Assembly for Actuating a Downhole Tool

a technology for actuating tools and downholes, applied in the direction of fluid removal, borehole/well accessories, construction, etc., can solve problems such as failure of the ball or sleev

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

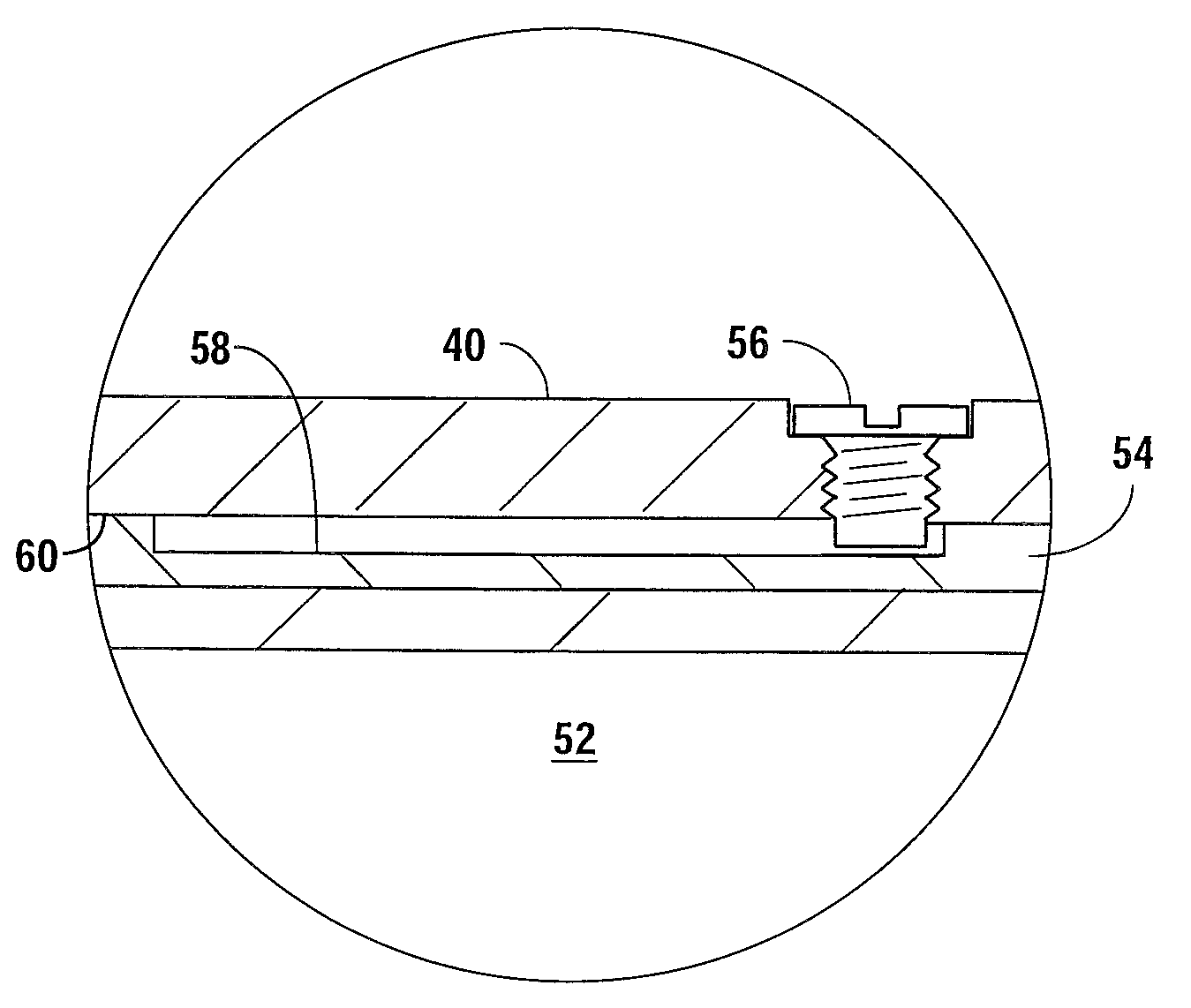

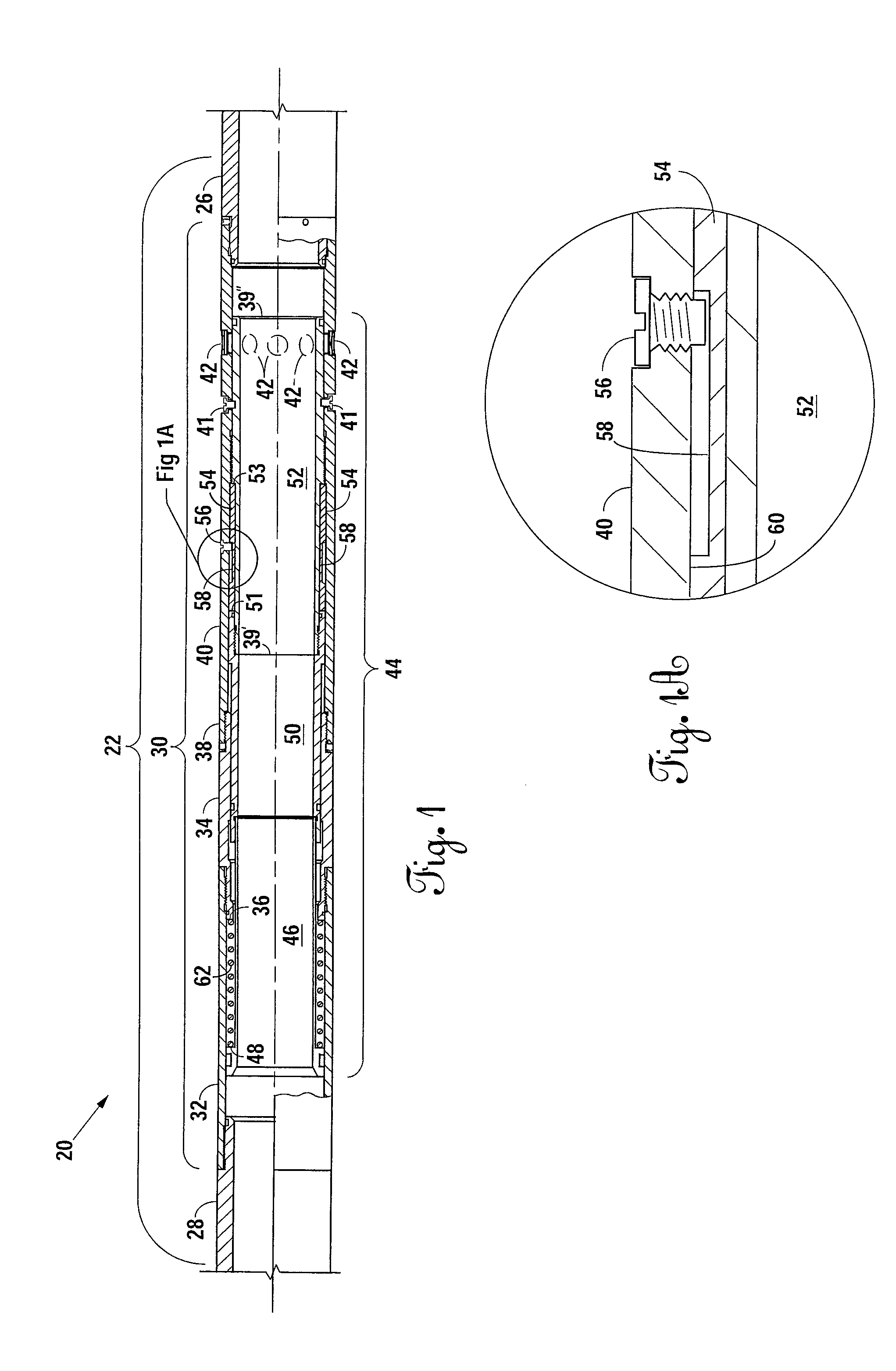

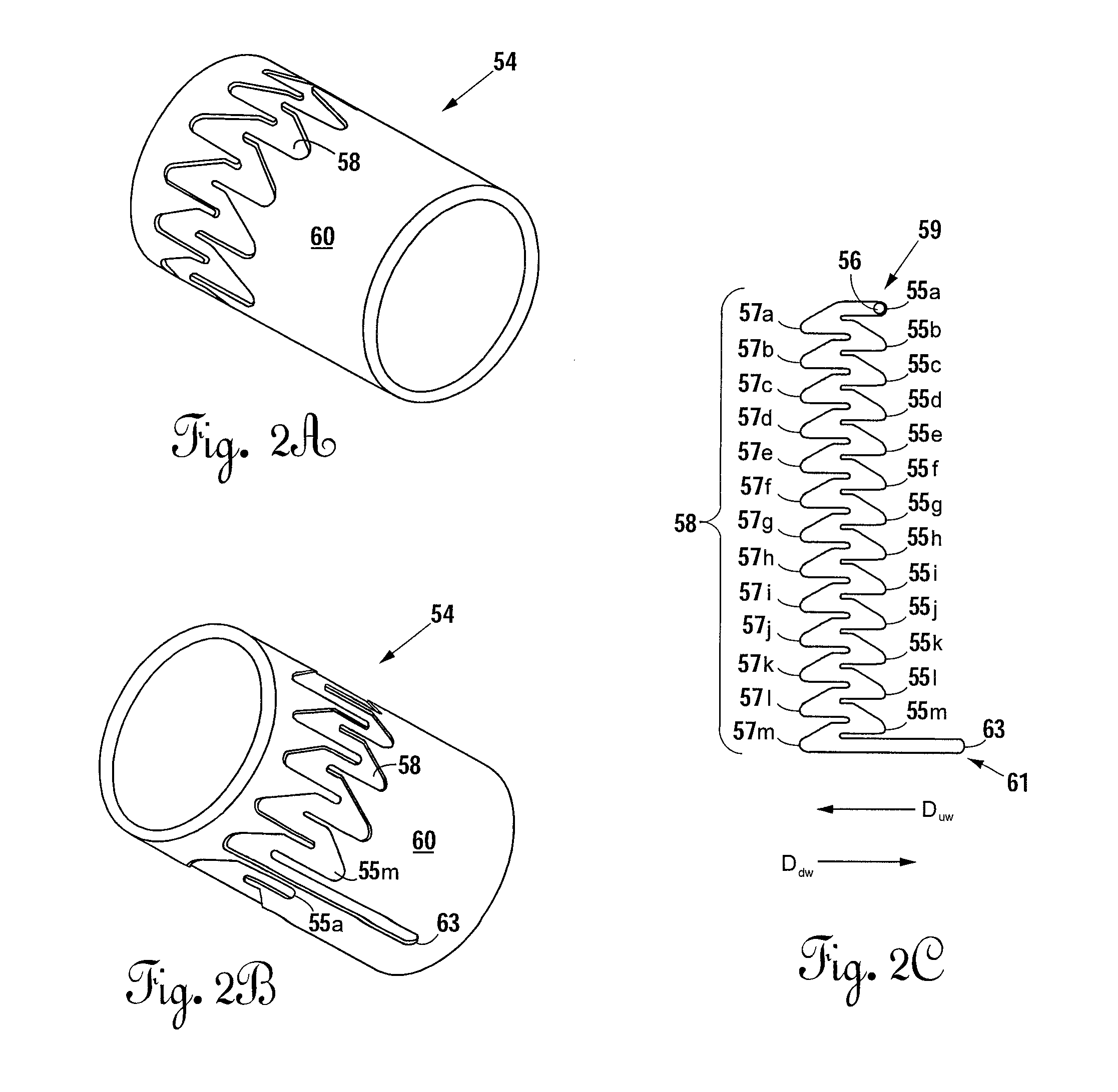

[0029]When used with reference to the figures, unless otherwise specified, the terms “upwell,”“above,”“top,”“upper,”“downwell,”“below,”“bottom,”“lower,” and like terms are used relative to the direction of normal production through the tool and wellbore. Thus, normal production of hydrocarbons results in migration through the wellbore and production string from the downwell to upwell direction without regard to whether the tubing string is disposed in a vertical wellbore, a horizontal wellbore, or some combination of both. Similarly, during the fracing process, fracing fluids move from the surface in the downwell direction to the portion of the tubing string within the formation.

[0030]FIG. 1 depicts a valve seat assembly 22 in which the tool to be actuated is a ported sleeve. A tubing string section 26 provides a fluid communication path between the ported sleeve assembly 22 and other downhole tools or accessories.

[0031]The ported sleeve assembly 22 can transition between three stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com