Pet enclosure with dual axes swivel connector

a technology of swivel connectors and enclosures, applied in the direction of hinges, wing accessories, couplings, etc., to achieve the effect of reducing noise, facilitating offsetting of panels, and reducing overall nois

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

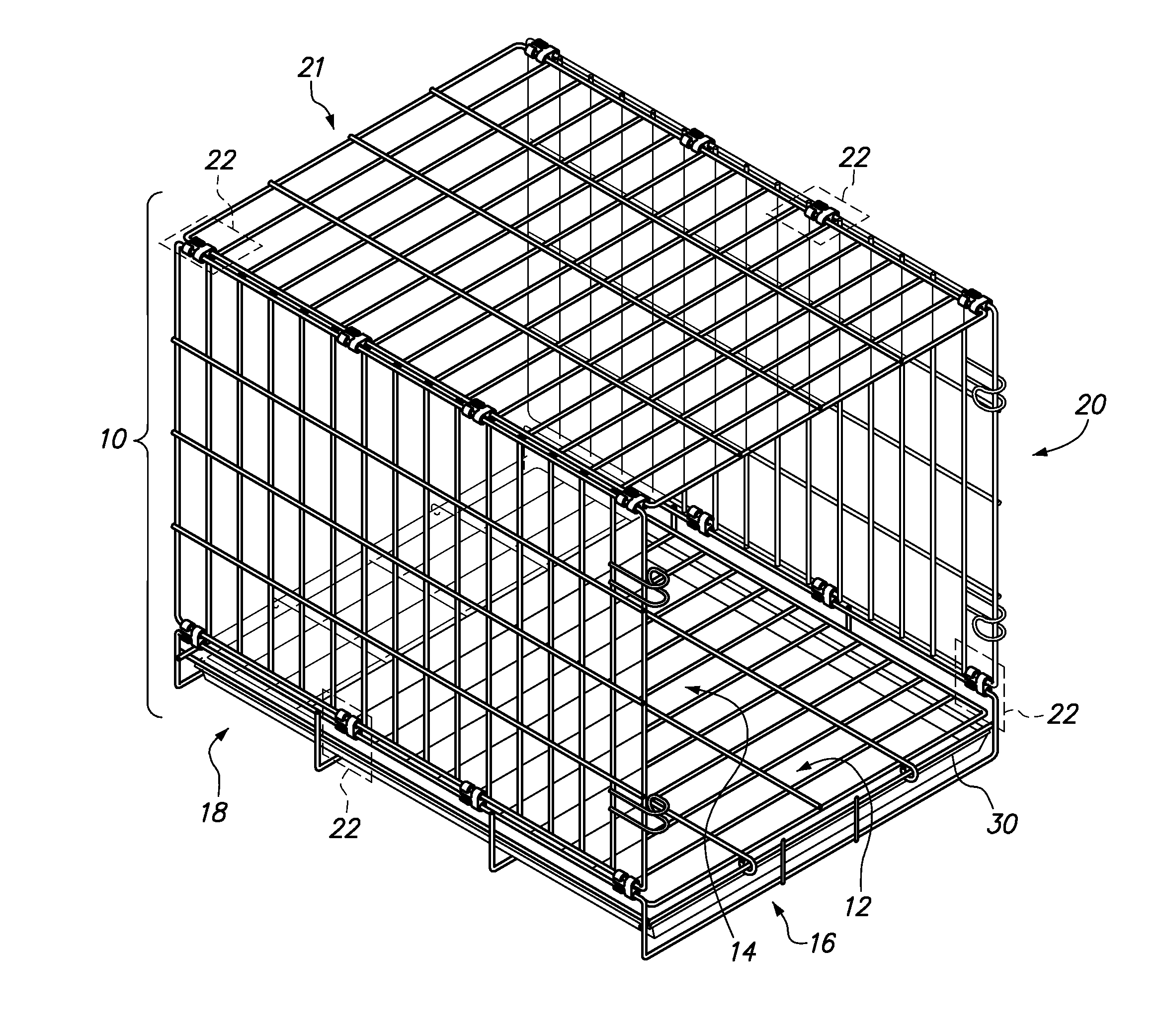

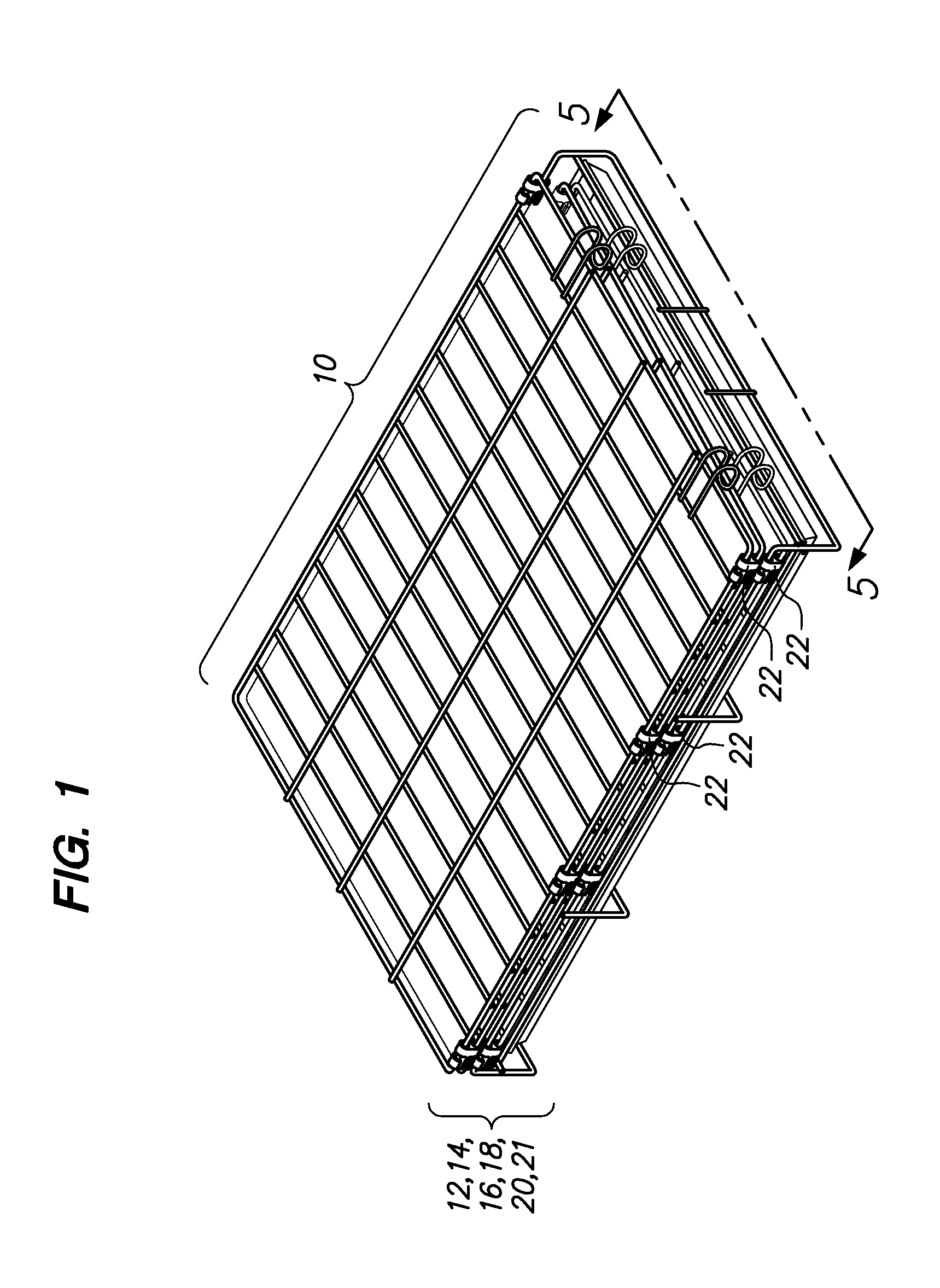

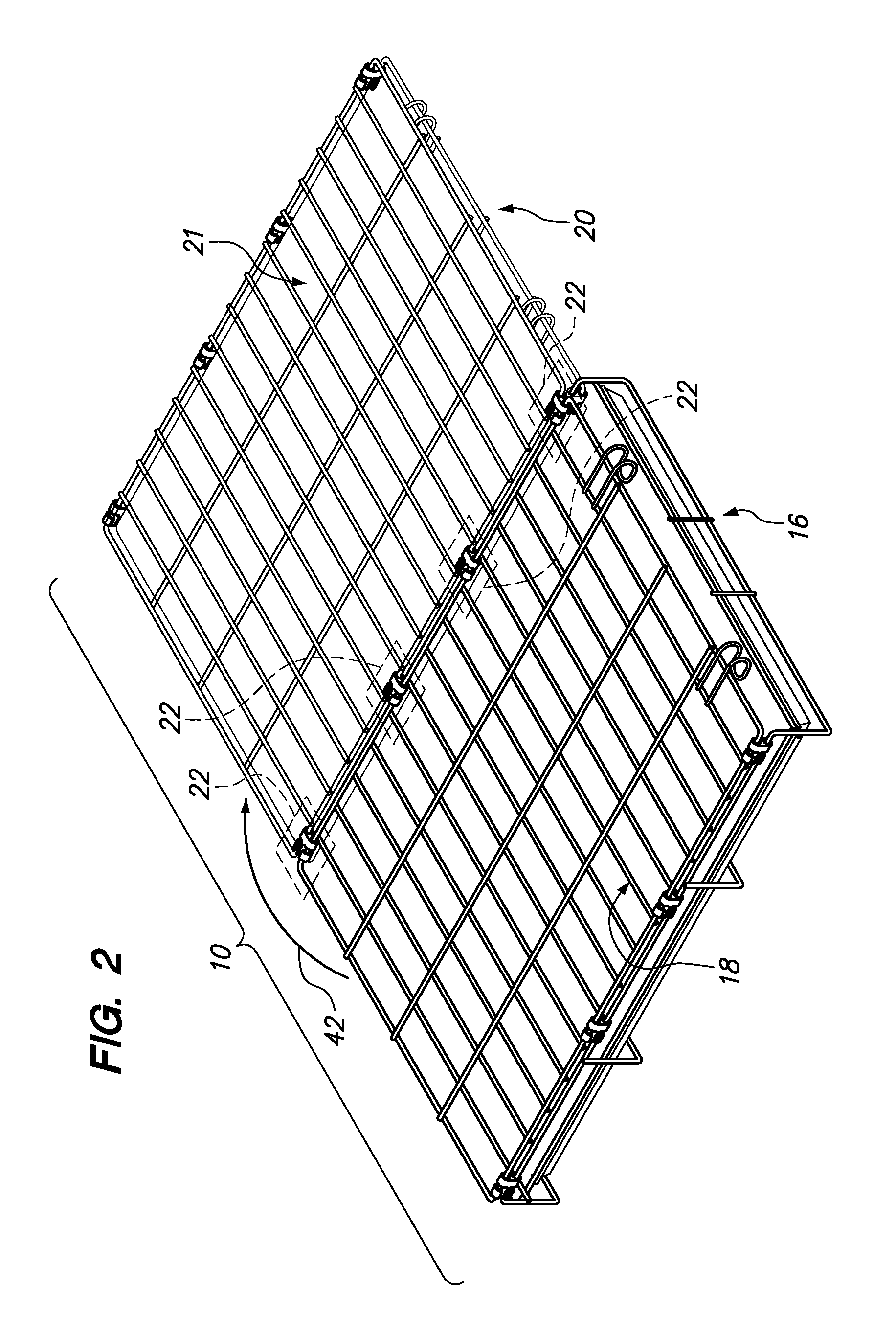

[0059]Referring now to the drawings, a collapsible enclosure 10 is shown. When the enclosure 10 is in storage or being transported, the enclosure 10 may be traversed to the collapsed position shown in FIG. 1. During use, the enclosure 10 may be traversed to the erected position shown in FIG. 3. FIG. 3 illustrates the erected position of the enclosure 10 with front and back panels 12, 14 still in the folded configuration. The various panels, namely, a bottom panel 16, left and right side panels 18, 20 and top panel 21 may be rotatably connected to each other by way of a dual axes swivel connector 22, 100. A first embodiment of the dual axes swivel connector 22 is shown and described in relation to FIGS. 1-12. A second embodiment of the dual axes swivel connector 100 is shown and described in relation to FIGS. 13-17. It is also contemplated that the front and back panels 12, 14 may be rotatably connected to the bottom panel 16 by way of the dual axes swivel connector 22, 100.

[0060]Ref...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elevations | aaaaa | aaaaa |

| elevation | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com