Automotive HVAC Diffuser With Cooperating Wall Guide And Vane

a technology for hvac diffusers and automotive hvac systems, which is applied in ventilation systems, heating types, lighting and heating apparatuses, etc. it can solve the problems of less able to affect the air flow near the midline of the diffuser, the height of the interior vanes from the corresponding wall is restricted, and the flow is not uniform, so as to achieve uniform airflow and high flow. the effect of the region

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

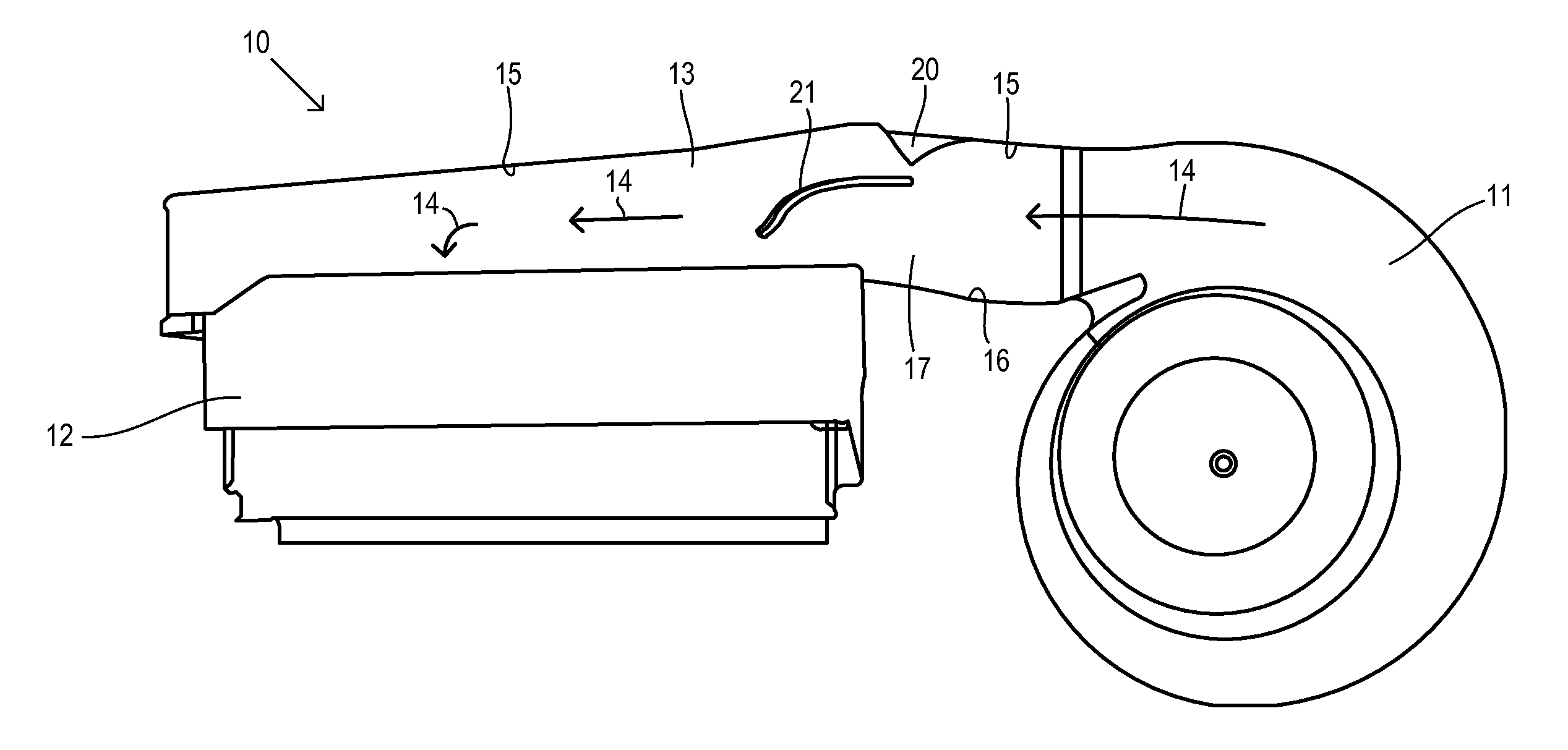

