Corner molding for sealing vinyl liners to pool fixtures

a technology for sealing and pool fixtures, applied in the field of pool equipment and installation, can solve the problems of time-consuming and laborious installation of new liner, and difficulty in installing new liner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

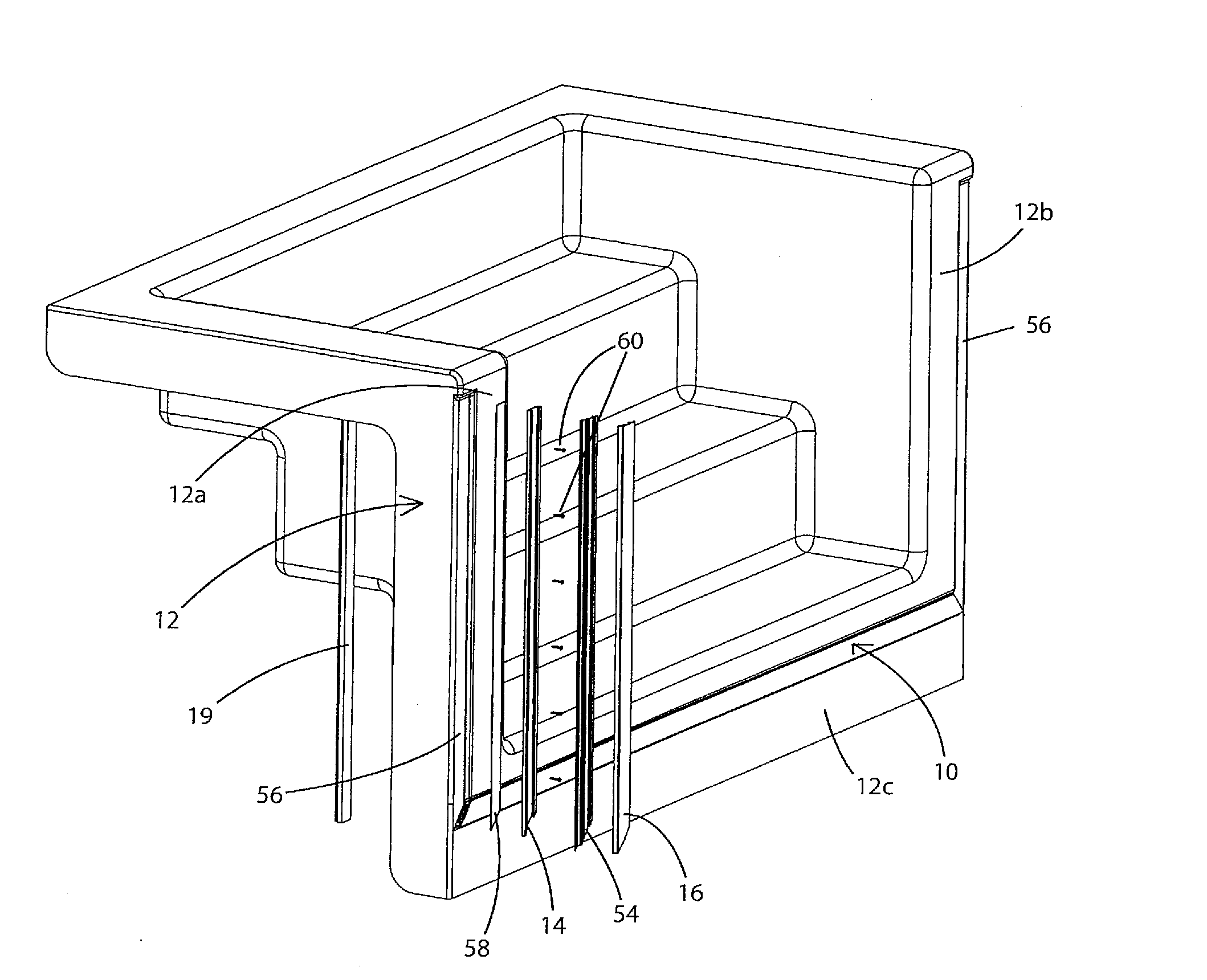

