Anchoring device

a technology of an anchoring device and a ring, which is applied in the direction of rod connections, couplings, mechanical apparatuses, etc., can solve the problems of additional components, additional components, and the need to hold the shell halves or wedges together by additional components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

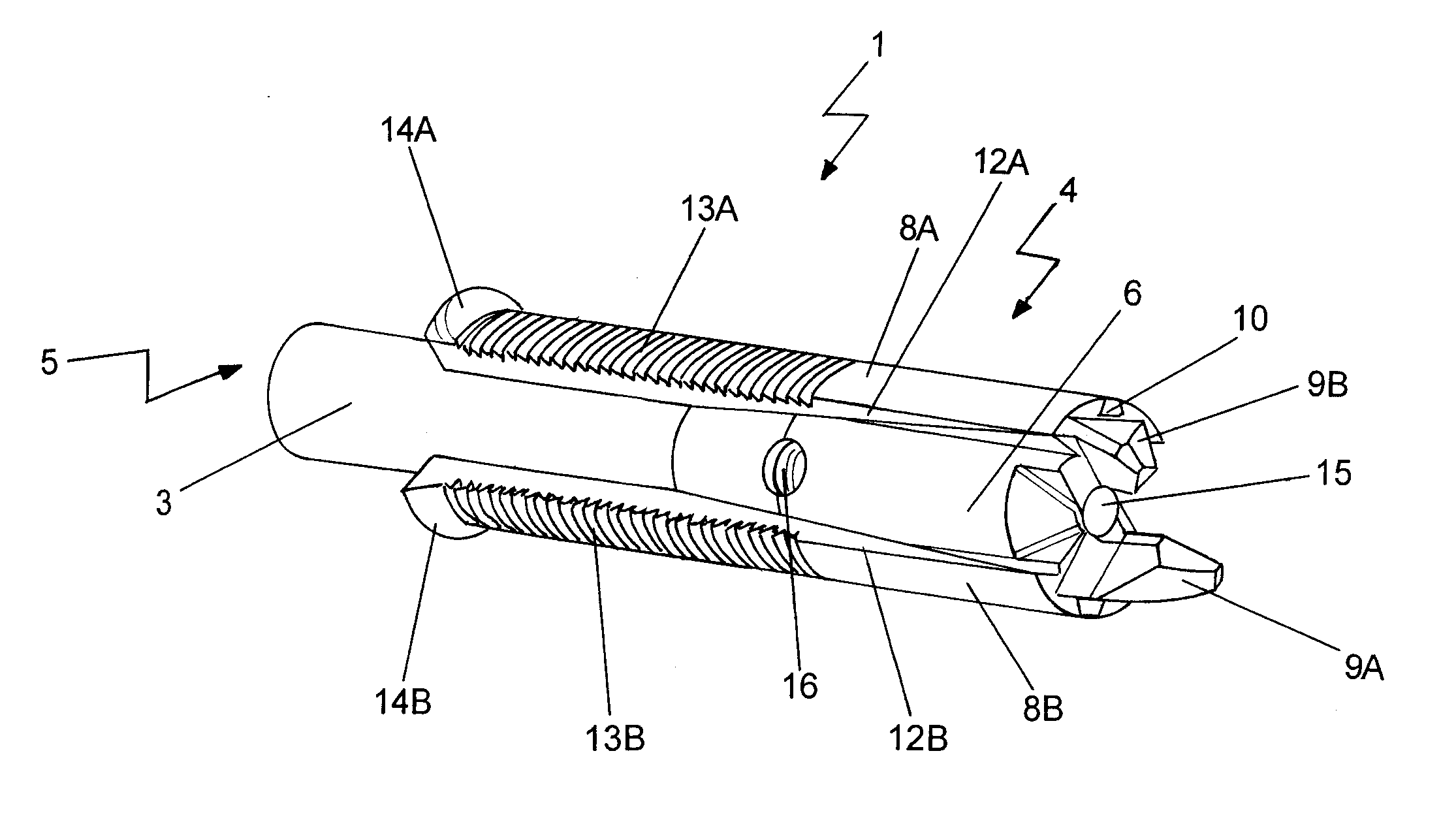

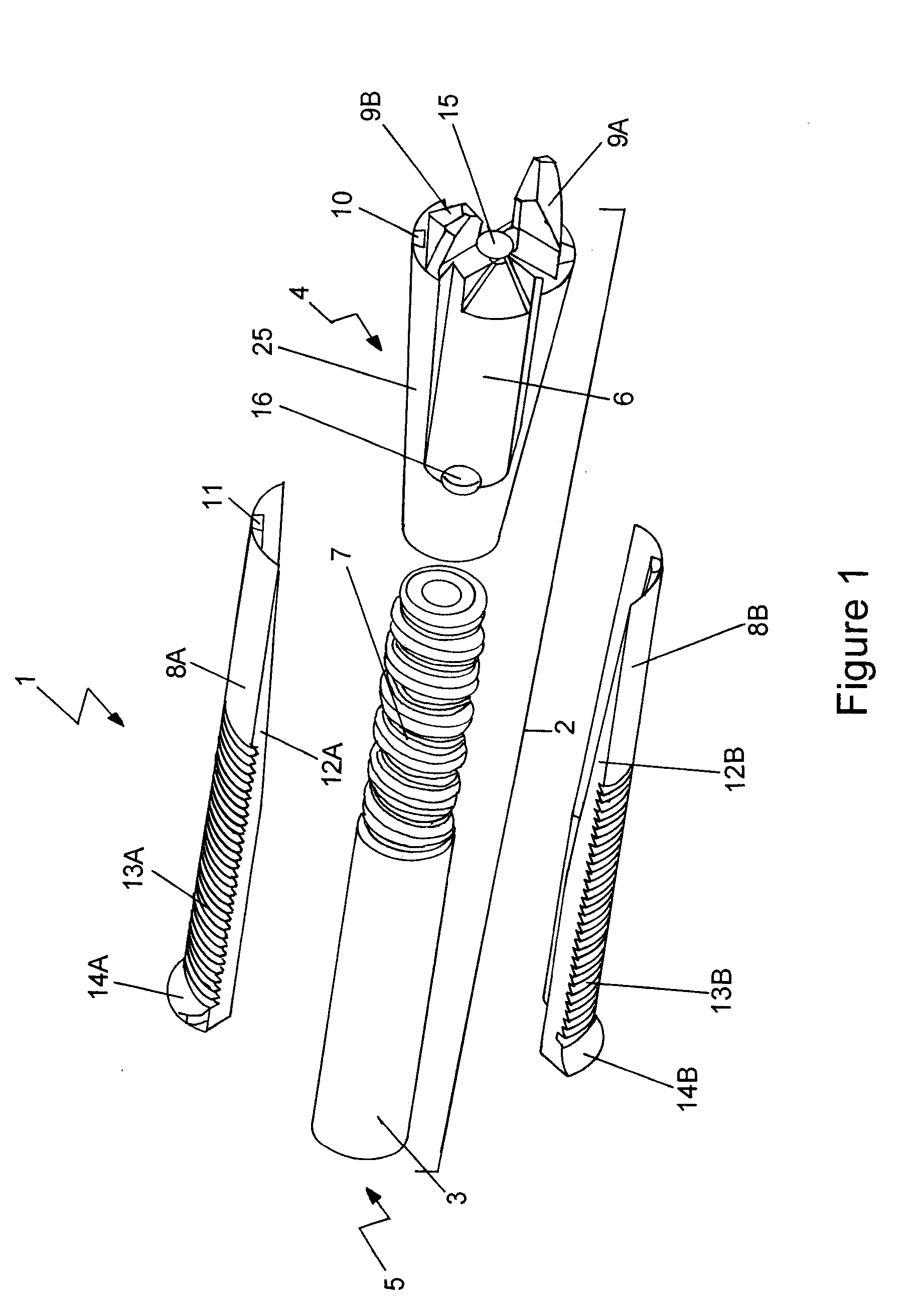

[0108]FIG. 1 shows a preferred embodiment of an anchoring device in the form of a rock bolt (1) of the present invention in its unassembled form.

[0109]Rock bolt (1) incorporates a drilling assembly (2) which includes an elongate shaft (3) with a first (drilling) end (4) and a second (drive) end (5), a drill head (6) at the first end (4), and the second end (5) being configured for connection to a drilling apparatus (not shown) in known fashion.

[0110]The shaft (3), which is typically manufactured from steel, is a hollow tube and incorporates a left hand thread (7) along a length of the shaft (3). For clarity, part of the shaft (3) in FIG. 1 is shown without the thread.

