Flood wall protection system

a flood wall and protection system technology, applied in the direction of liquid handling, packaging goods, grains, etc., can solve the problems of no wood, no special and unreliable parts, etc., and achieve the effect of more security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

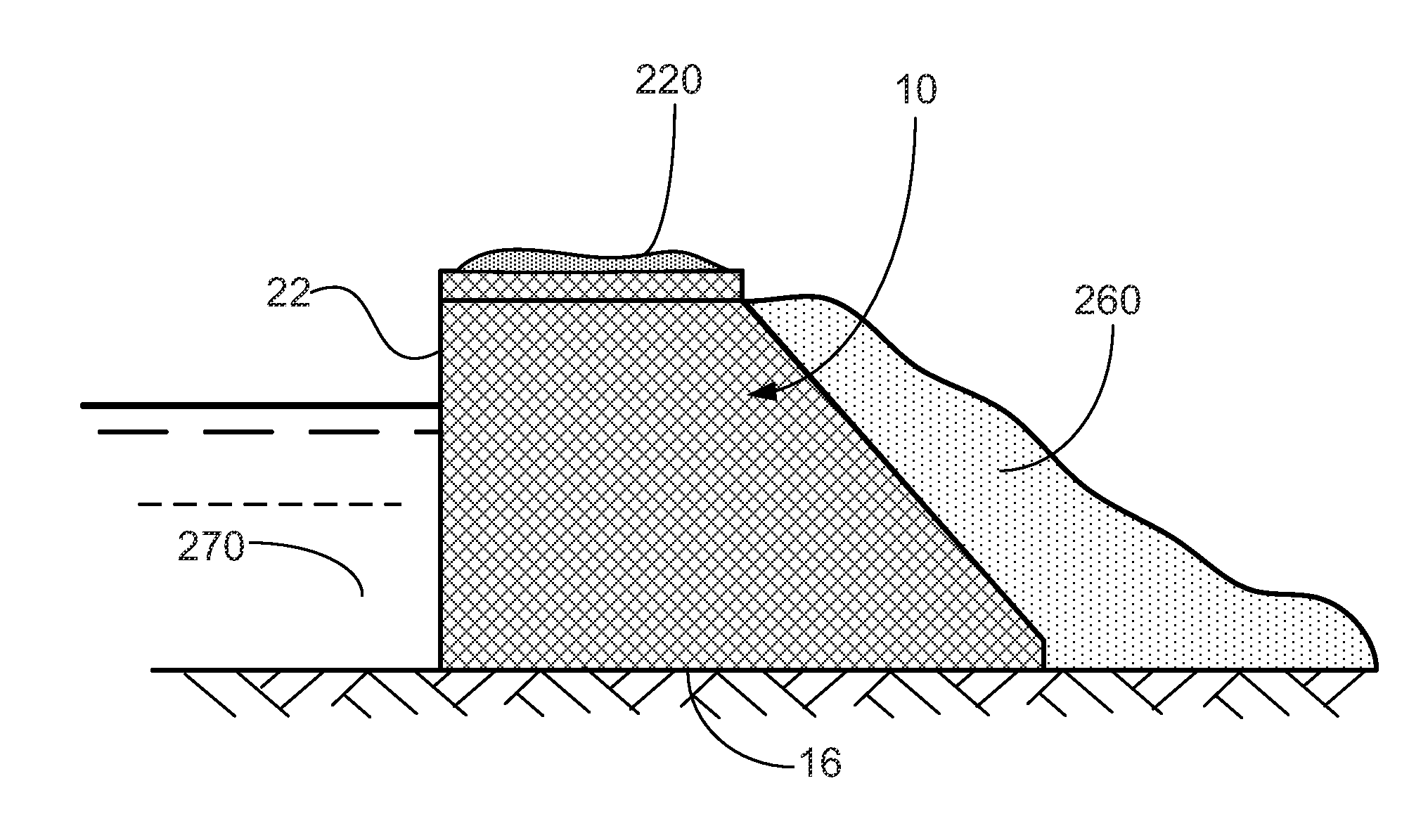

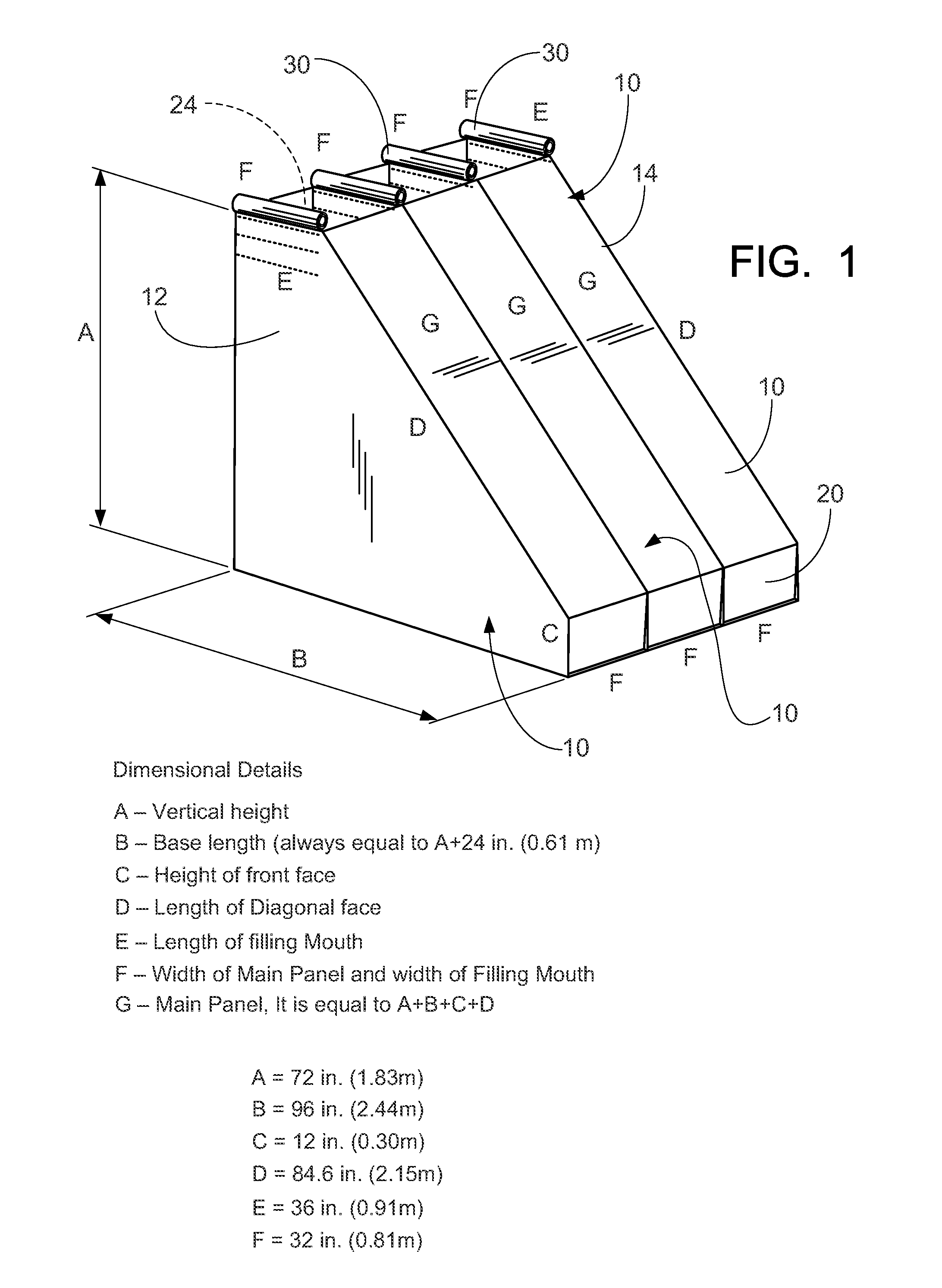

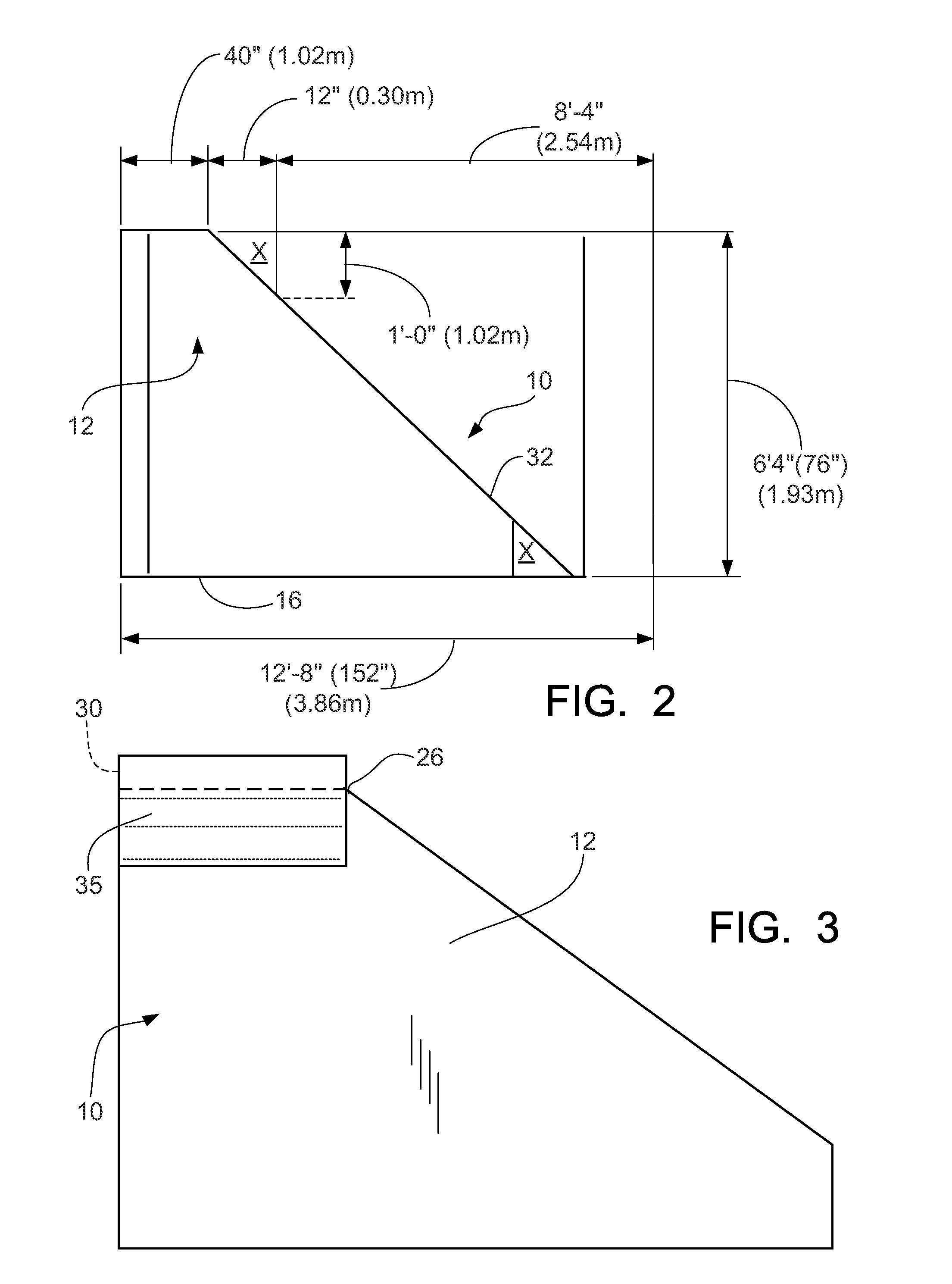

[0040]FIGS. 1 through 19 illustrate the TrapBag® system and method the present invention of filling a continuing series of bags or chambers to ultimately define a barrier wall.

[0041]Prior to a discussion of the drawing figures, it should be understood that this invention replaces the method of support as seen in the prior art with a unique sleeve support system. Instead of four individual plastic hangars that can break and allow connecting walls to sag and misshape, this invention uses a continuous sleeve that is fitted into each connecting wall. This sleeve provides a stiff and straight support for the entire length of the connecting walls by use of a metal rod which is threaded through the sleeve and supported by the metal rails of the sled or any other hanging device that may be used.

[0042]This complete support of the connecting wall completely eliminates the sagging during the filling process. It also spreads out the weight of the sand and dirt during the sled movement. The two ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com