Floor tool for a vacuum cleaning appliance

a vacuum cleaning and floor tool technology, applied in the field of floor tools, can solve the problems of affecting the pick-up performance of such tools on hard floors, less accomplished at removing other forms of dirt, etc., and achieve the effect of improving the debris pickup performance of the floor tool and low profil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

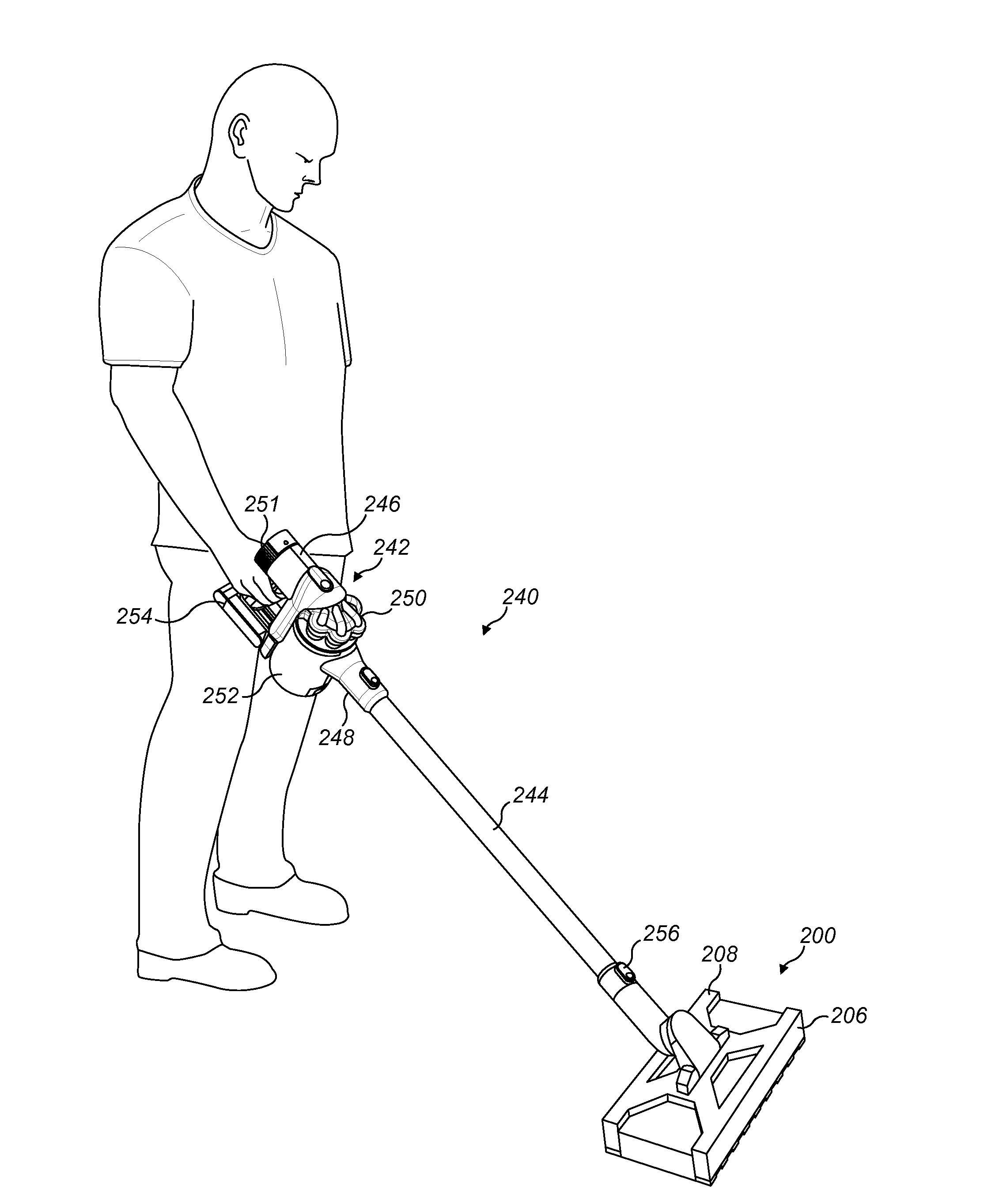

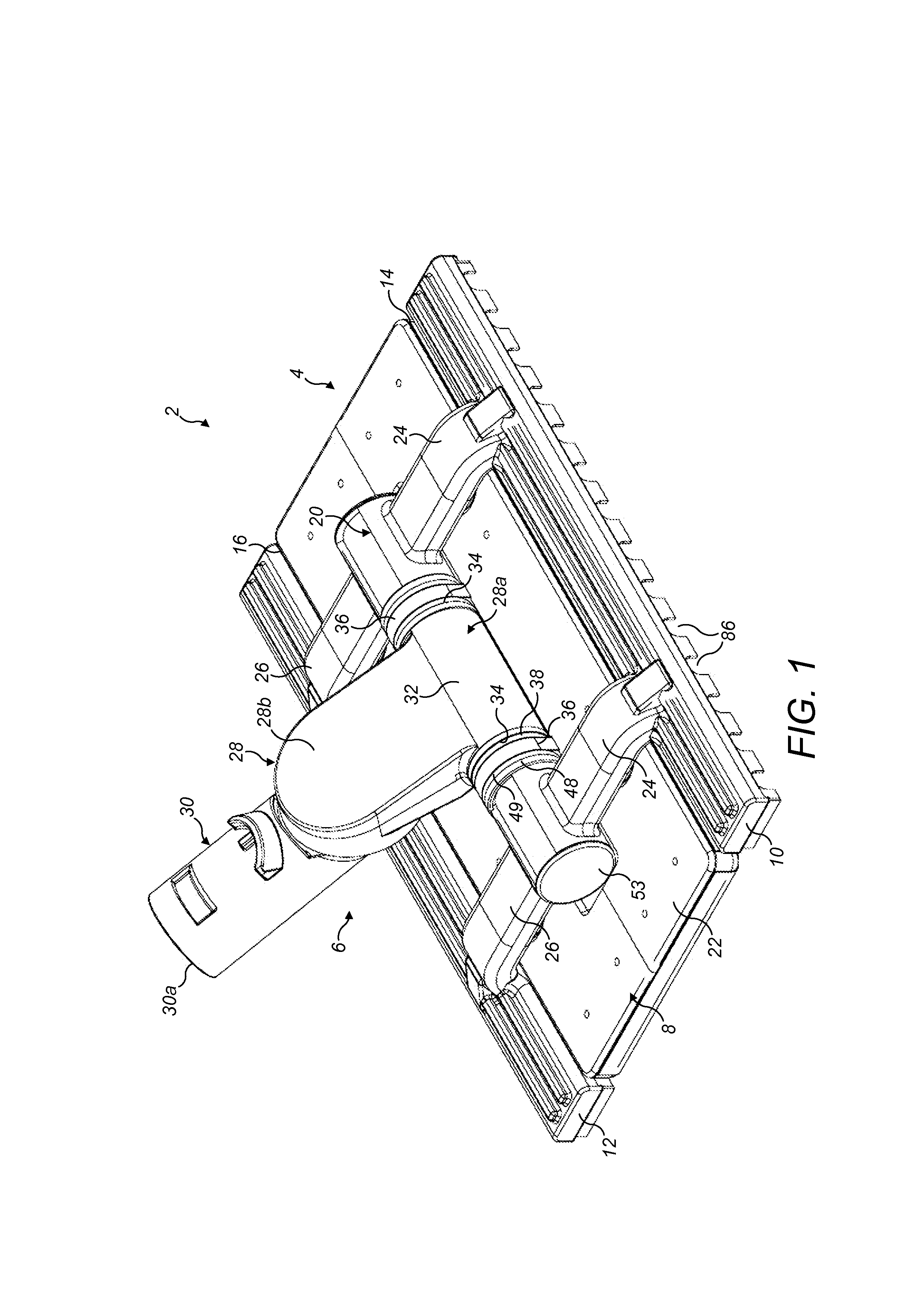

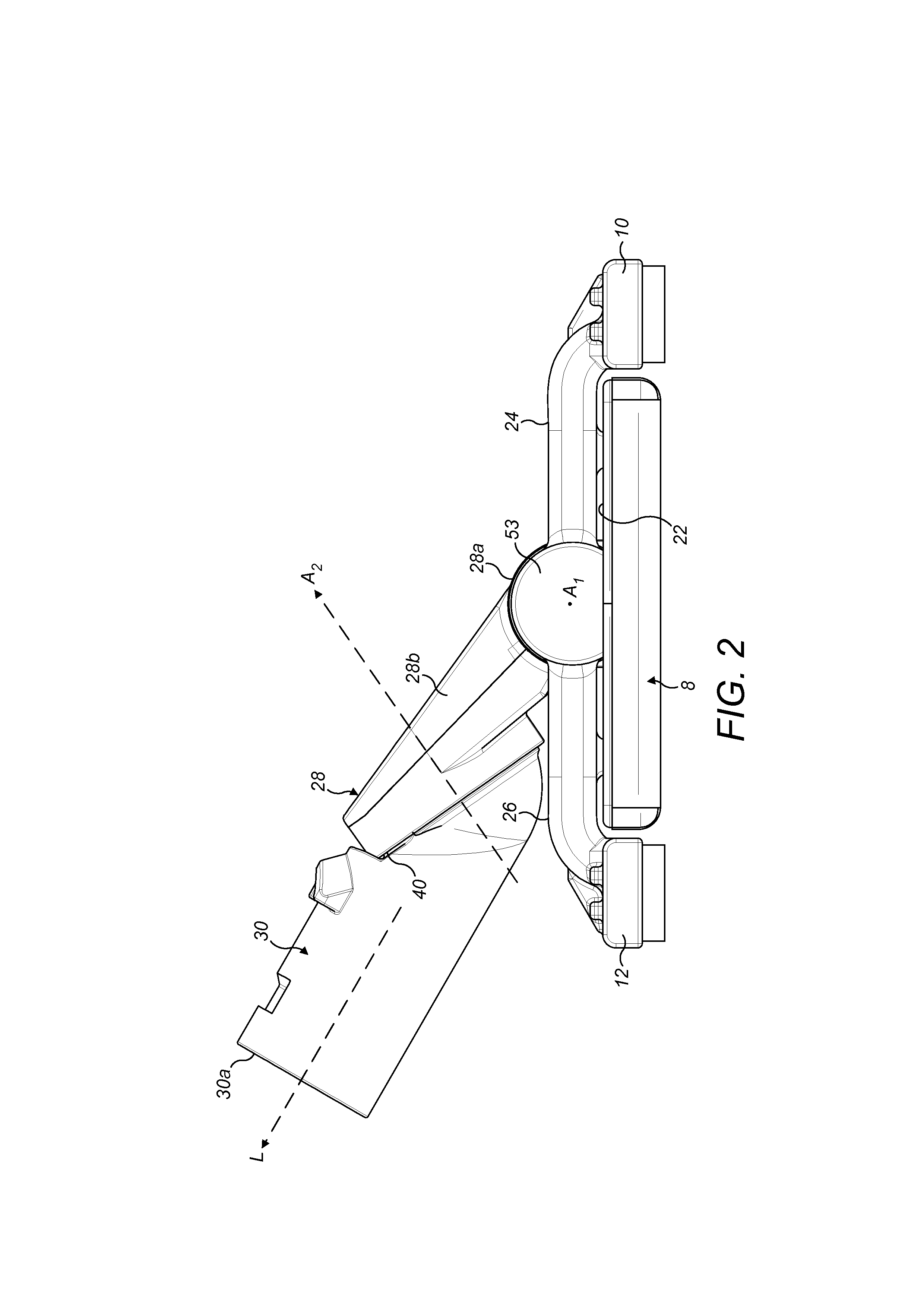

[0047]With reference in general to FIGS. 1 to 6, a floor tool 2 comprises a main body 4 and a conduit 6 associated with the main body 4 which serves to connect the floor tool 2 to a wand of a vacuum cleaner (not shown) and enables a user to manoeuvre the floor tool 2 across a surface to be cleaned.

[0048]The main body 4 comprises a generally oblong support member 8 on which can be carried a sheet-like cleaning element (shown in FIGS. 4 and 5), and first and second suction nozzles 10, 12 arranged adjacent respective long edges 14, 16 of the support member 8. Each of the suction nozzles 10, 12 is pivotably associated with an air manifold 20 that is mounted to an upper surface 22 of the support member 8. In the figures, the floor tool 2 is oriented such that its ‘front’ is facing towards the right hand side of the drawing. Therefore, the first and second suction nozzles 10, 12 can be considered to be a front suction nozzle 10 and a rear suction nozzle 12, respectively, and shall be refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com