Method and apparatus for imparting false twist to yarn before ring spinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

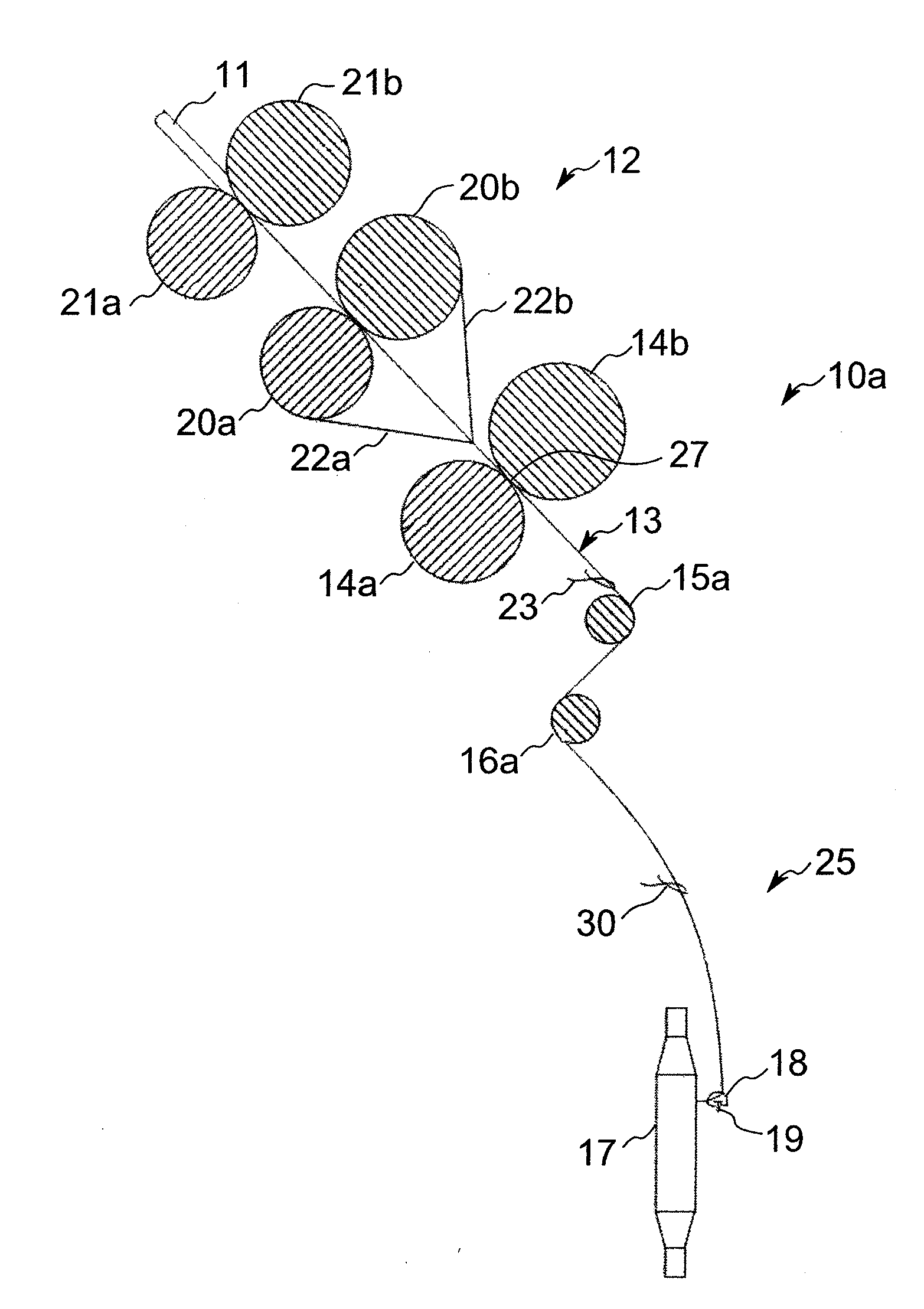

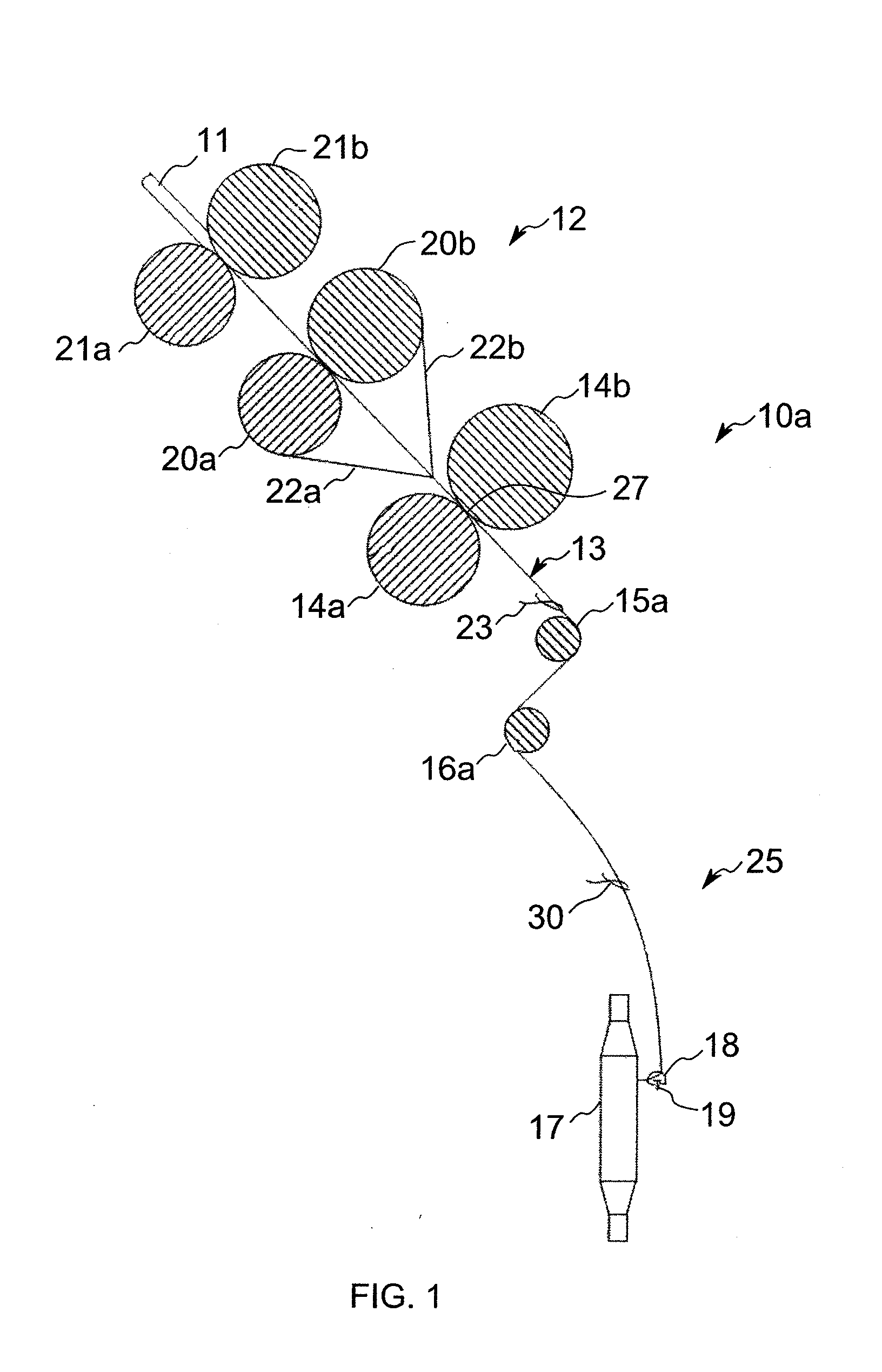

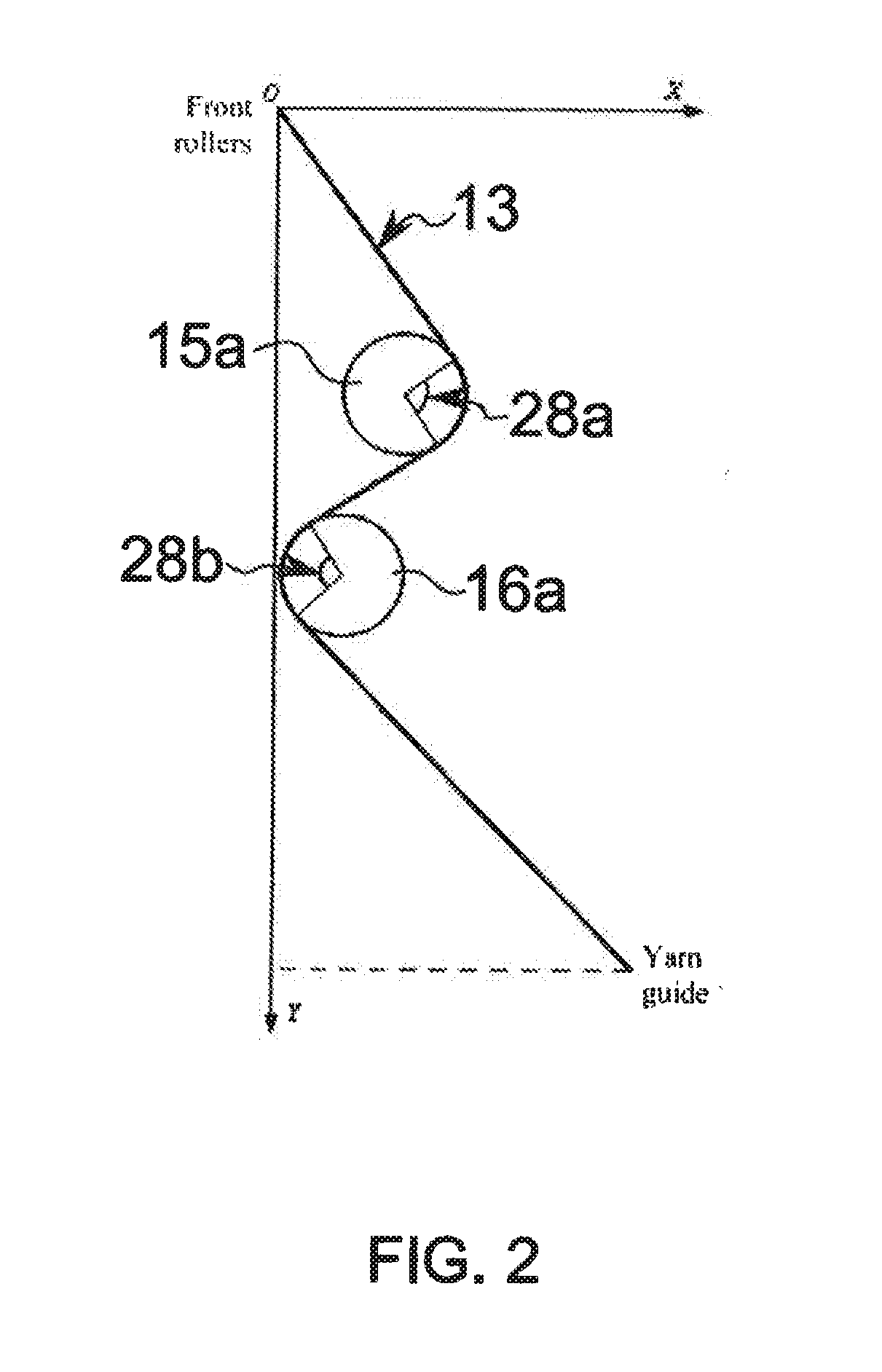

[0021]In machines 10a and 10b (shown in FIGS. 1 and 5 respectively) for spinning short staple fibres (those less than 2 inches or approximately 50 mm in length) the roving 11 (the precursor to the yarn 13) is fed into a drafting system 12 where it is drawn to its final count. The exemplary drafting system 12 is shown at an angle of 45° to the horizontal and may comprise a six-roller, double-apron drafting system. After the resulting thin ribbon of fibres leaves the delivery or front rollers 14, false twist is applied by the upper and lower linear runs 15a, 16a of two travelling endless belts 15, 16. The twist necessary for imparting strength is provided, in a direction opposite the false twist, by the take-up assembly 25 which also serves to draw the yarn 13 across the upper and lower linear runs 15a, 16a. The take-up assembly 25 is of conventional construction and includes the bobbin 17 rotating at high speed on a spindle. In the process each rotation of the traveller 18 on the spi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Speed | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Friction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com