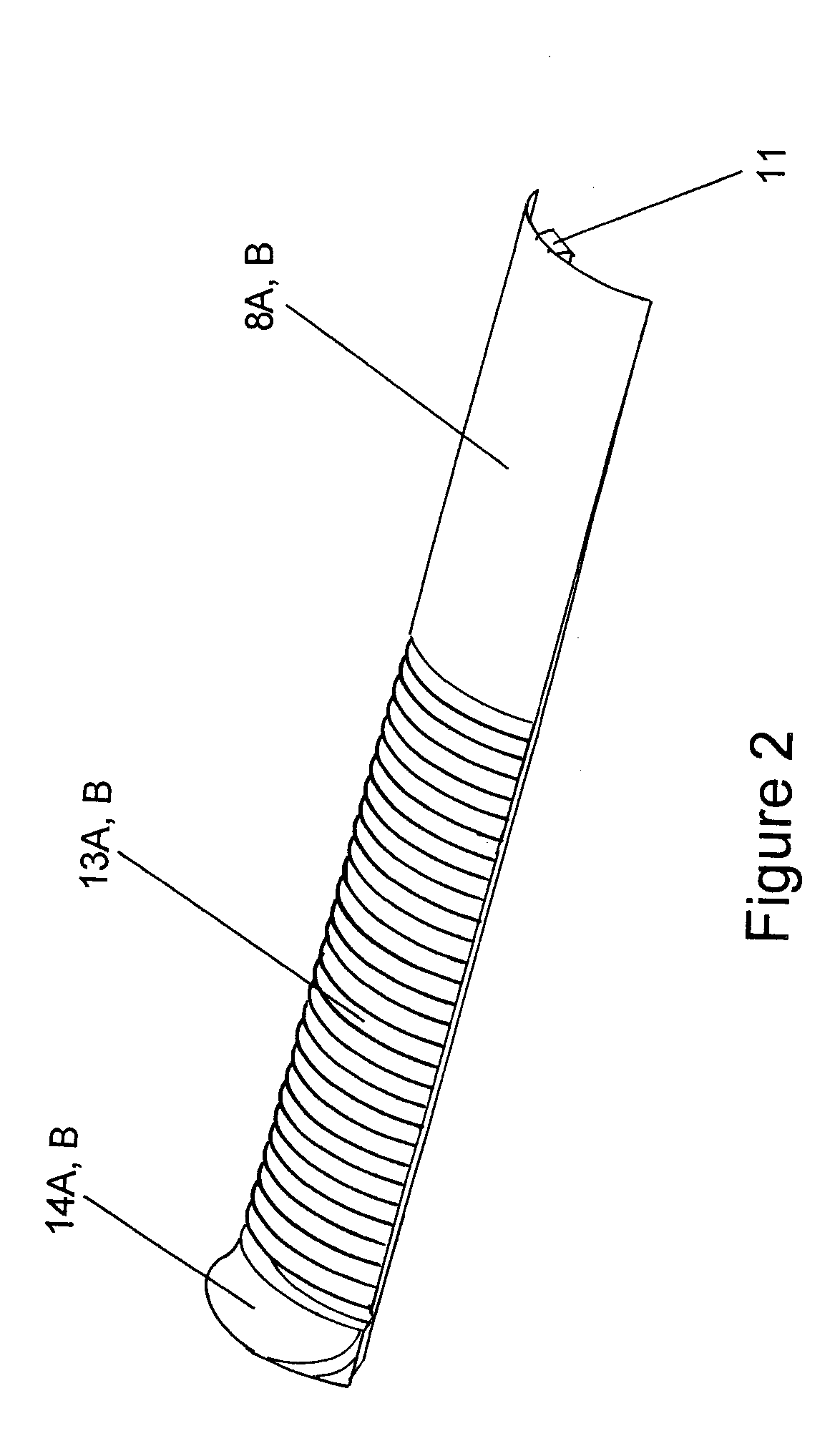

[0111]The rock bolt (1) includes expansion elements or wedges (8A, 8B). For ease of reference the expansion elements (8A, 8B) will now simply be referred to as “wedges” throughout this specification.

[0112]Wedges

[0113]With reference to FIGS. 1, 2 and 3, the wedges (8A, 8B) include ridges (13A, 13B) on the upper surface w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com