Inflation and monitoring assembly for a pressure cuff

a technology of inflation and monitoring assembly, which is applied in the direction of catheters, medical devices, other medical devices, etc., can solve the problems of not being reusable, and achieve the effect of convenient visual observation, easy and efficient monitoring of pressure within the cuff, and easy determinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

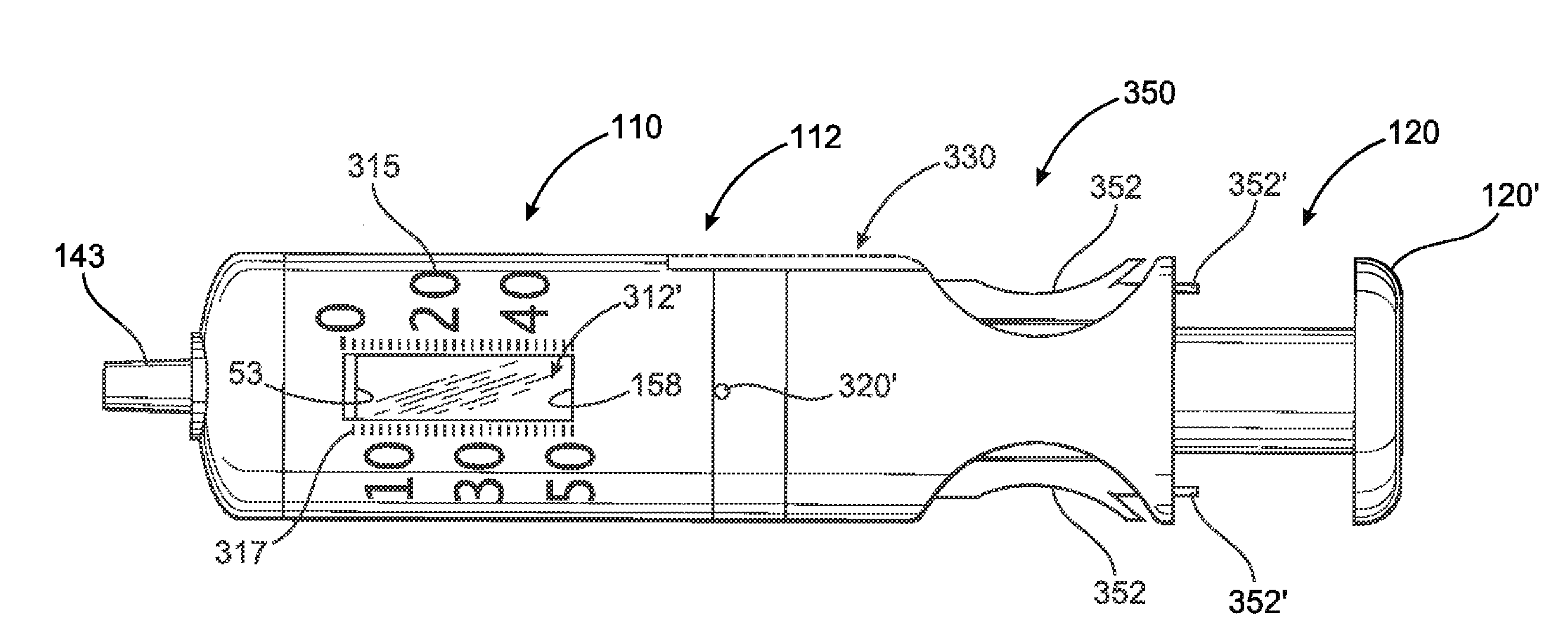

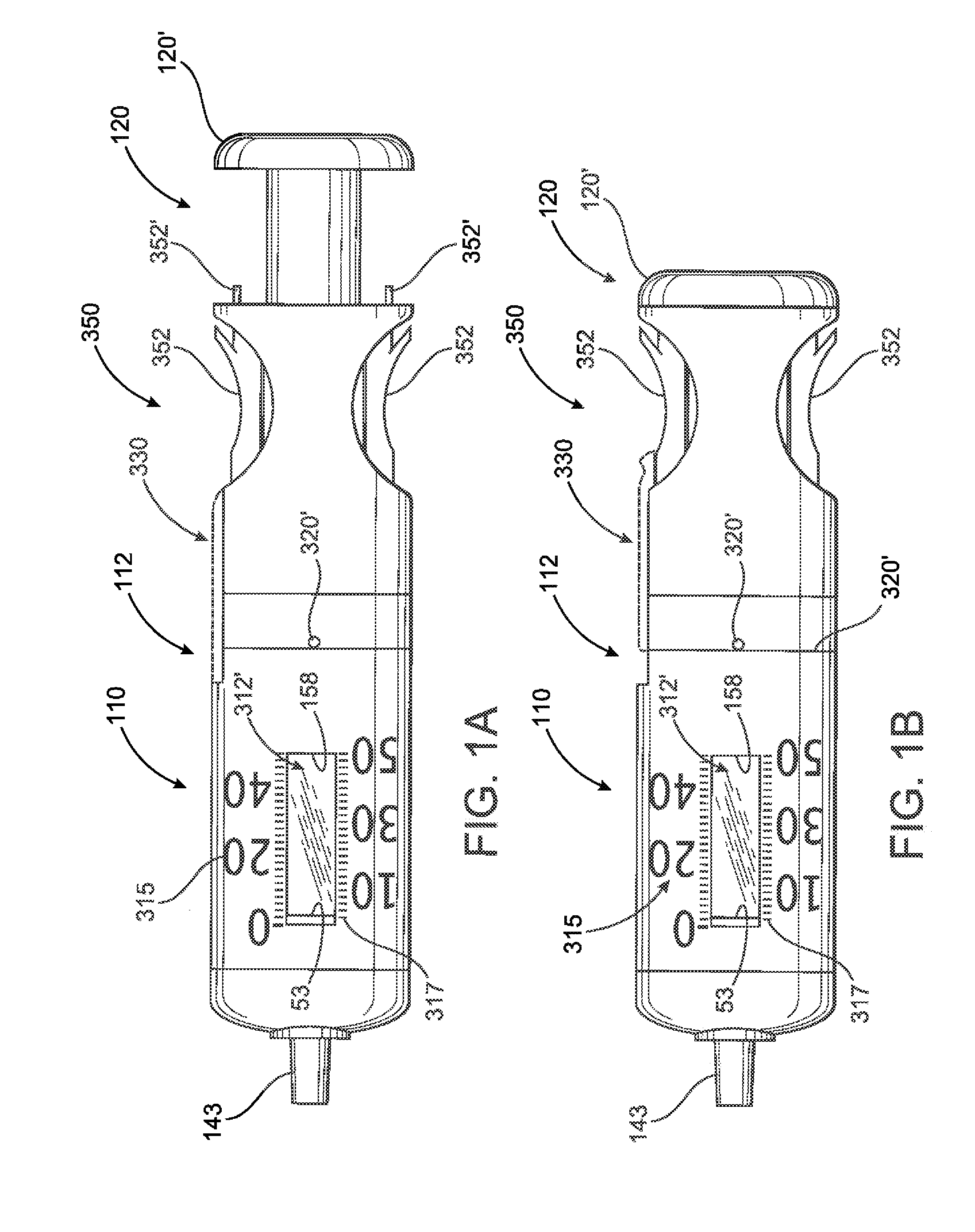

