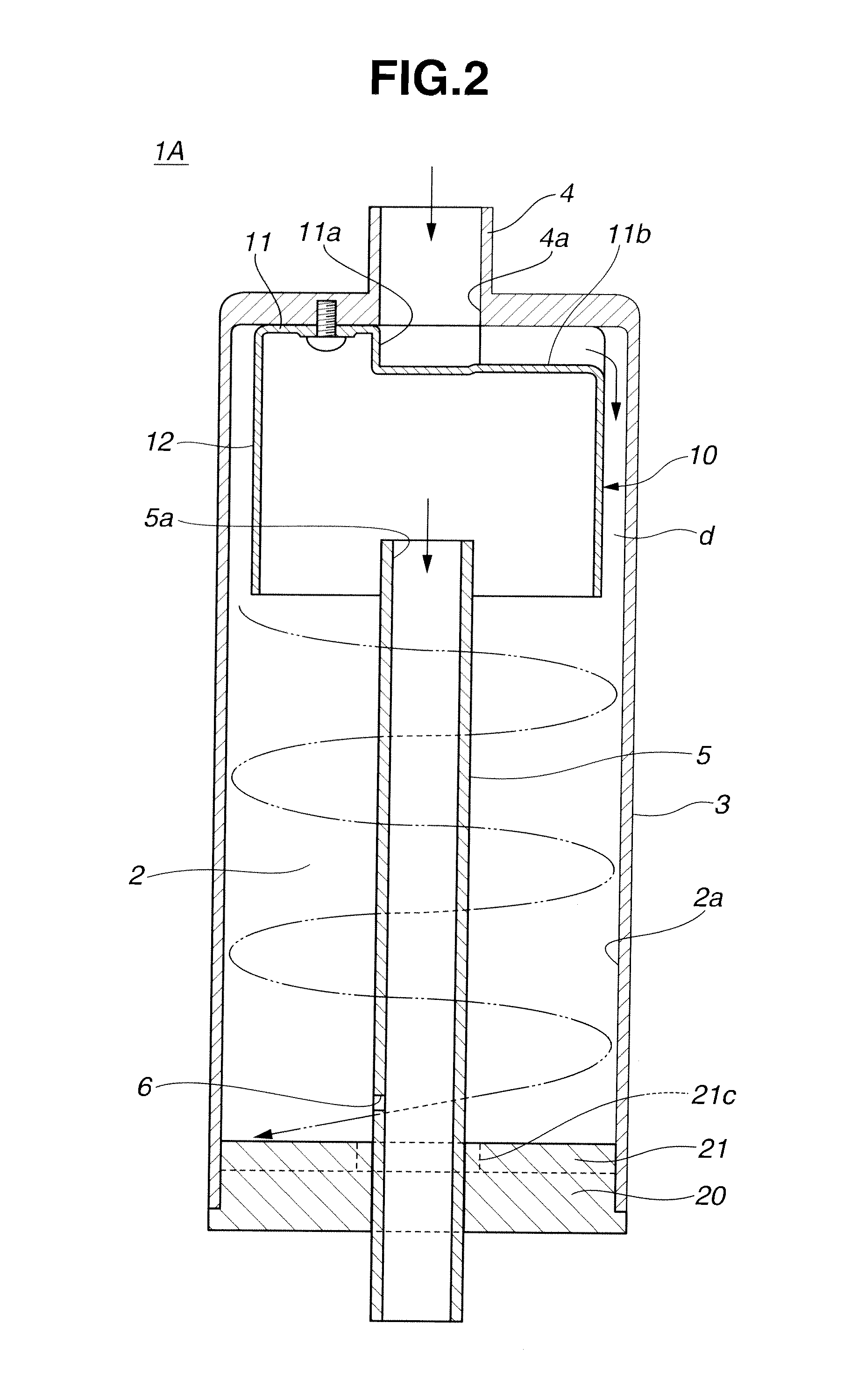

[0030]Referring to FIGS. 1 to 4, there is shown an accumulator 1A is of a first embodiment of the present invention for a refrigeration cycle system.

[0031]Like the above-mentioned known accumulator 50 of FIG. 8, the accumulator 1A of the first embodiment is arranged to stand upright when in use.

[0032]As is well shown in FIGS. 1 and 2, the accumulator 1A comprises a cylindrical case 3 that has a cylindrical liquid accumulating chamber 2 formed therein, a refrigerant inlet pipe 4 through which refrigerant is led into the liquid accumulating chamber 2 from an evaporator (not shown), a refrigerant outlet pipe 5 through which the refrigerant is discharged from the liquid accumulating chamber 2 to the outside (viz., compressor), a flow guide device 10 which provides the refrigerant from the refrigerant inlet pipe 4 with a whirling movement and an interference ridge portion 21 which provides the whirled flow of refrigerant from the flow guide device 10 with up-and-down movement (or stirs t...

second embodiment

[0058]Referring to FIGS. 5 to 7, there is shown an accumulator 1B of a second embodiment of the present invention for a refrigeration cycle system.

[0059]The accumulator 1B of the second embodiment is arranged to stand upright when in use, like in such a posture as shown in FIGS. 6 and 7.

[0060]As will be understood from FIG. 5 which is a horizontally sectrional view of the accumulator 1B, the accumulator 1B comprises a rectangular case 3 that has a rectangular liquid accumulating chamber 2 formed therein, first and second partition walls 30a and 30b that are alternately arranged in the chamber 2 to define therein first, second and third flow passages 2a, 2b and 2c that are connected in series in zigzag manner, a refrigerant inlet pipe 4 through which refrigerant is led into an upstream part of the first flow passage 2a, a refrigerant outlet pipe 5 through which the refrigerant is discharged from a downstream part of the third flow passage 2c to the outside, and a plurality of flow gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com