Pole-slip protection system and method for synchronous machines

a protection system and synchronous machine technology, applied in the direction of electric motor control, generator circuit arrangement control, electric generator control, etc., can solve problems such as unstable machine arrangemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

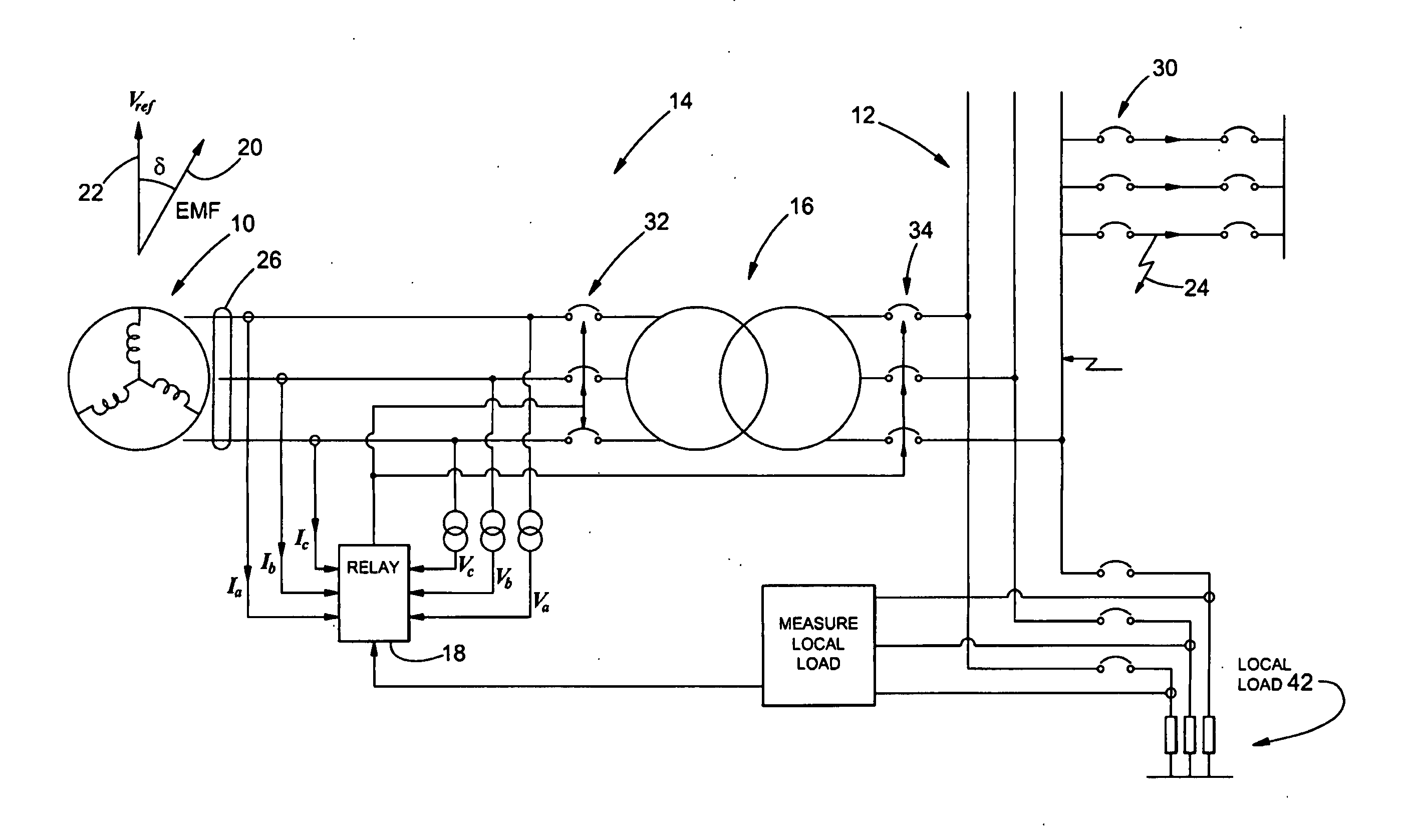

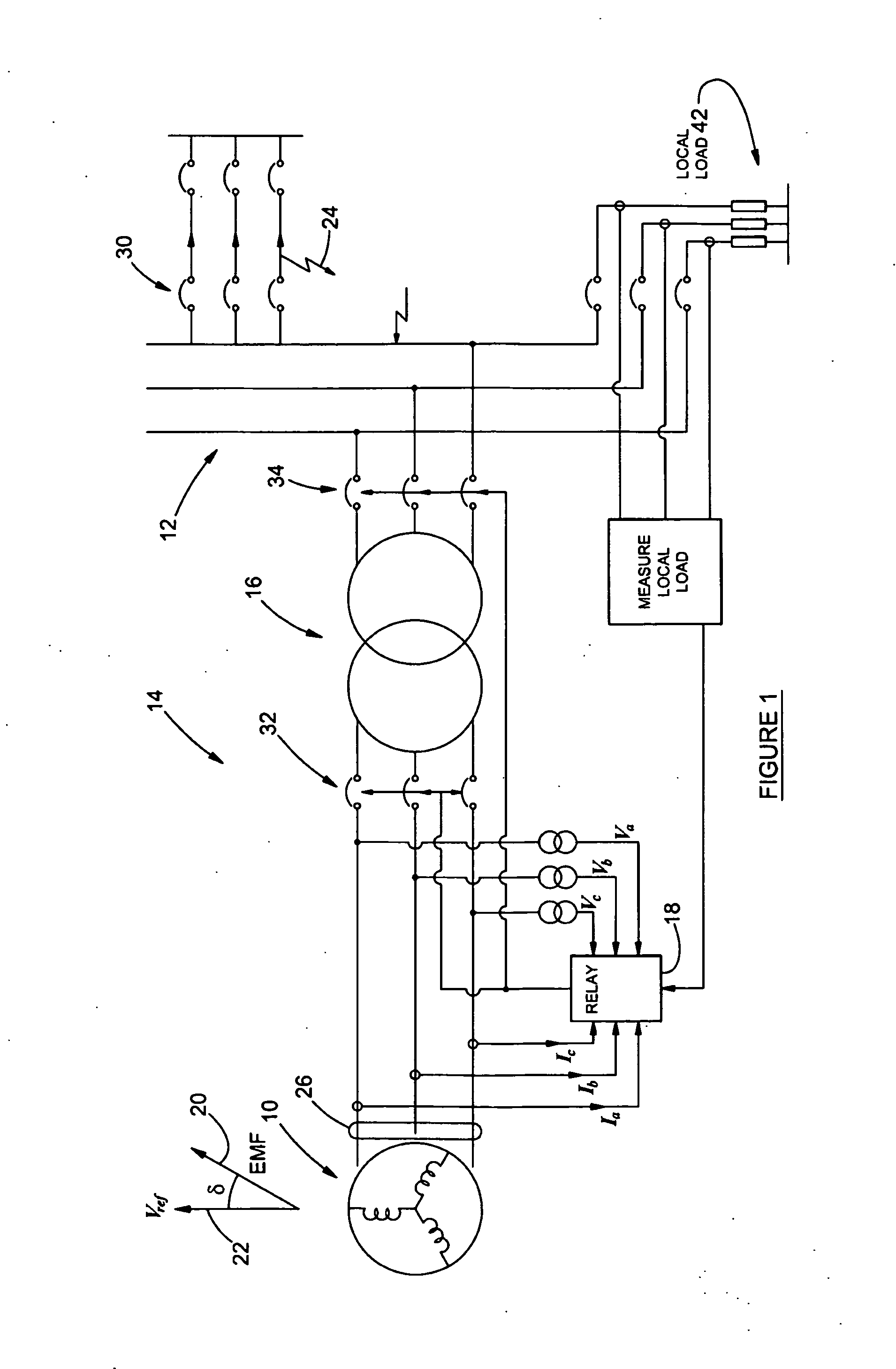

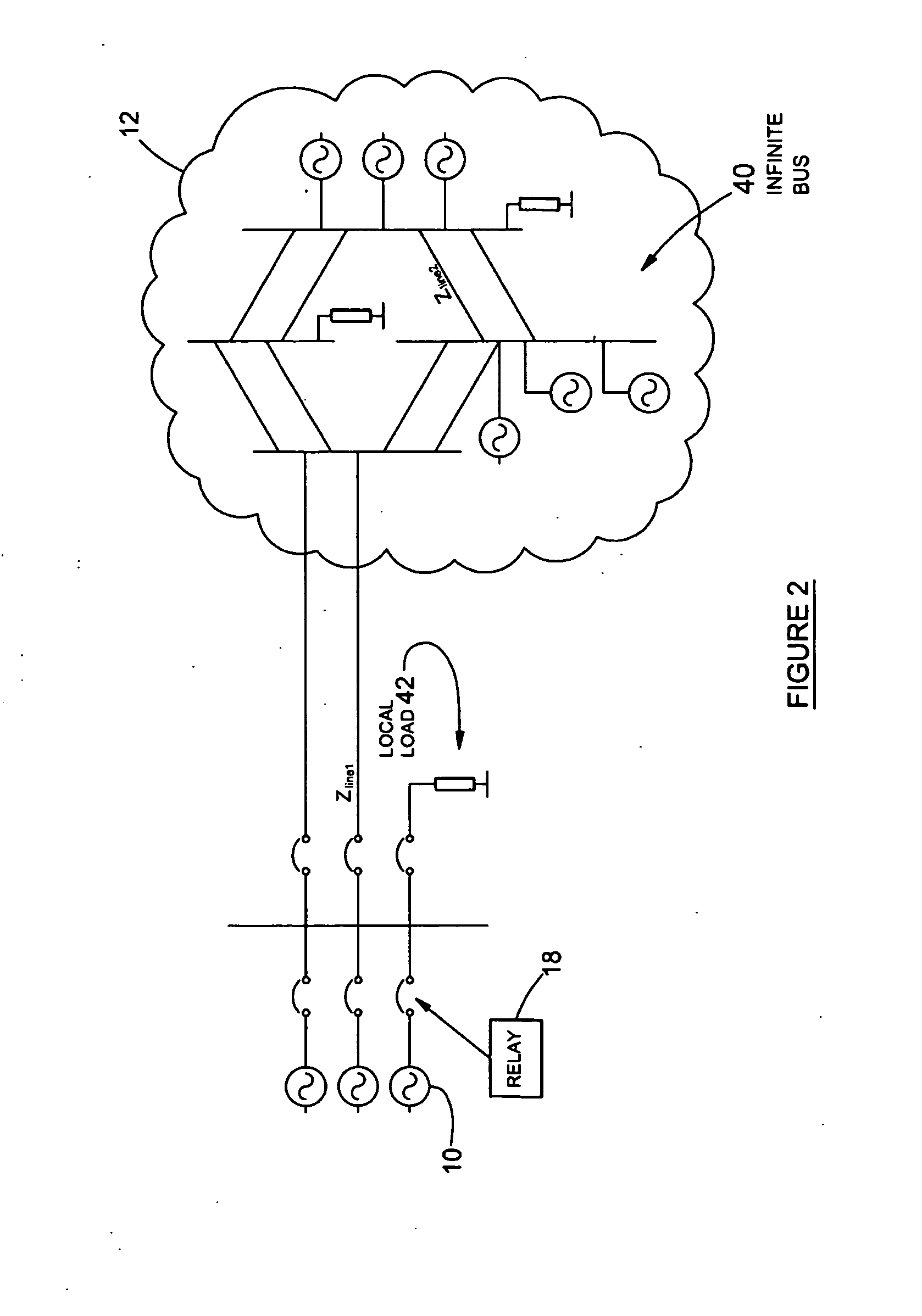

[0047]Referring to FIGS. 1 and 2, there is shown a synchronous rotating machine in the form of a power generator 10 connected to an electricity network 12. The machine 10 forms part of a machine arrangement 14 also comprising an associated transformer 16.

[0048]A computerized protection relay 18 comprises a controller comprising a processor and an associated memory arrangement. The processor is configured to execute a pole-slip detection and protection application program comprising a program code for performing a method of protecting the synchronous machine arrangement against pole-slip as will hereinafter be described.

[0049]The method comprises the steps of the relay 18 continuously computing and monitoring a first variable parameter relating to the machine arrangement with reference to a reference value. In this example embodiment, the first parameter is a power transfer angle (δ) between an electromotive force (EMF) 20 of the machine 10 and a reference voltage (Vref) 22. In the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com