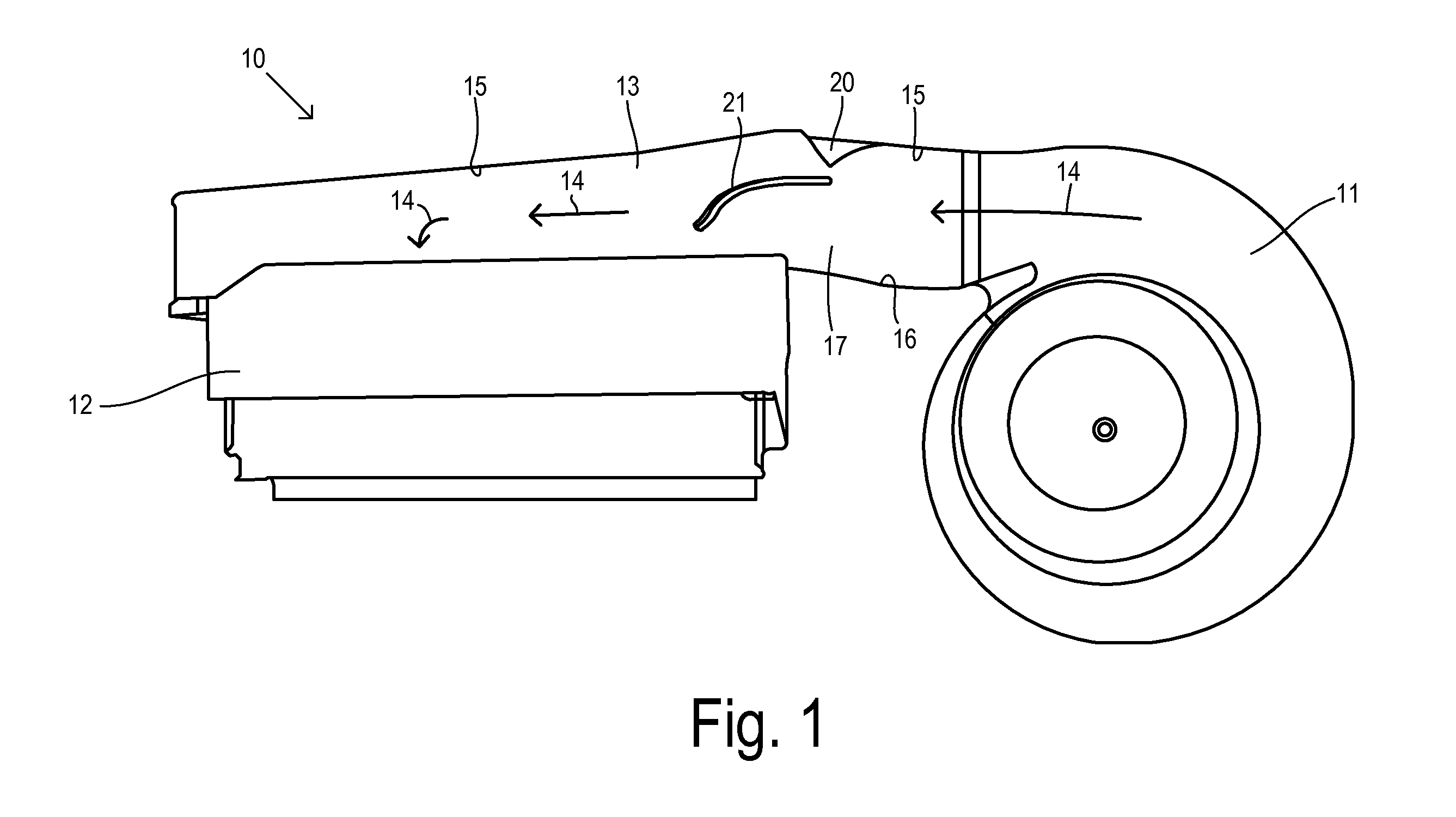

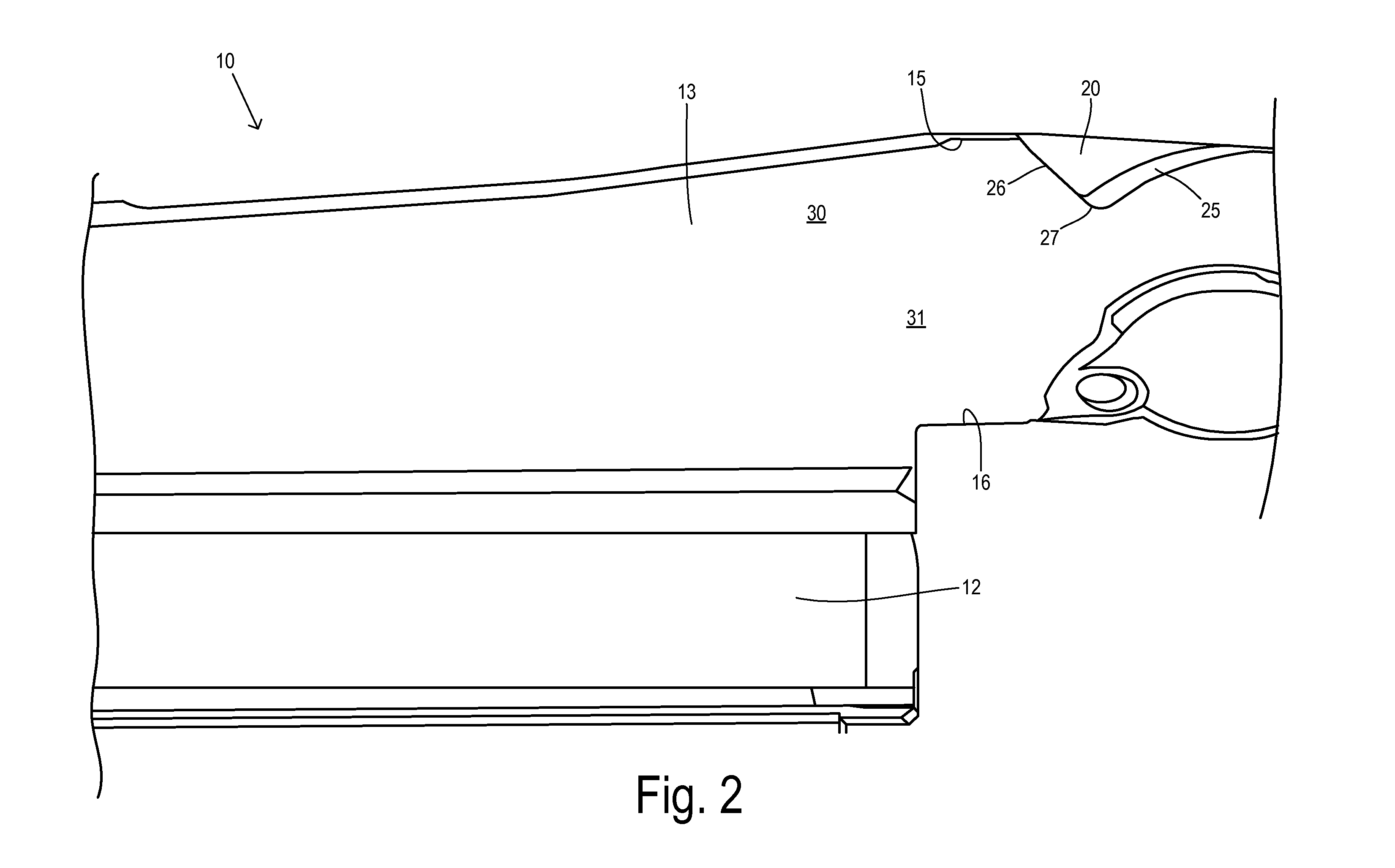

[0021]Referring now to FIG. 1, an HVAC case 10 includes a blower section 11, an evaporator section 12, and an intervening diffuser section 13. Blower section 11 receives a motor-driven bladed wheel (not shown) for created an air flow of fresh or recirculated air that is guided through diffuser section 13 to an evaporator core (not shown) mounted in evaporator section 12. Guided air 14 follows an airflow path and is required to make an approximately right angle turn in order to enter evaporator is section 12.

[0022]Diffuser section 13 includes an outer wall 15, an inner wall 16, a floor 17, and a ceiling (not shown) that surround a generally longitudinal axis of diffuser section 13 that extends between an inlet from the blower section 11 and an outlet to evaporator section 12. Due to centrifugal affects, a region of high flow is generally associated with outer wall 15 which results in non-uniform entry of the air flow into evaporator section 12. To improve uniformity and to reduce the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com