Recoil, sound and flash suppressor

a suppressor and sound technology, applied in the field of suppressors, can solve the problems of neither creating the internal geometry to efficiently suppress sound and flash, and directing combustion gas toward the object, so as to overcome the present ineffectiveness of the attached muzzle device, effectively negate, and diminish the effect of sound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

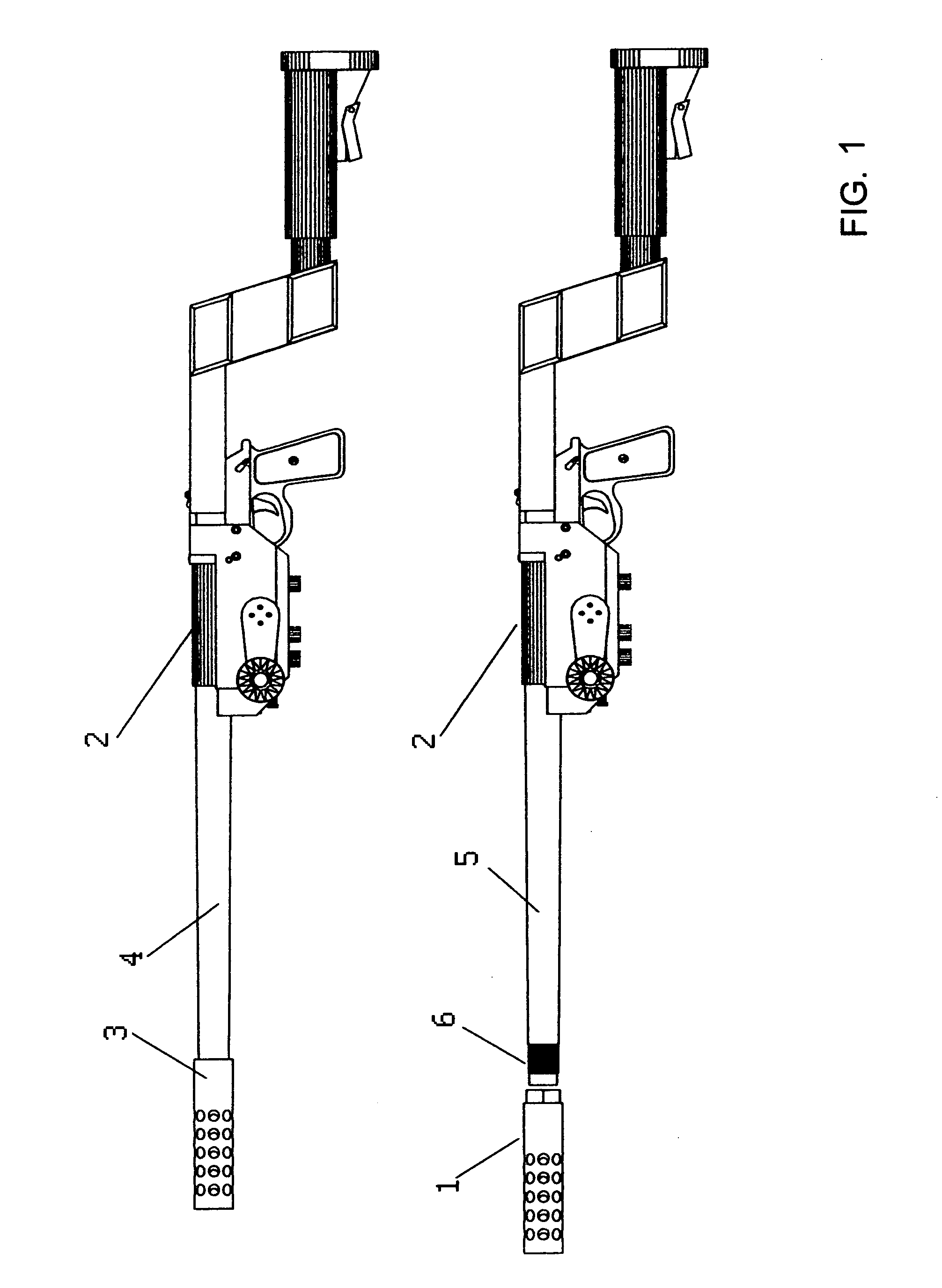

