Horizontal articulated robot

a robot and horizontal technology, applied in the field of horizontal robots, can solve the problems of deteriorating responsiveness to movement and positioning precision, difficult to reduce the minimum radius rmin, and restricted miniaturization of the arm frame, so as to achieve the effect of reducing the increase in mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044]Embodiments of the invention will be described with reference to the drawings. Hereinafter, a horizontal articulated robot according to a first embodiment of the invention will be described in detail.

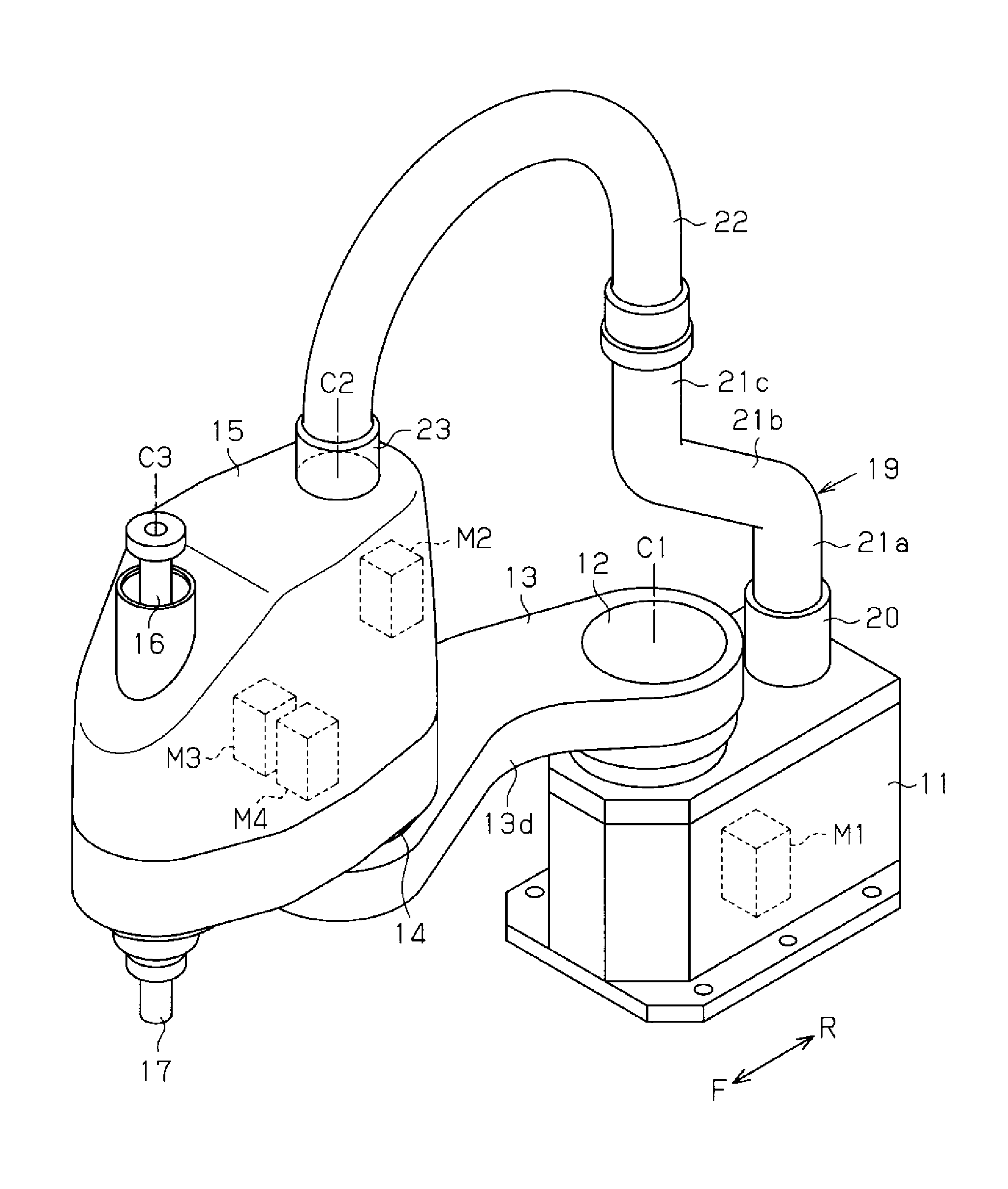

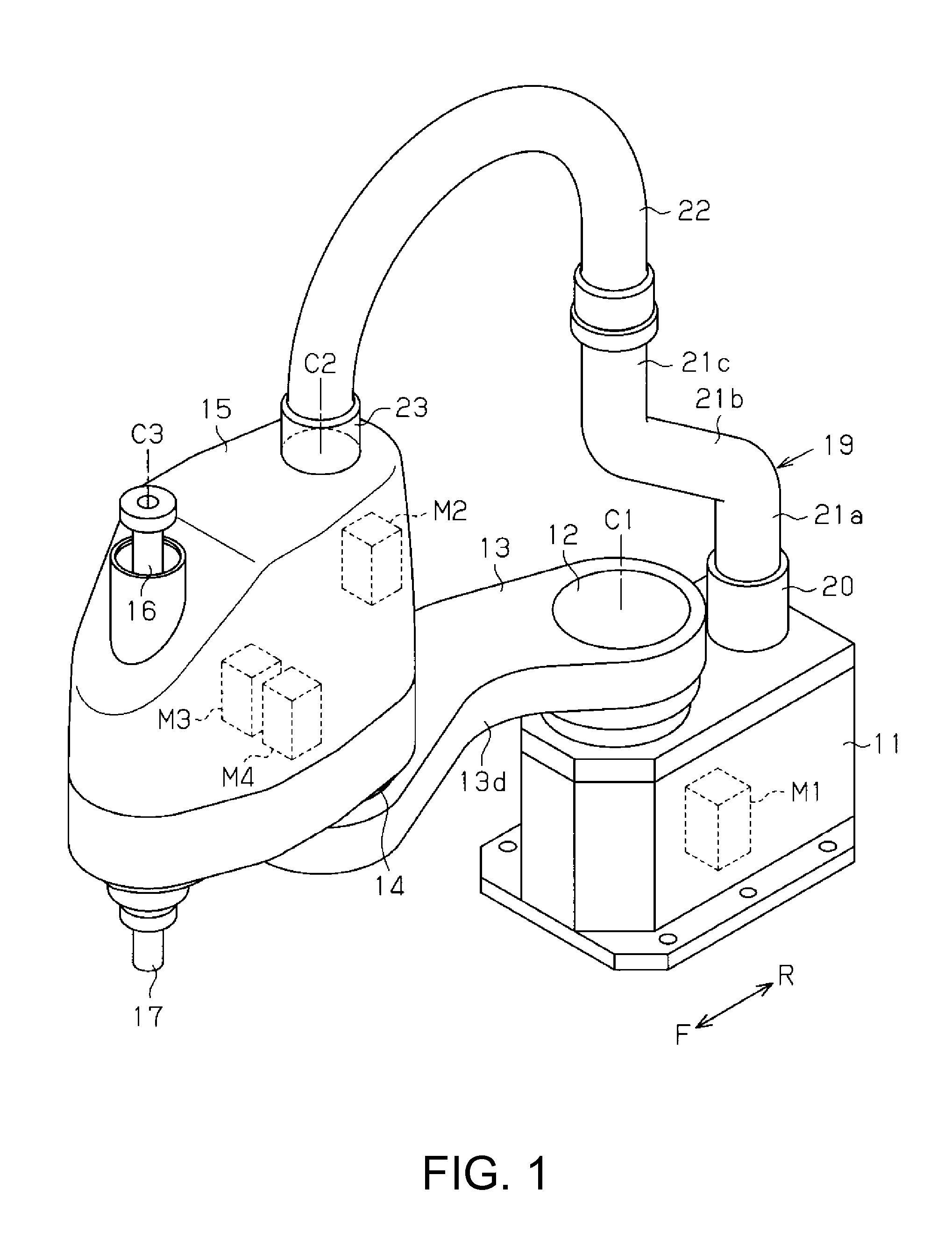

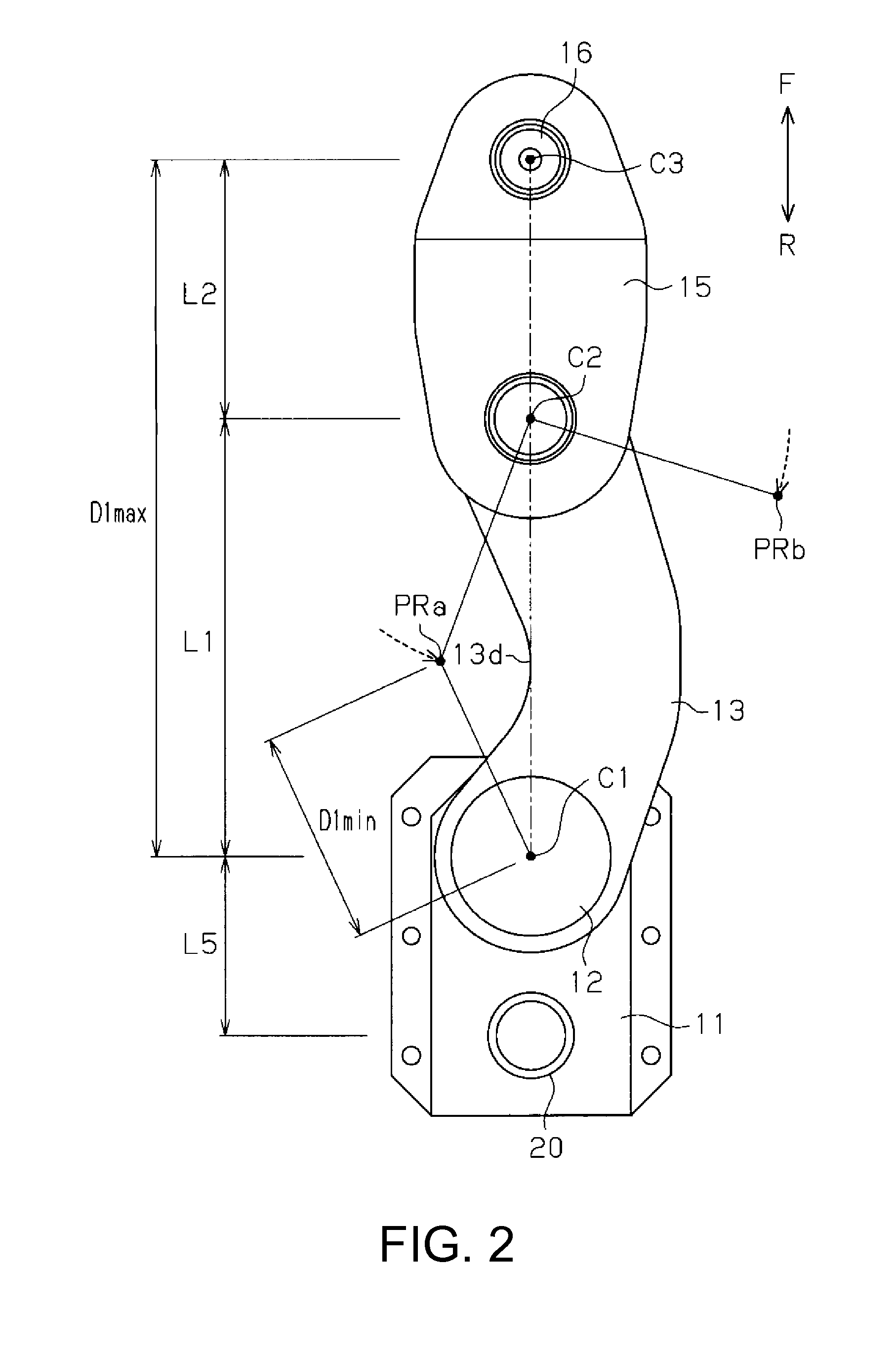

[0045]FIG. 1 shows a perspective structure of the horizontal articulated robot (a SCARA robot). FIG. 2 shows a top-surface structure of the SCARA robot.

[0046]As shown in FIG. 1, the SCARA robot includes a base 11 as a supporting member disposed on a floor or the like. At an upper end portion of the base 11 is provided a connection shaft 12 that rotatably supports a base end portion of a first arm 13, as a rotating member. The connection shaft 12 is formed in a cylindrical shape with an axial center C1 and is provided rotatably around the axial center C1 on the base 11. The connection shaft 12 is rotated forward or backward by a first motor M1 provided in the base 11. Thereby, the first arm 13 rotates around the axial center C1 of the connection shaft 12 rotated by the first motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com