Doughtnut-shaped hollow core body, bidirectional hollow core slab using the same, and construction method thereof

a hollow core and doughnut technology, applied in the field of light weight, can solve the problems of low structural resistance of the slab, inability to apply one-way hollow core slabs to buildings, and lack of design changes and additional costs, and achieve the effect of simplifying the arrangement of the slab steel bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

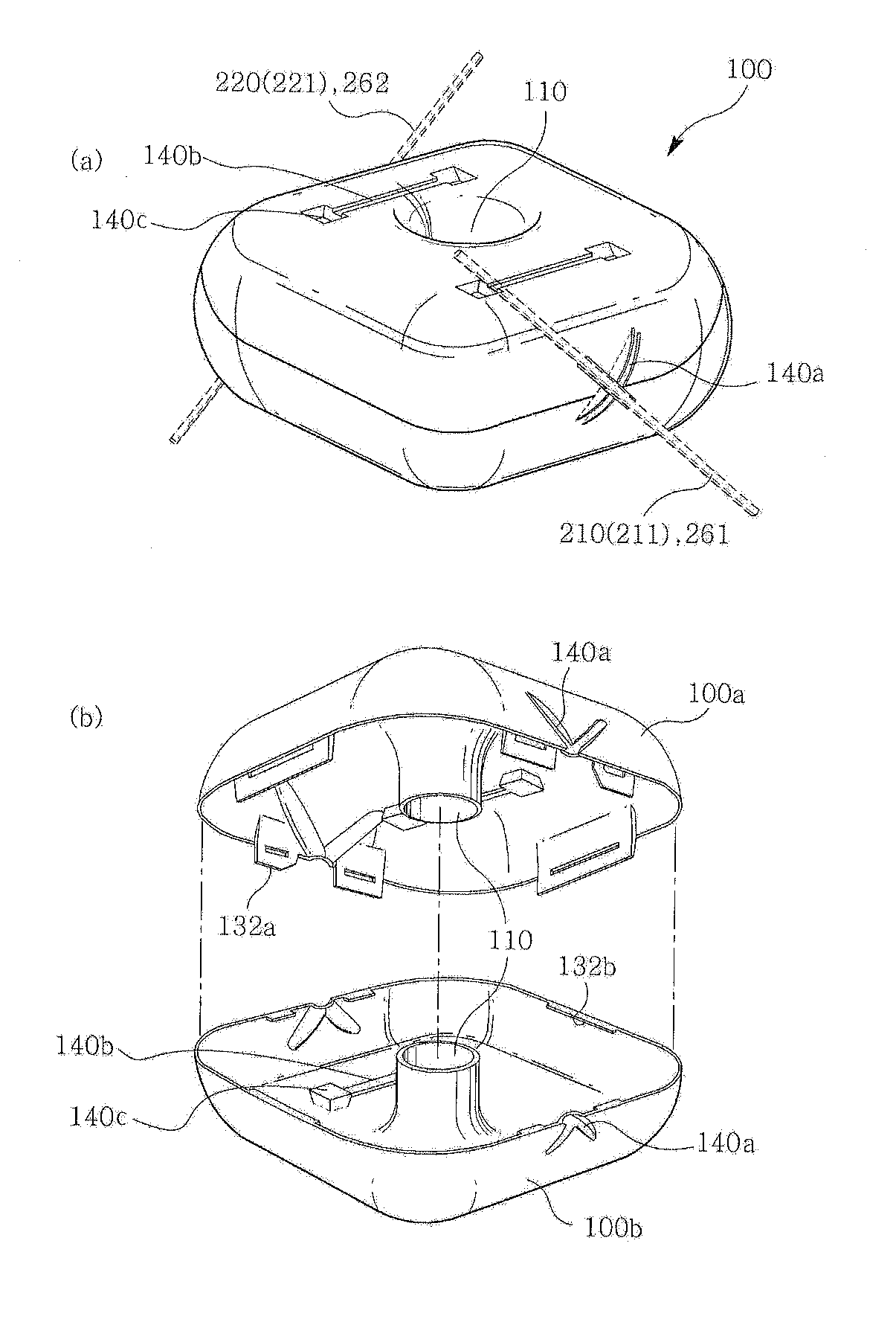

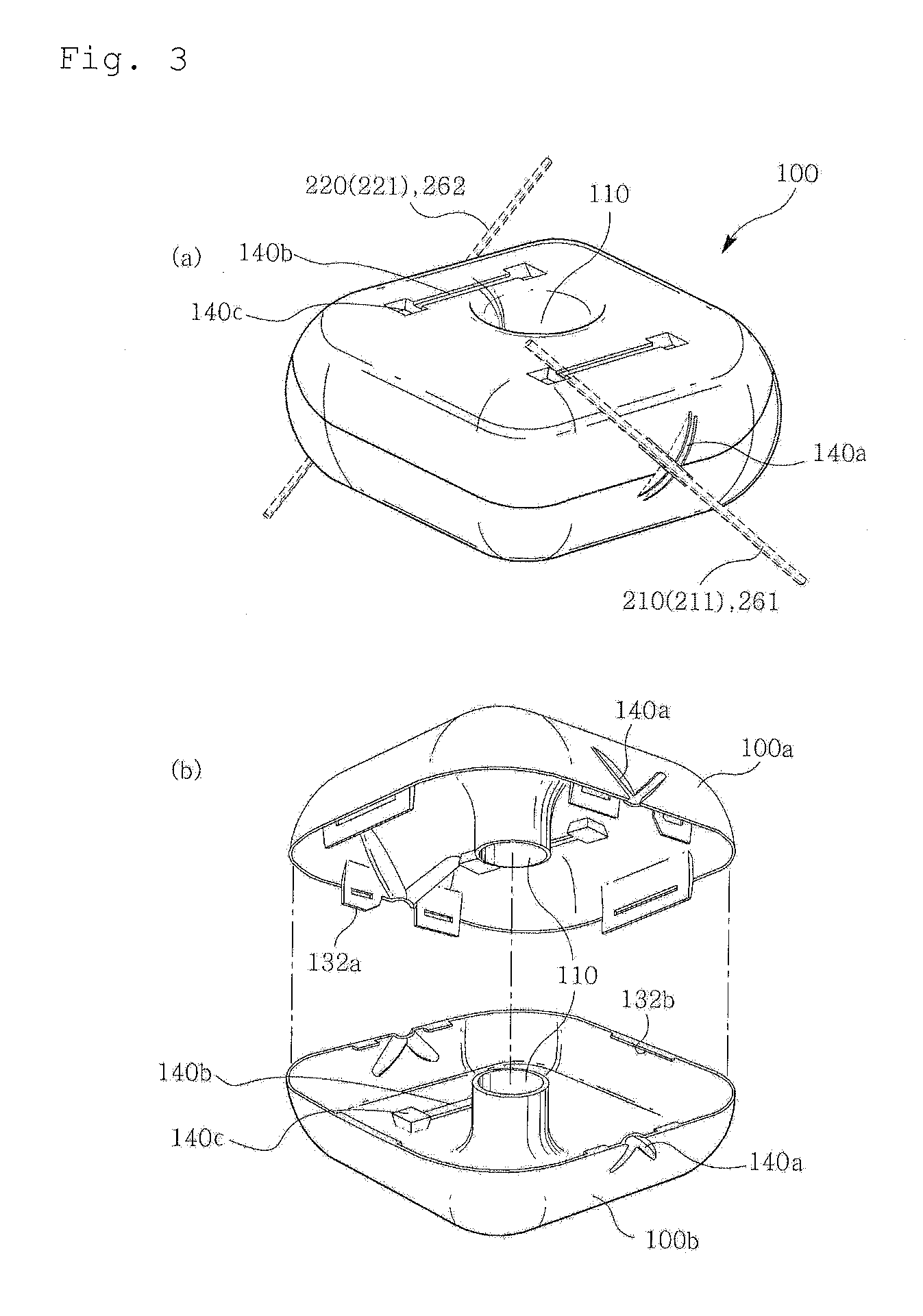

[0025]According to a first aspect of the present invention, there is provided a hollow core body that is adapted to be buried into concrete for the construction of a lightweight concrete member, having a hollow portion with a circular section formed in the center thereof and corners rounded with curved surfaces, thereby providing a generally doughnut-shaped outer case.

