Condenser

a technology of condenser and super-cooler, which is applied in the direction of indirect heat exchangers, refrigeration components, lighting and heating apparatus, etc., can solve the problems of inability to achieve the improvement of refrigerant condensation efficiency and super-cooling efficiency, and achieve the effect of increasing the width of the stable rang

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]Embodiments of the present invention will next be described with reference to the drawings.

[0036]In the following description, the reverse side of the sheet on which FIG. 1 is drawn will be referred to as the “front,” and the opposite side as the “rear.”

[0037]The term “aluminum” as used in the following description encompasses aluminum alloys in addition to pure aluminum.

[0038]Like portions and components are denoted by like reference numerals throughout the drawings, and they will not be described redundantly.

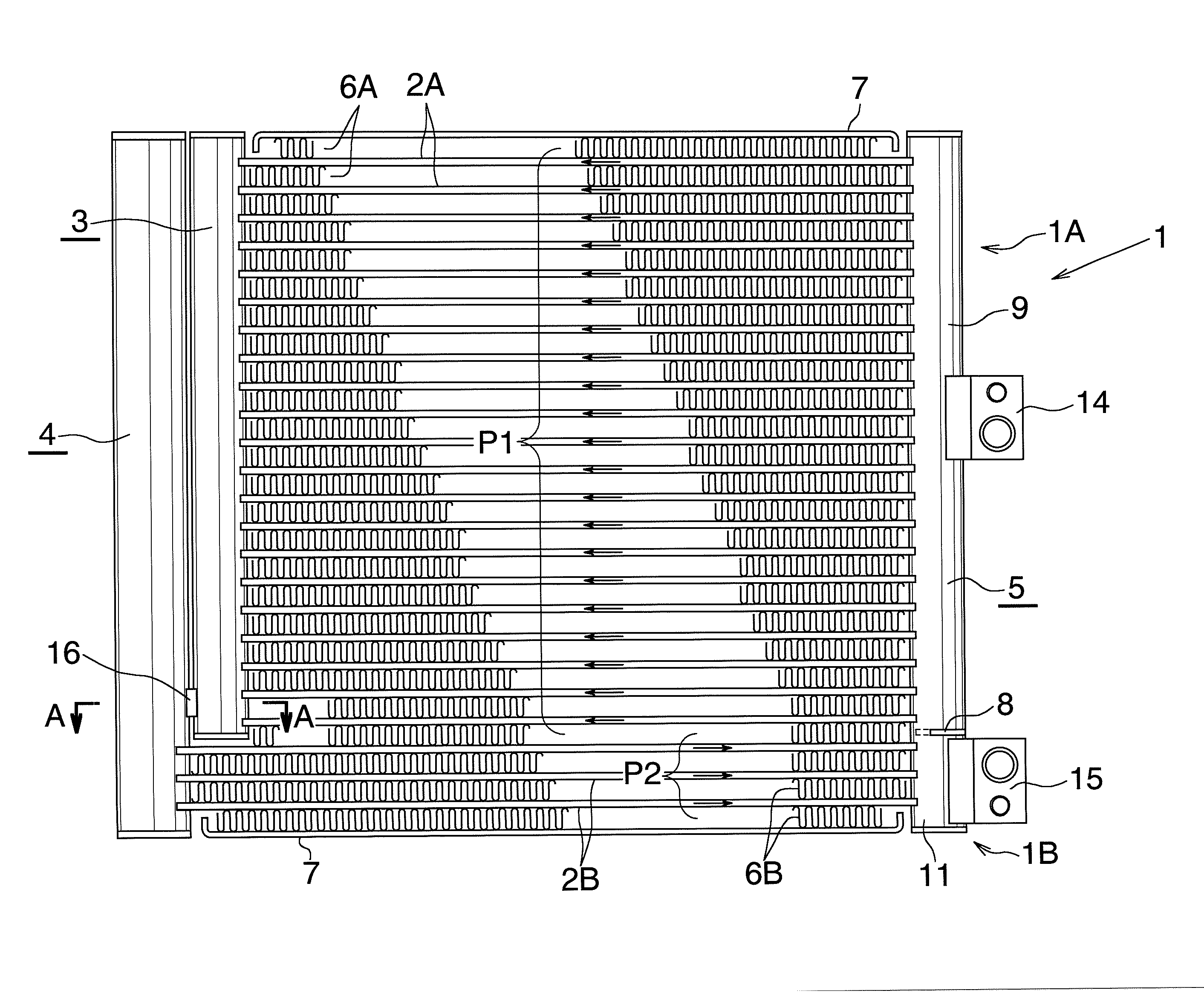

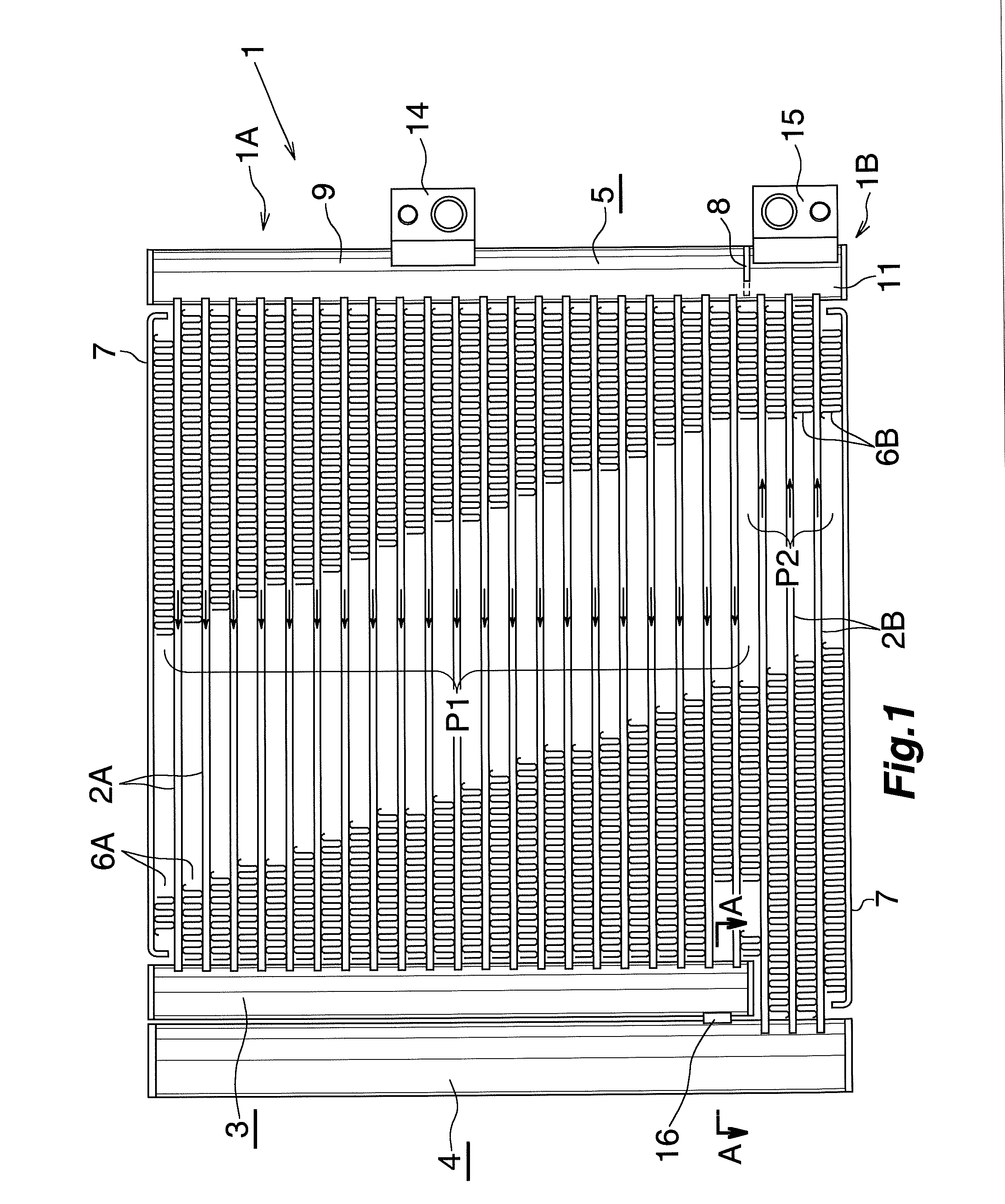

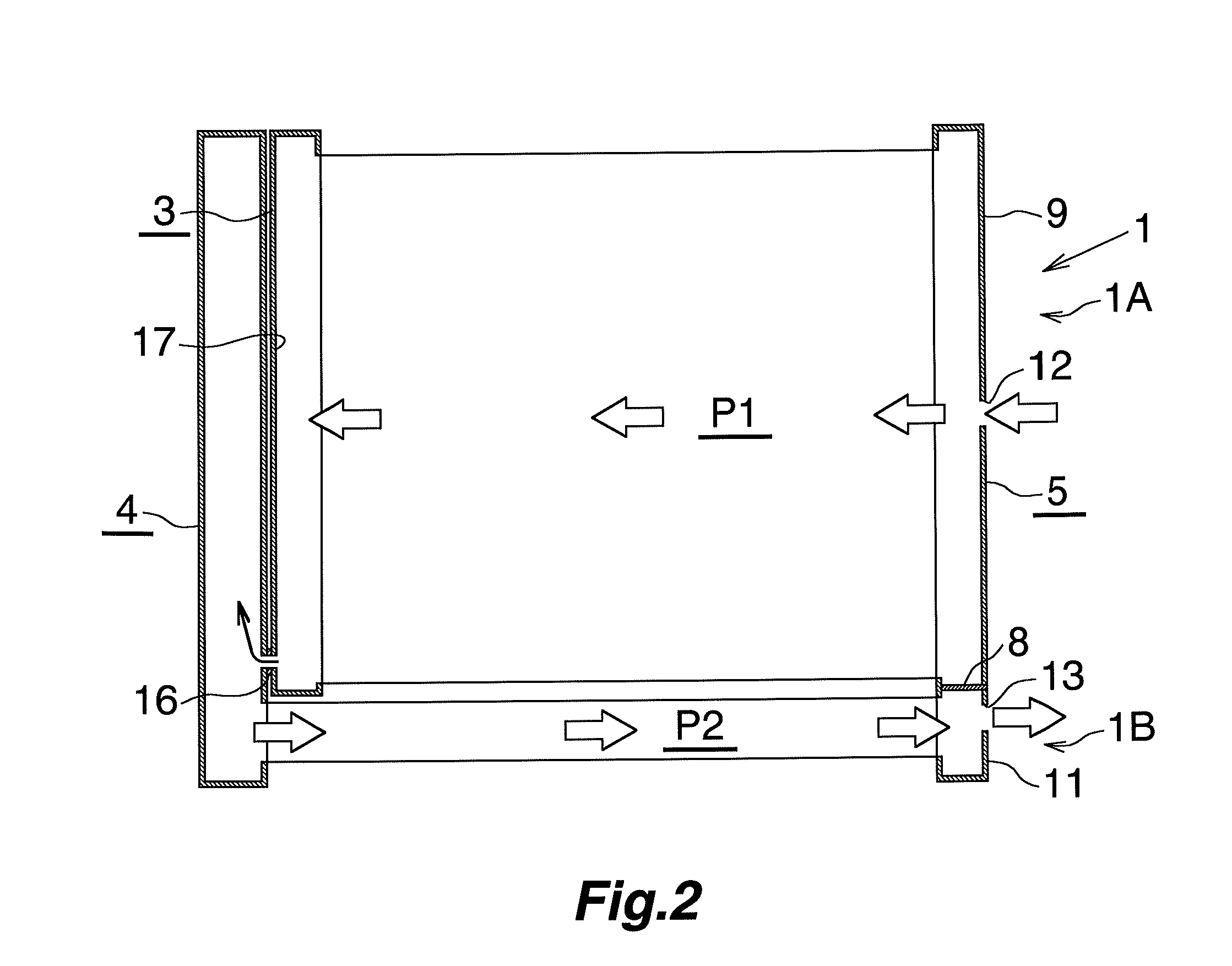

[0039]FIG. 1 specifically shows the overall structure of a first embodiment of a condenser according to the present invention. FIG. 2 schematically shows the condenser of FIG. 1. FIGS. 3 and 4 show the structure of a main portion of the condenser of FIG. 1. In FIG. 2, individual heat exchange tubes are not illustrated, and corrugate fins, side plates, a refrigerant inlet member, and a refrigerant outlet member are also not illustrated.

[0040]In FIGS. 1 and 2, a condenser ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com