Method and apparatus for the mitigation of explosively formed projectiles

a technology mitigation methods, applied in the field of armor, can solve the problems of wreaking havoc, many casualties, and tremendous loss of strategic assets, and achieve the effect of reducing the effects of explosively formed projectiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

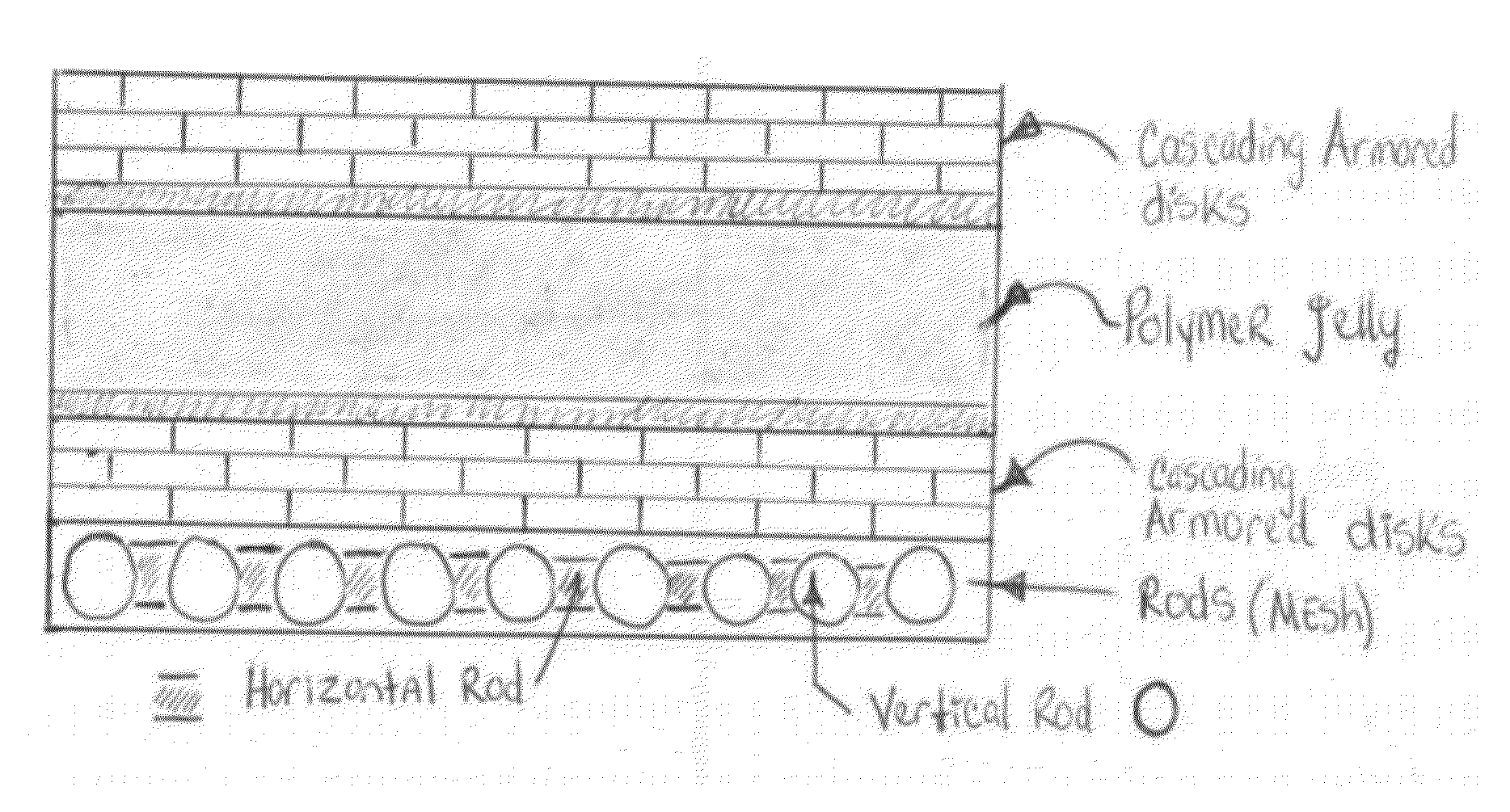

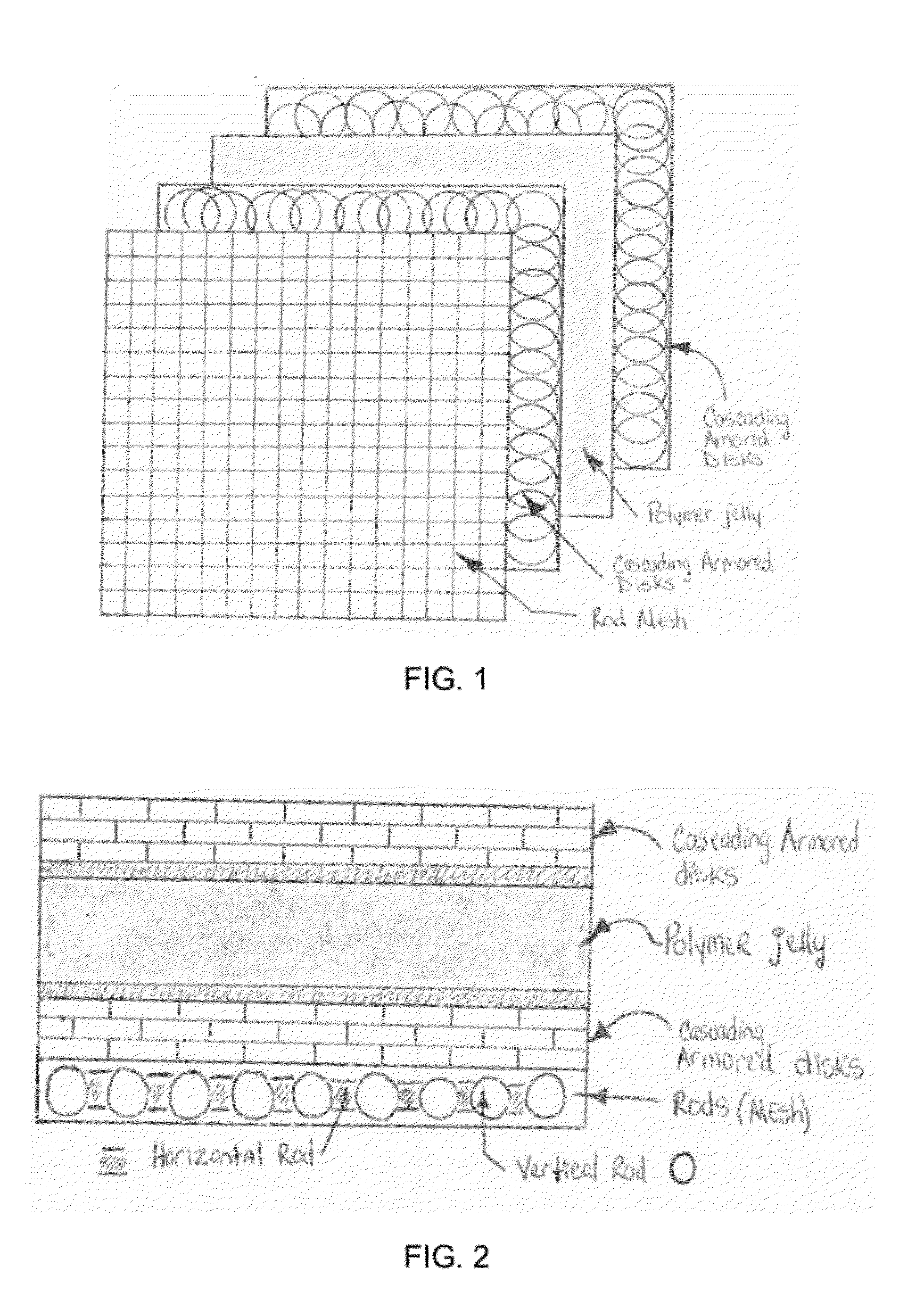

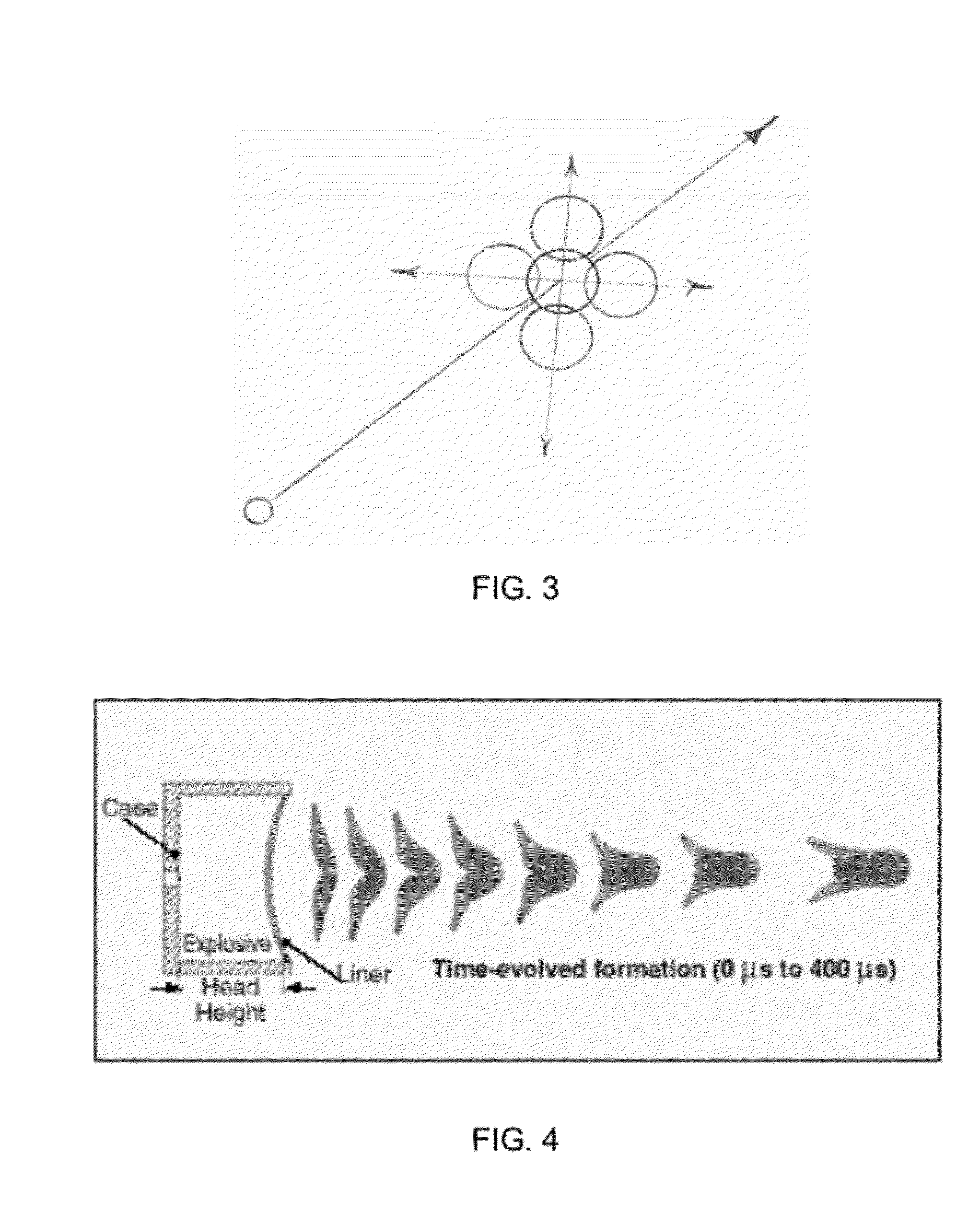

[0036]We describe a three step approach for mitigating the effects of an EFP device which is called the “SCS” system and method. The acronym “SCS” stands for “split”, “cool”, and “slow,” which describes how the explosively formed projectile is treated. This three step approach offers a unique method for mitigating the effects of an EFP by weakening or reducing the effect of the penetrator by reducing its mass, its temperature, and its velocity. Although there are three primary steps to mitigation, there exists no set value for the number of layers that compose the 3 steps. It is advantageous to manipulate both the number of individual layers as well as their perspective positions in different combinations. These modifications each have as their effects remain the same, namely to split a penetrator to reduce the mass of individual portions relative to the original mass and to increase the surface to volume ratio of the individual portions relative to the original mass, to cool the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com