Inner tube having a reinforced core member structure for ball sports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]The various objects and advantages of the present invention will be more readily understood from the following detailed description of four embodiments when read in conjunction with the appended drawings, in which like reference numbers denote like elements of structure.

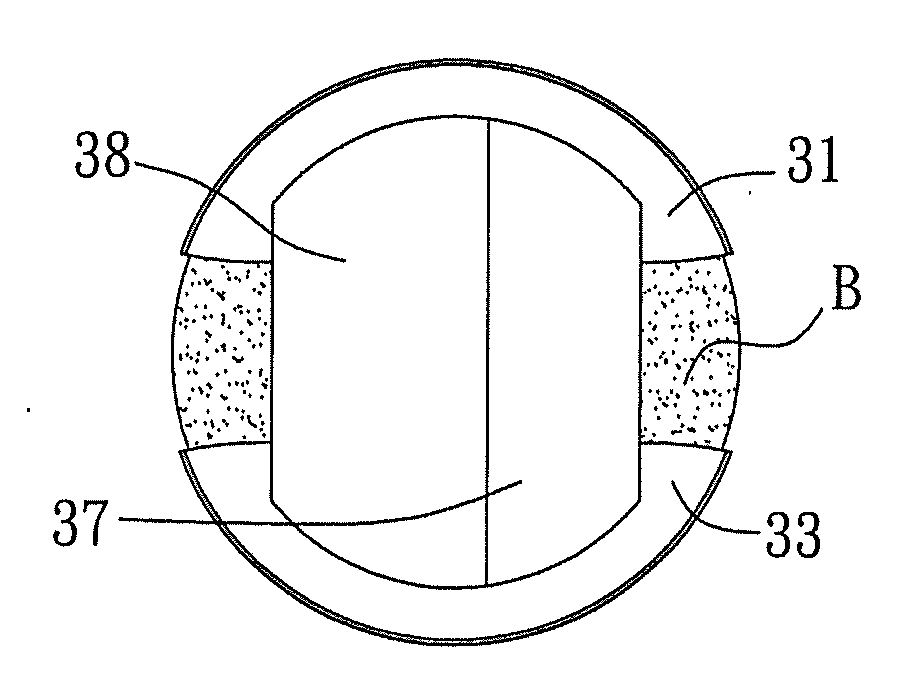

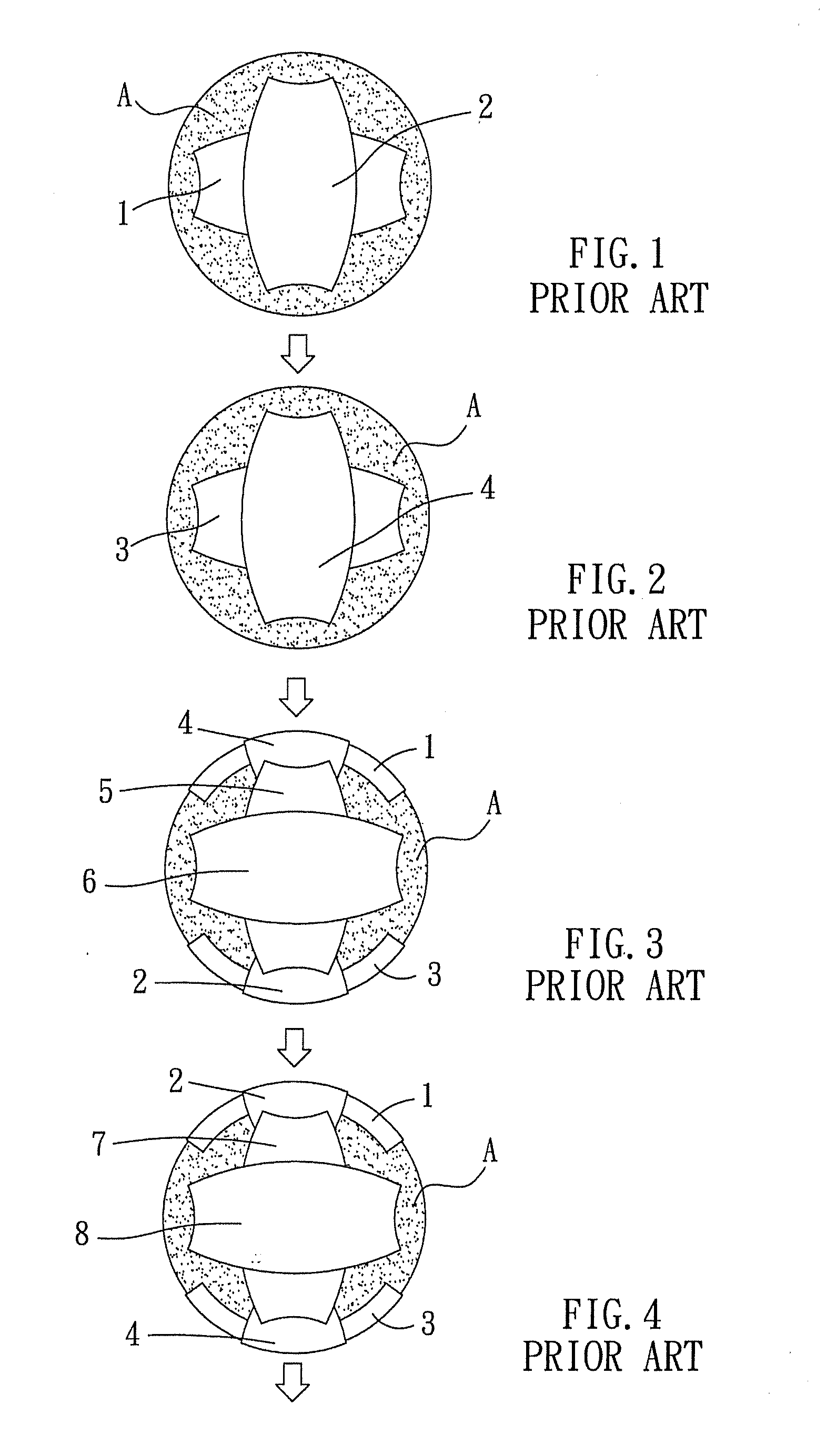

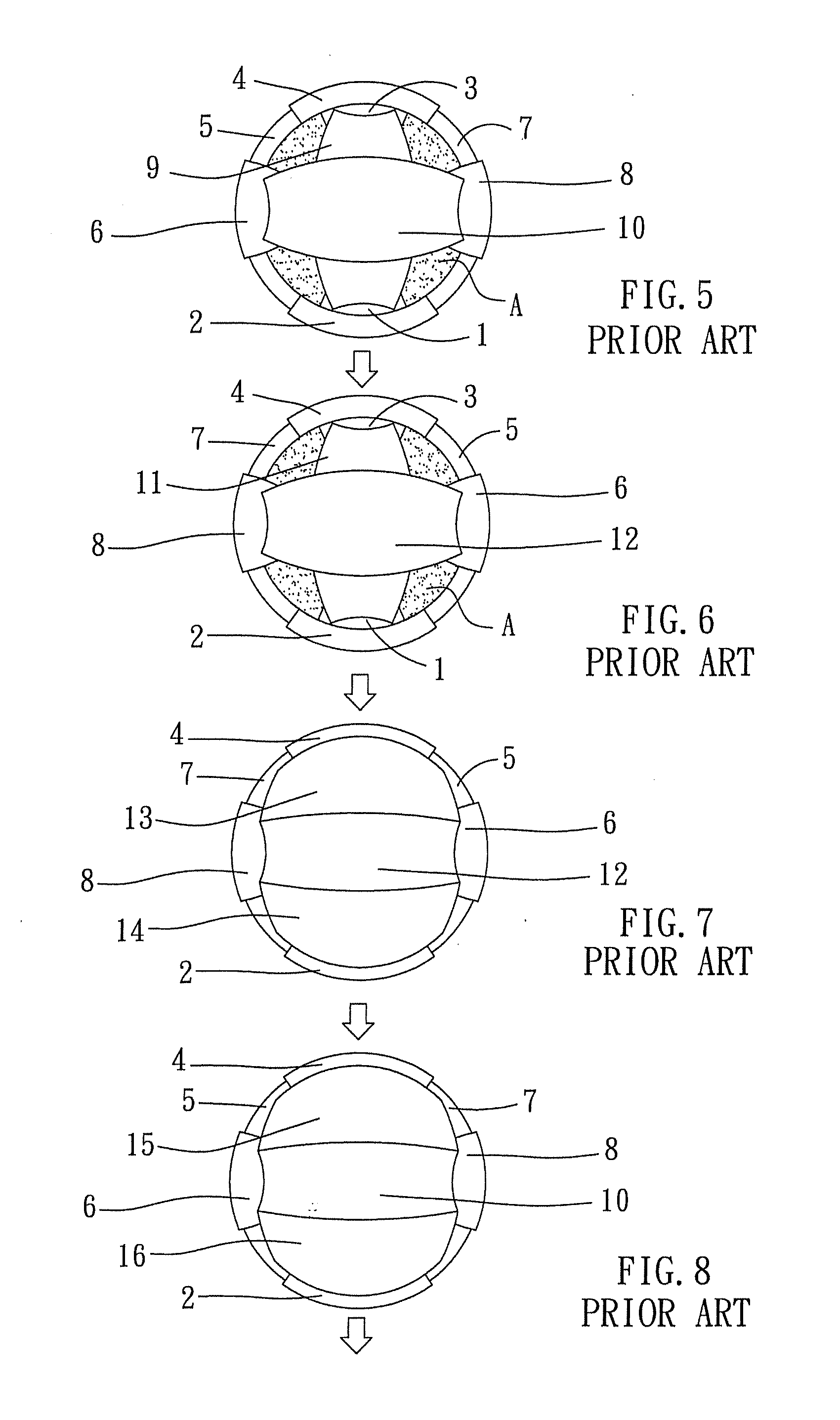

[0037]Referring to FIGS. 12˜23, an inner tube having a reinforced core member structure for ball sports in accordance with the present invention is shown comprising a spherical rubber body B, four first paper strips arranged into two abutted parallel pairs 31,32;33,34 and respectively bonded to the front side (see FIG. 12) and back side (see FIG. 13) of the spherical rubber body B with latex adhesive, four second paper strips arranged into two abutted parallel pairs 35,36;37,38 and respectively bonded to the top side (see FIG. 14) and bottom side (see FIG. 15) of the spherical rubber body B with latex adhesive and respectively partially overlapped on the ends of the first paper strips 31˜34, four third paper st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com