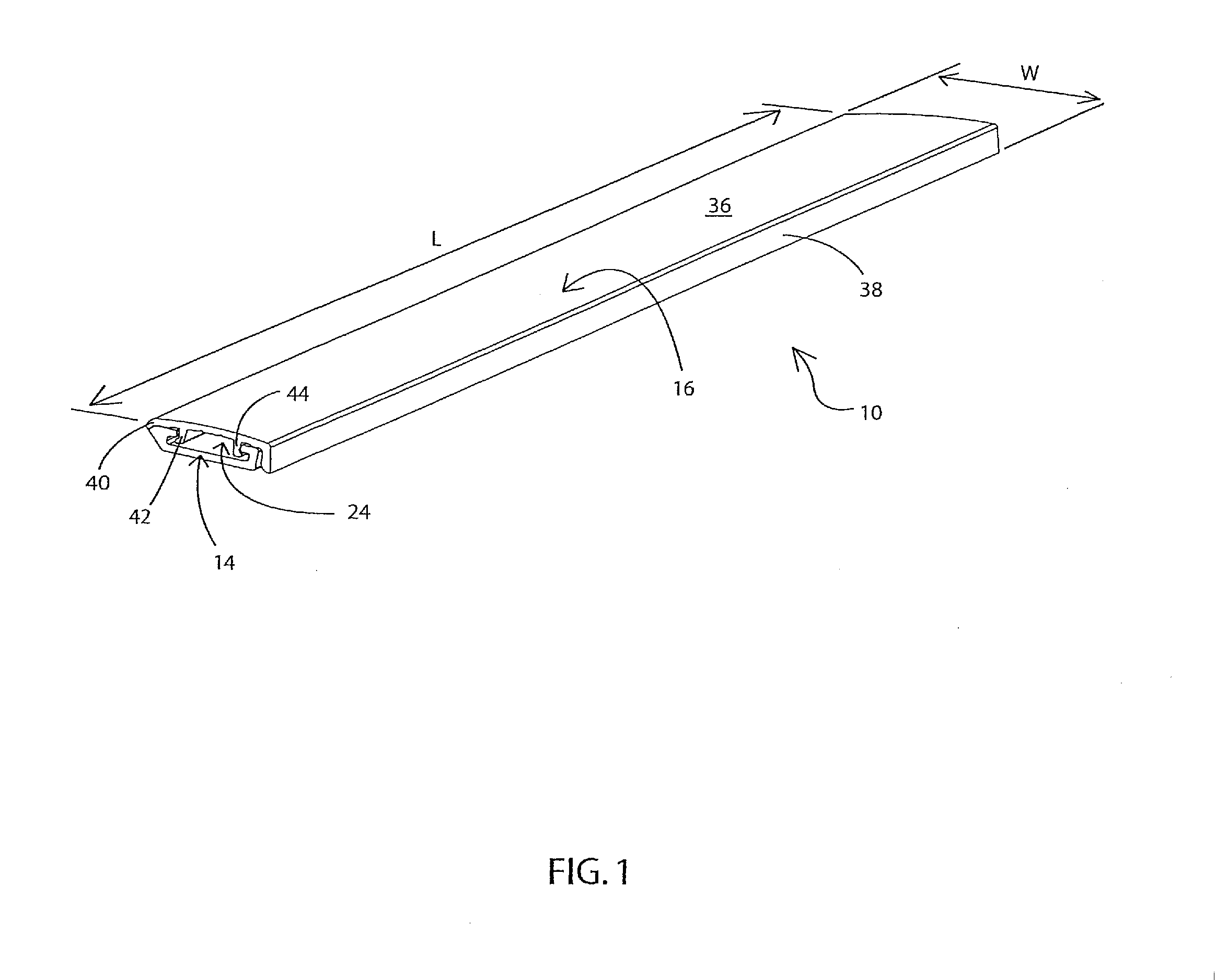

[0045]Referring to FIGS. 1-7, there is shown a sealing member for securing vinyl pool liners to pool fixtures in accordance with the present invention and generally indicated at 10. In particular, this embodiment of the sealing member 10 is designed for use with larger pool fixtures such as stair systems 12 (FIG. 3).