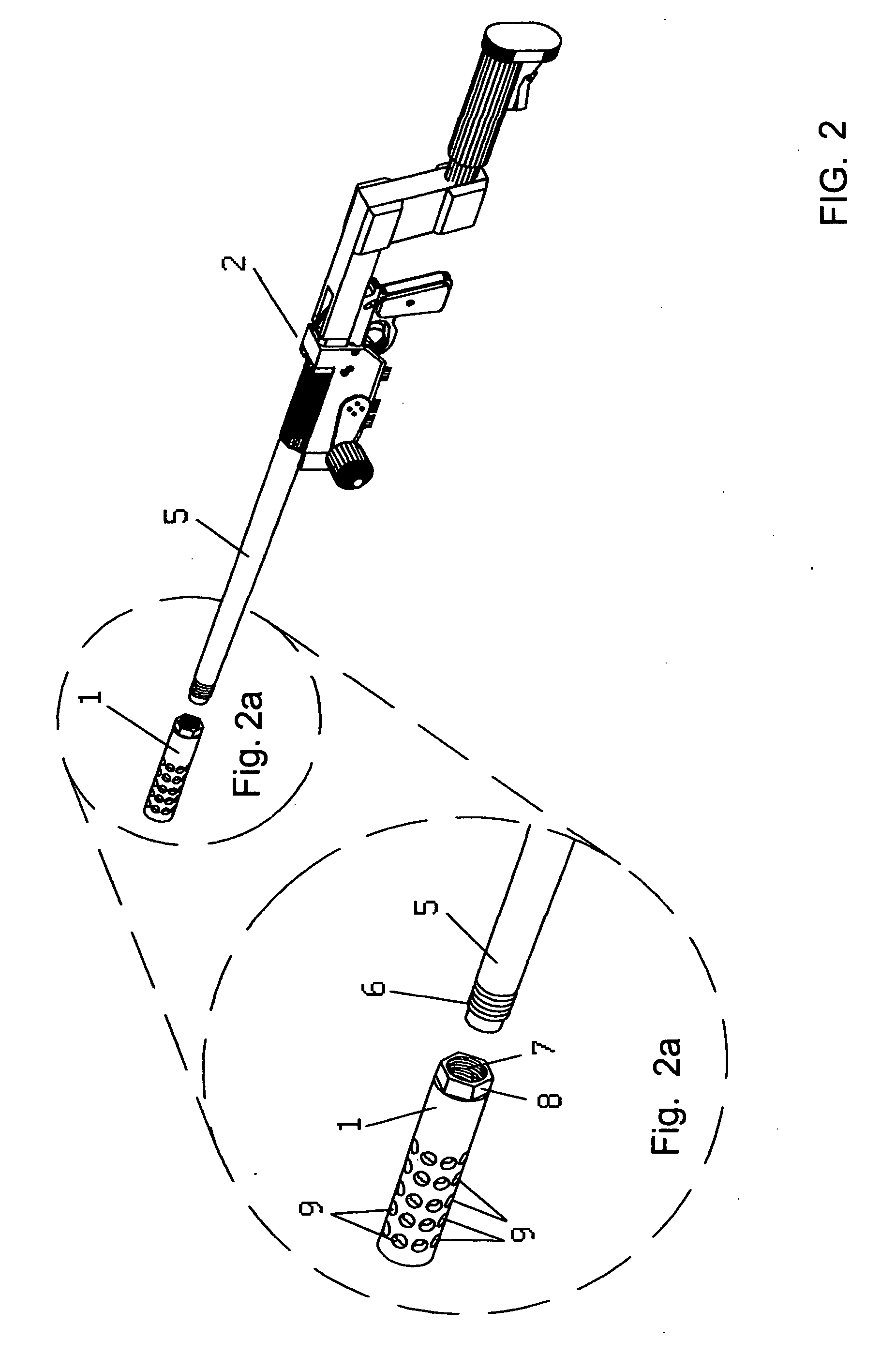

[0012]Referring to FIG. 1, the top illustration shows a large caliber rifle 2 with the fixed or permanent embodiment of the Recoil, Sound and Flash Suppressor 3 machined to the rifle barrel 4 as one part. The bottom illustration on FIG. 1 shows how the removable embodiment of the Recoil, Sound and Flash Suppressor 1 with internal threads machined in the end of it can be attached to rifle barrel 5 through the use of threads 6 machined on to the end of barrel 5.

