Glow plug

a technology of glow plugs and o-rings, which is applied in the direction of incandescent ignition, combustion process, lighting and heating apparatus, etc., can solve the problems of difficulty in providing a space for accepting deformation of compressed o-rings, failure to ensure gastightness, and breakage of o-rings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

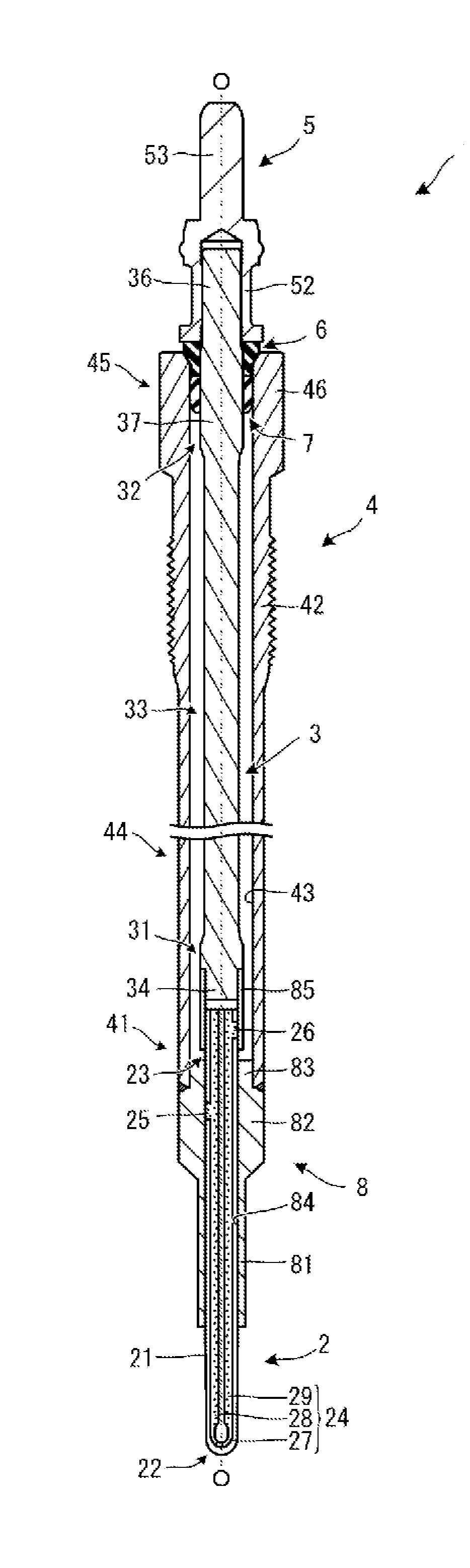

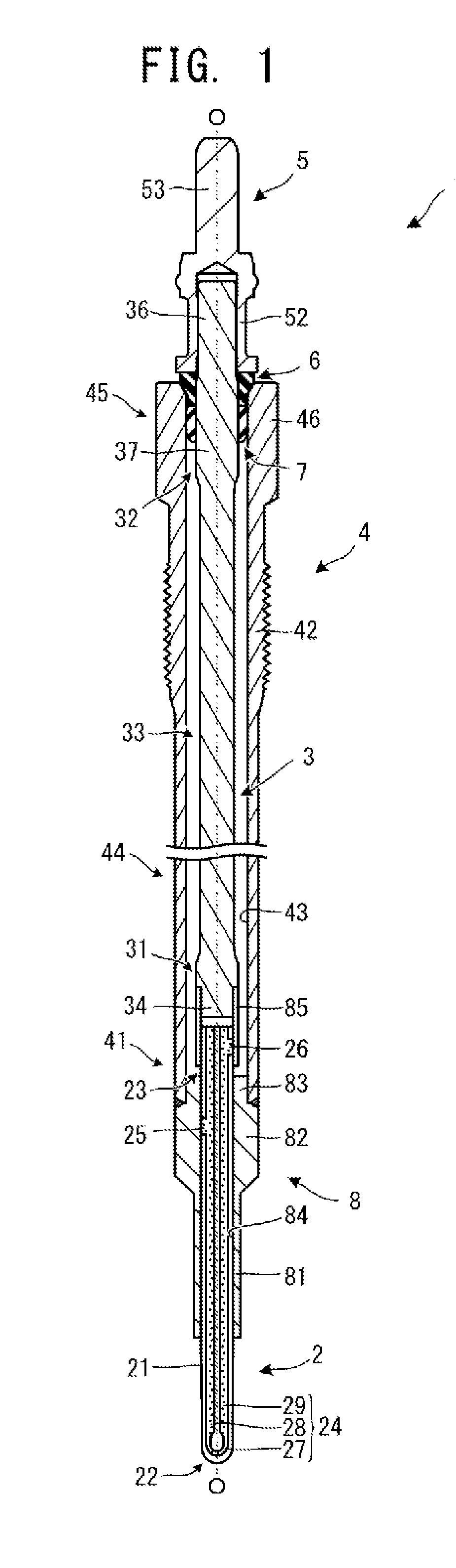

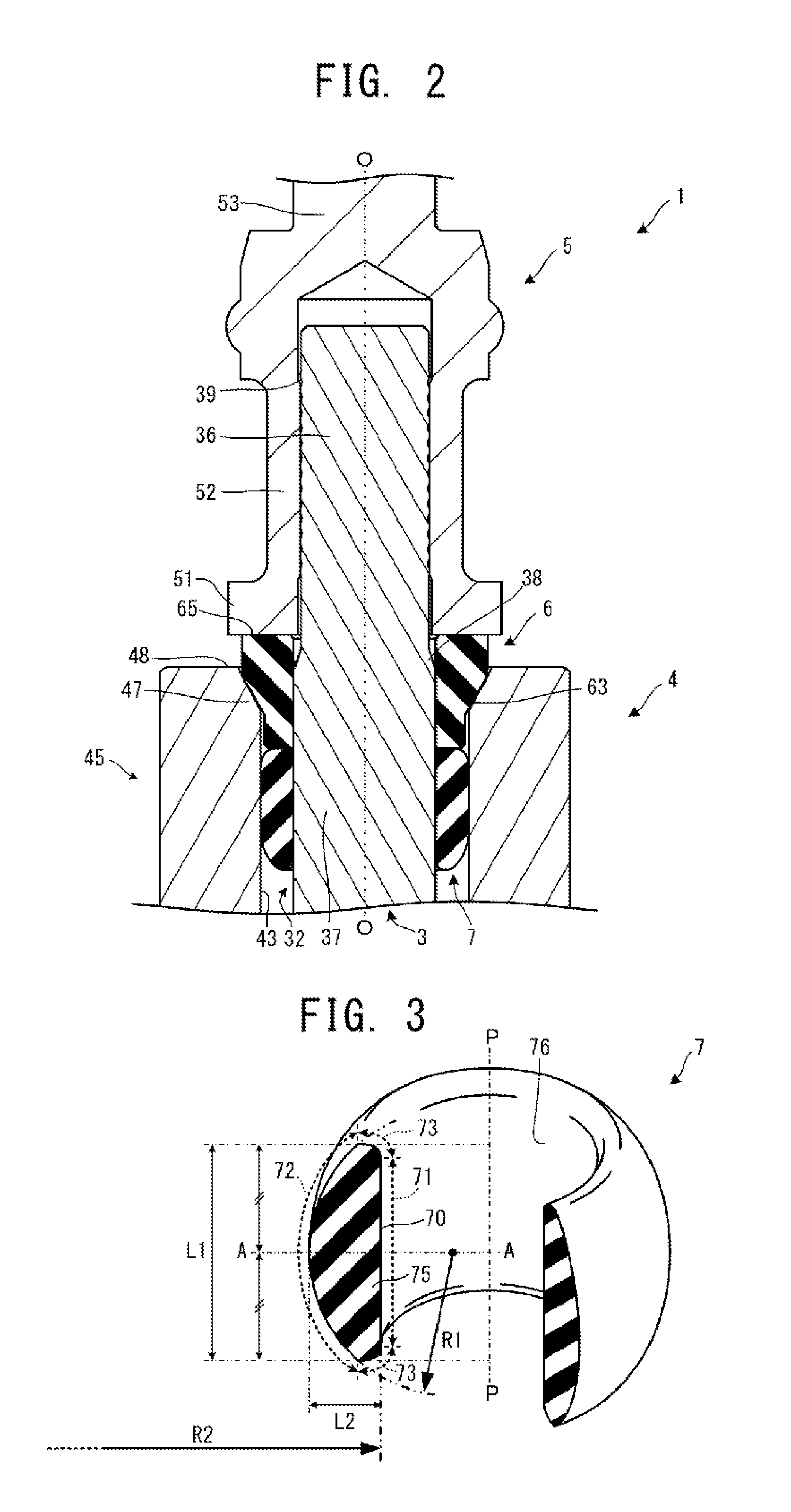

[0024]A glow plug according to an embodiment of the present invention will next be described with reference to the drawings. The entire structure of a glow plug 1 is described, by way of example, with reference to FIGS. 1 and 2. The drawings referred to herein are used for explaining technical features which the present invention can employ, and the configuration, etc., of the glow plug appearing in the drawings are given by way of illustration and not of limitation. In the following description, the axis of a metallic shell 4 is referred to as the axis O, and the axis O serves as reference in describing the positional relationship, orientations, and directions of those component members of the glow plug 1 which are attached to the metallic shell 4. With respect to the extending direction of the axis O (hereinafter, may be referred to as “the direction of the axis O”), a side on which a ceramic heater 2 is disposed (the lower side in FIG. 1) is referred to as the forward side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com