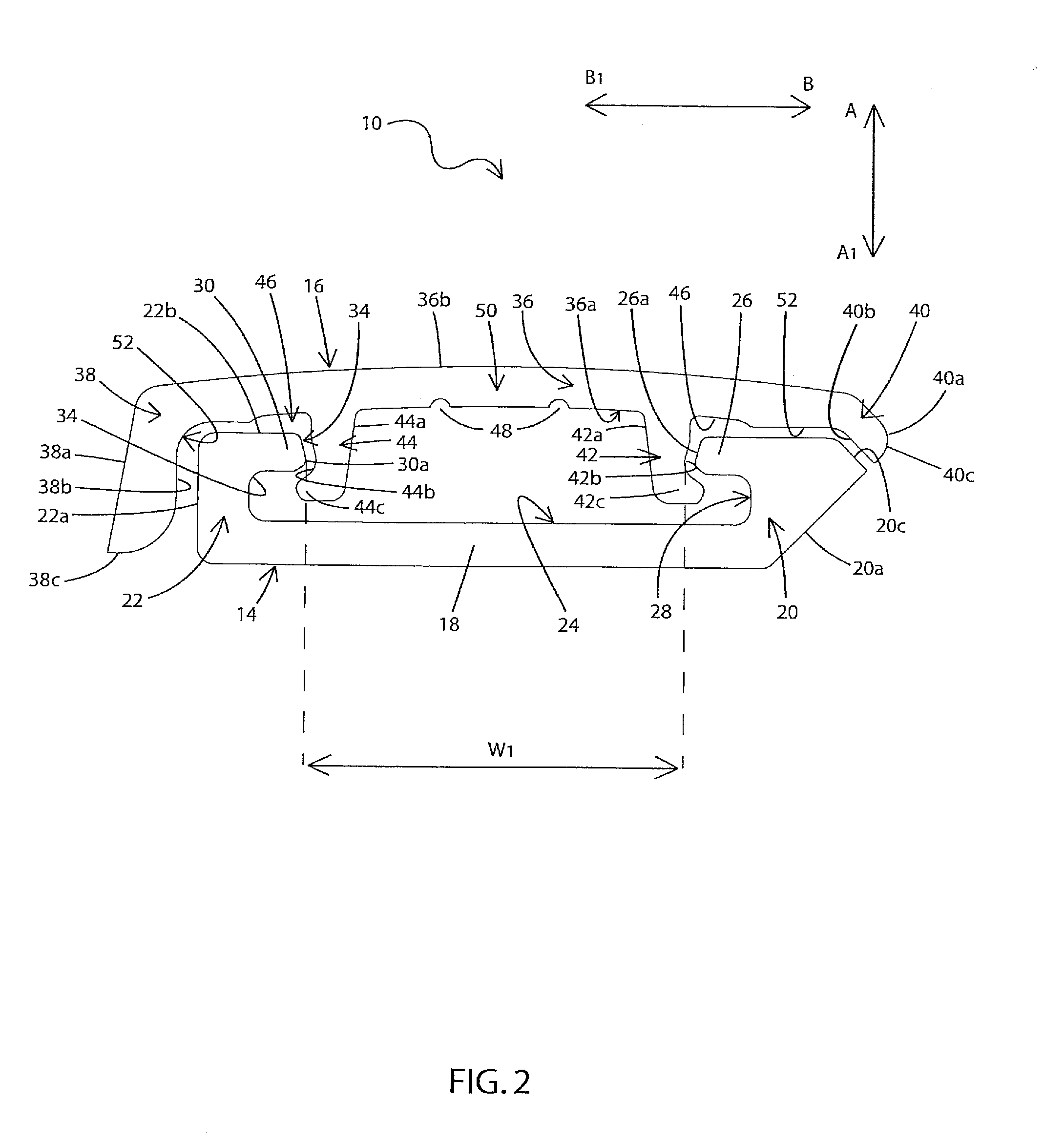

[0046]Sealing member 10 comprises an inner frame member 14 and an outer frame member 16 that are matingly engageable with each other as illustrated in FIG. 2. Inner frame member 14 and outer frame member 16 are both substantially straight, elongated members that have a length “L” and a width “W”. Preferably, inner and outer frame members 14, 16 are manufactured from a substantially rigid plastic or fiberglass and are substantially non-flexing.

[0047]Inner member 14 is generally U-shaped in cross-section and includes a bottom wall 18 with two side walls 20, 22 extend upwardly and outwardly therefrom and defining a channel 24 thereinbetween. Side wall 20 has a first surface...

third embodiment

[0068]Referring to FIGS. 16-21 there is shown a sealing member in accordance with the present invention and generally indicated at 310. The fixtures that are typically installed in pools using vinyl liners are made from plastic or fiberglass. As such, they are molded or cast from the plastic or fiberglass. In accordance with the present invention, sealing member 310 is molded or cast into smaller fixtures such as the drain 380 illustrated in these figures. In these instances, instead of utilizing an inner frame member and outer frame member that are designed to snap fit together, an outer portion of the frame of the fixture itself is designed to snap-fit with an inner portion of the frame. The liner is trapped therebetween in much the same way as was described with reference to the embodiments shown in FIGS. 1-15.

[0069]Drain 380 is therefore provided with a housing 382 molded to include an inner frame member 314. Inner frame member 314 is molded to include an annular channel 324 the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com