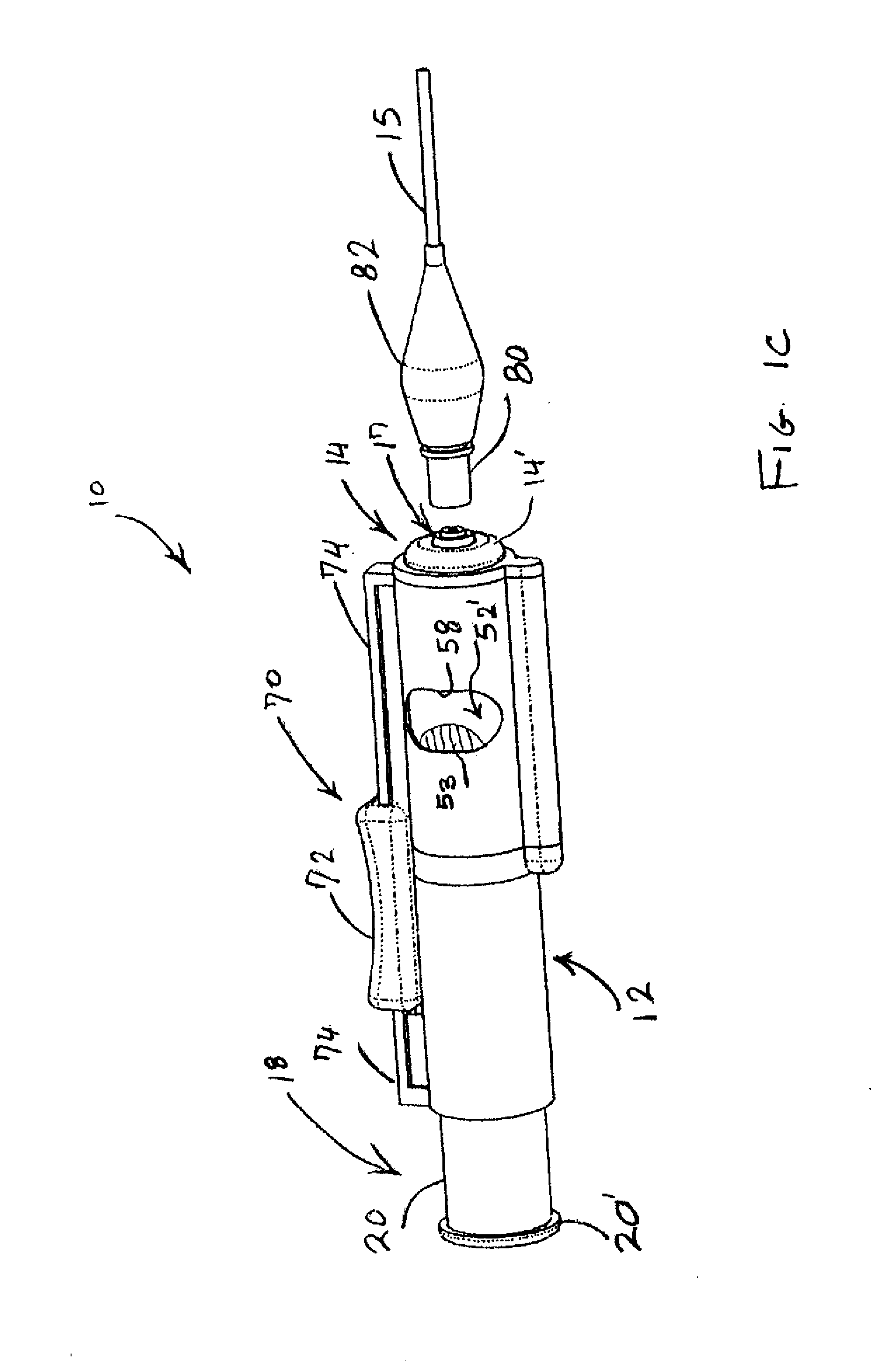

[0061]As shown in the accompanying drawings, the present invention is directed to an inflation and pressure monitoring assembly generally indicated as 10. The assembly 10 structured to inflate and monitor the pressure within a retaining cuff or pressure cuff of a medical device, including in the preferred embodiment the type associated with an endotracheal tube. It is understood, however, that the pressure cuff, often referred to as a balloon in some devices, could be included as part of medical devices used in balloon kyphoplasty, balloon sinuplasty, coronary or vascular balloon angioplasty and / or the delivery of stents, balloon esophageal dilation, and the dilation of strictures and sphincters, balloon dilatation of the nephrostomytract, and / or Swan Ganz catheters, among other medical devices.

[0062]More specifically, the assembly 10 includes a generally elongated casing 12 having a distal end generally indicated as 14 structured to be interconnected to an inflation lumen 15, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com