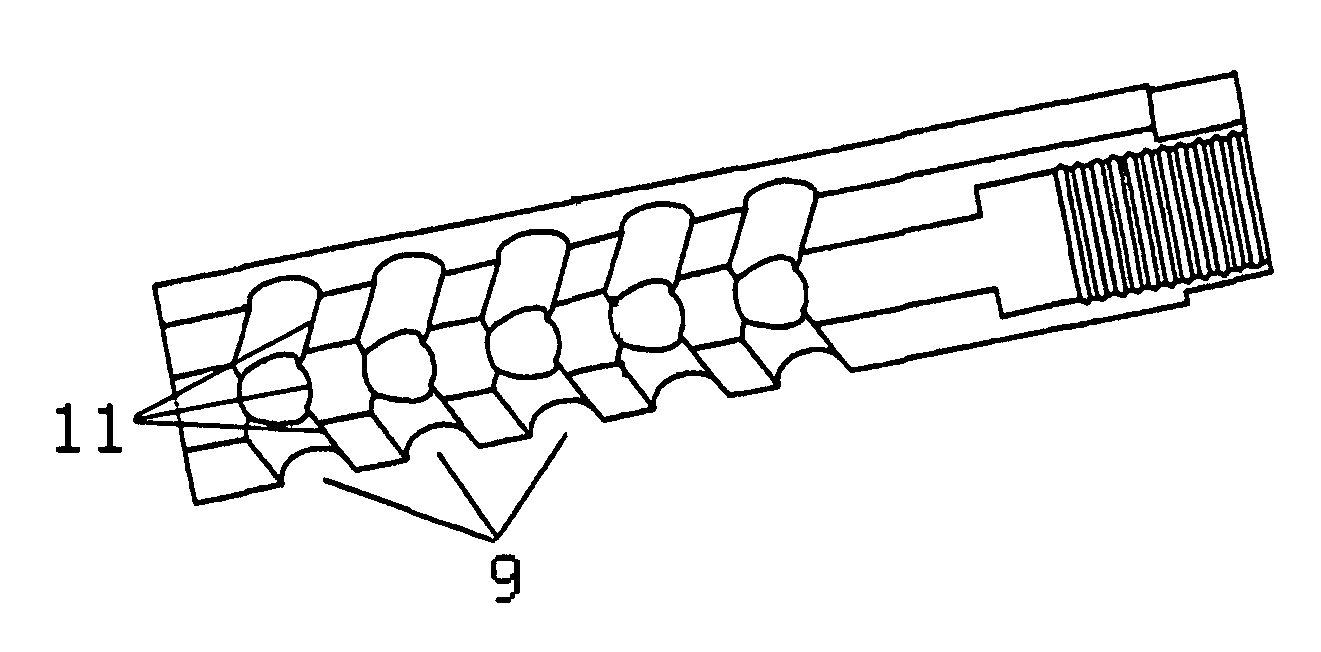

[0013]Referring to FIG. 2, the Recoil, Sound and Flash Suppressor 1 is attachable to rifle 2, or other firearm, with the use of internal threads 7 and hex area 8 which allows a wrench to tighten or loosen the removable Recoil, Sound and Flash Suppressor 1 and attach it to barrel 5 which has threads 6 machined on the end of it. Ports / holes 9 are machined to allow controlled escape of pressurized combustion gases from within the newly designed removable Recoil, Sound and Flash Suppressor 1 and the permanently attached Recoil, Sou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com