Coupler with Magnet

a magnet and coupling technology, applied in the field of couplings, can solve the problems of user error, lost operator time, etc., and achieve the effect of safe us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

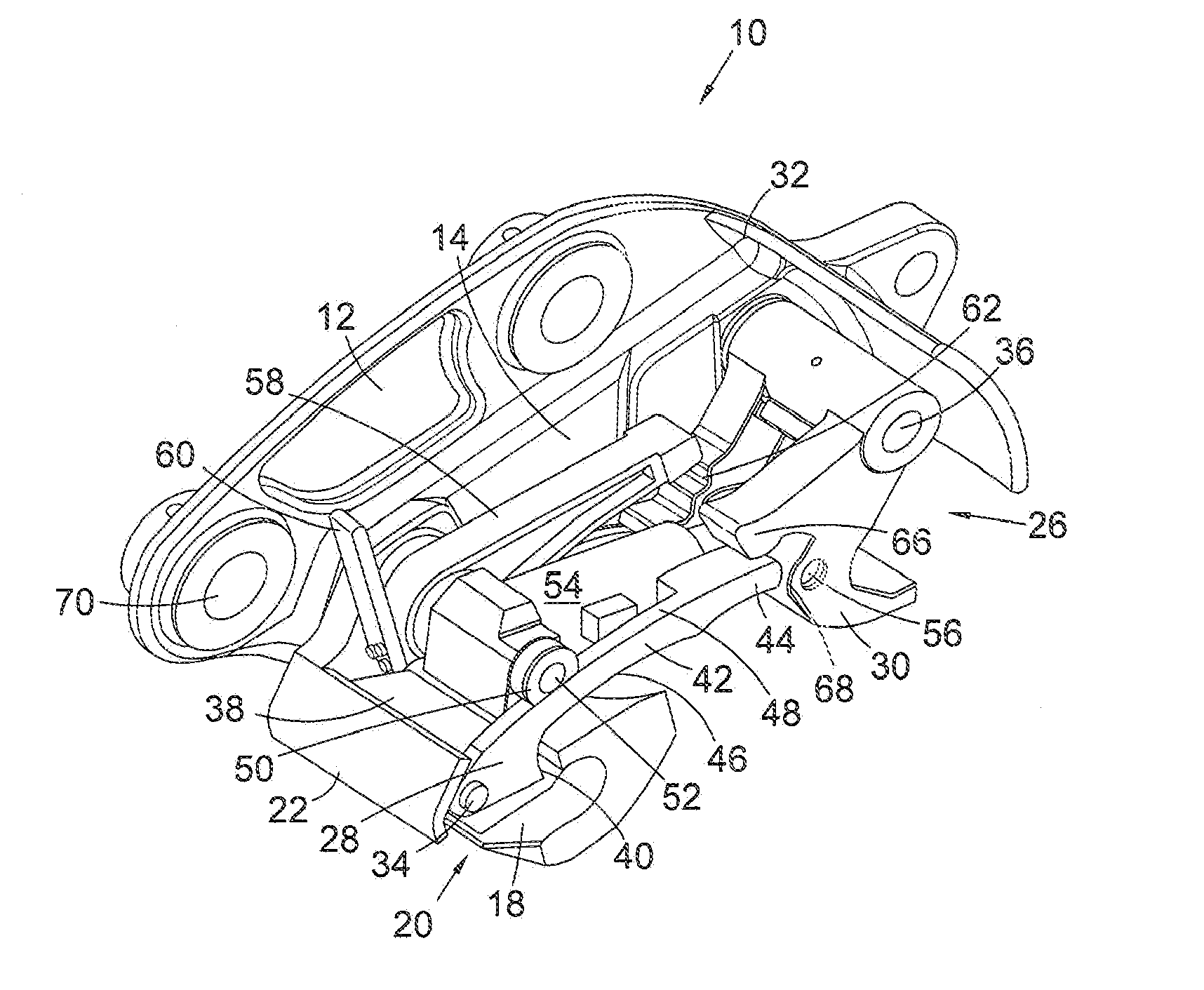

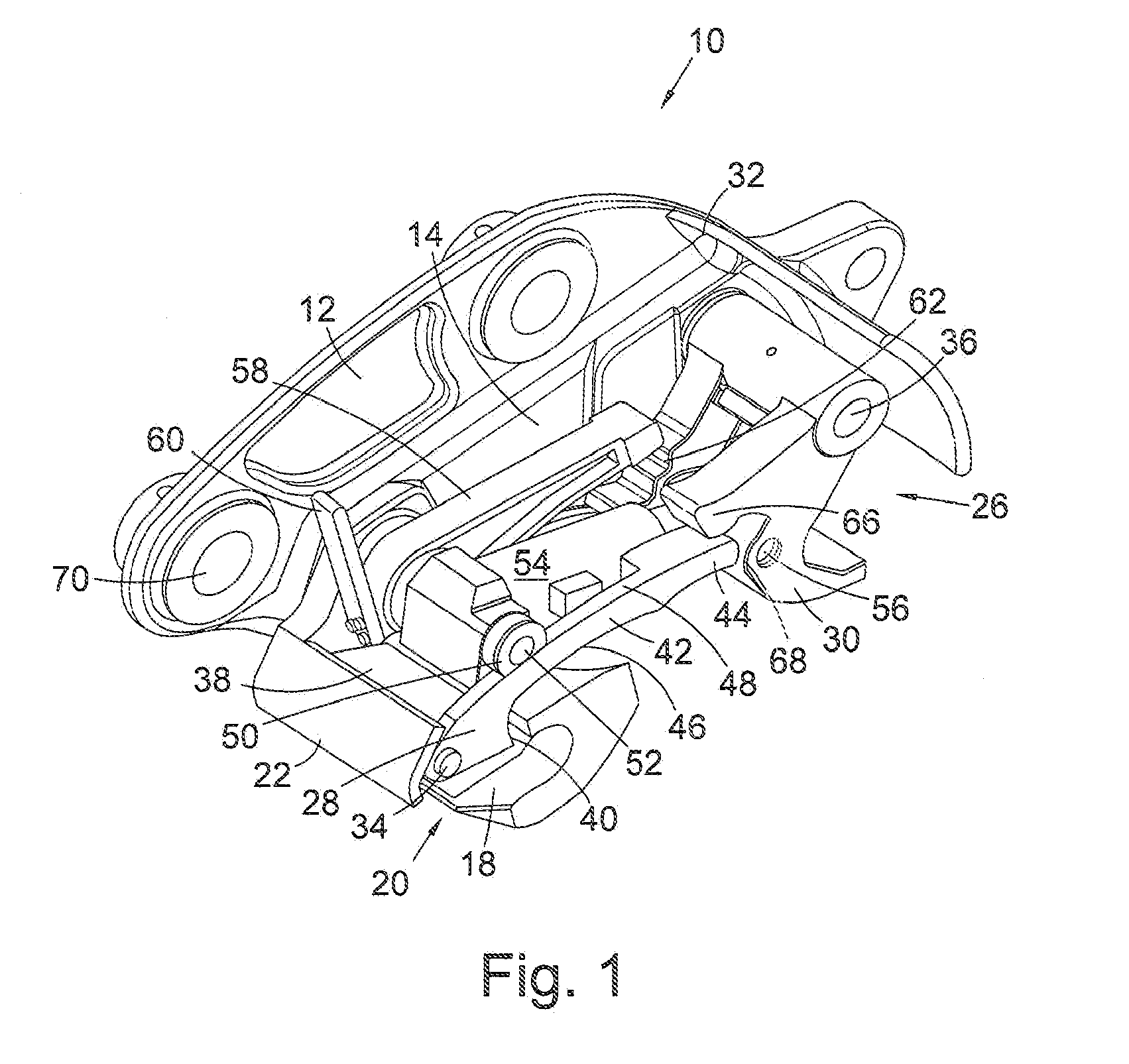

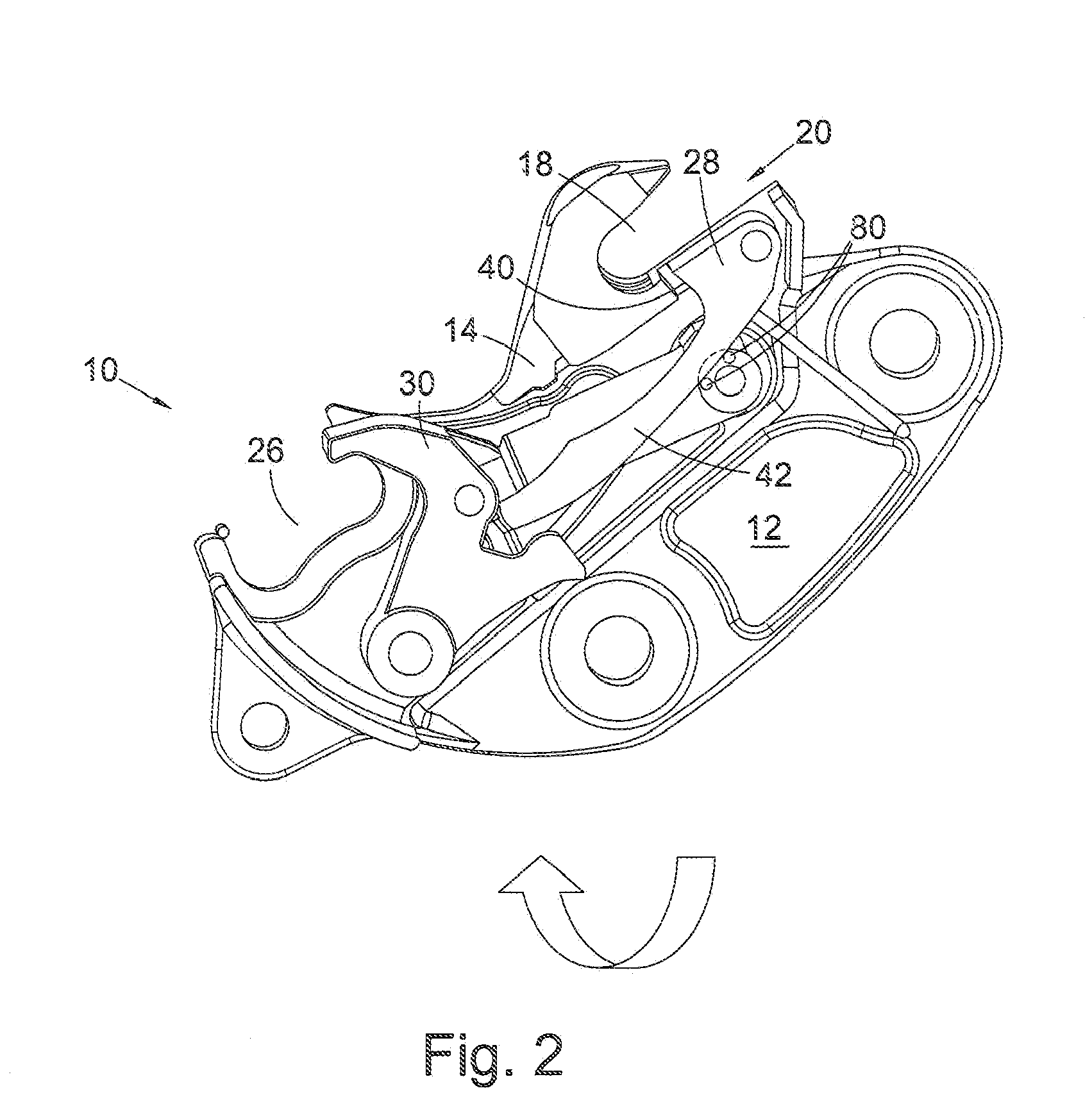

[0087]Referring first of all to FIG. 1, there is shown a coupler 10 having a first half 12 for mounting onto an end of an excavator arm of an excavator (not shown) and a bottom half 14 in which is mounted the working mechanisms of the coupler 10. In this illustrated embodiment, the top half 12 of the coupler 10 is mounted onto the excavator arm of the excavator by a pair of accessory pins (not shown), as is conventional for excavator couplers and accessories. Other known mechanisms for mounting couplers to an excavator arm can also be used instead, by making appropriate changes to the top half of the coupler.

[0088]The bottom half 14 of the coupler accommodates the working mechanism of the coupler 10. It consists of a first jaw 18 having an opening 20 at or near the front 22 of the coupler 10. That opening faces the forwards direction relative to the coupler. The first jaw 18 is for receiving a first accessory pin or accessory attachment member of an accessory, such as an excavator b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com