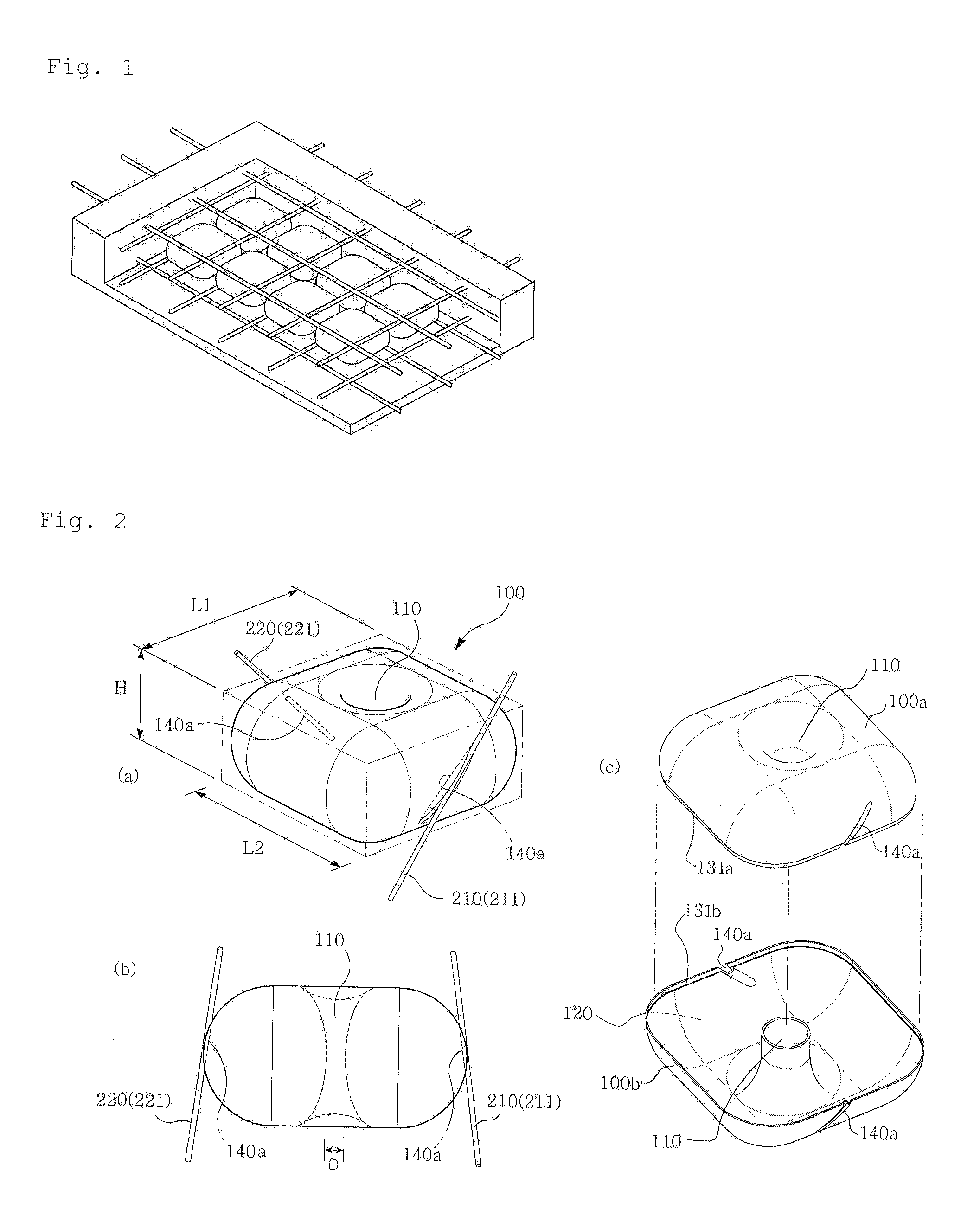

[0026]According to a second aspect of the present invention, there is provided a bidirectional hollow core slab including:

[0027]steel bar cages each having first and second side bent bars, an upper bent bar, and first and second end tilt bars; doughnut-shaped hollow core bodies spacedly arranged in rows and columns in such a manner as to be restrained in the steel bar cages by means of fitting slots formed on both sides facing each other; slab lower steel bars arranged beneath the steel bar cages; slab upper steel bars arranged on the steel bar cages; and slab concrete cast and cured to a thickness through which the sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com