Positive active material for rechargeable lithium battery and rechargeable lithium battery

a lithium battery and active material technology, applied in the direction of non-aqueous electrolyte accumulator electrodes, cell components, alkaline accumulators, etc., can solve the problems of unsatisfactory electrodes, and achieve excellent high-rate charge and discharge and cycle-life characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0070]85 wt % of LiCoO2 having an average particle diameter of 6.6 μm, 5 wt % of activated carbon having an average particle diameter of 6.8 μm (pitch-based, Kuraray Chemical Co.), 4 wt % of an acetylene black (Denka Chemicals Korea Co. Ltd.) conductive material, and 6 wt % of a polyvinylidene fluoride binder were mixed in an N-methylpyrrolidone solvent, preparing a positive active material slurry.

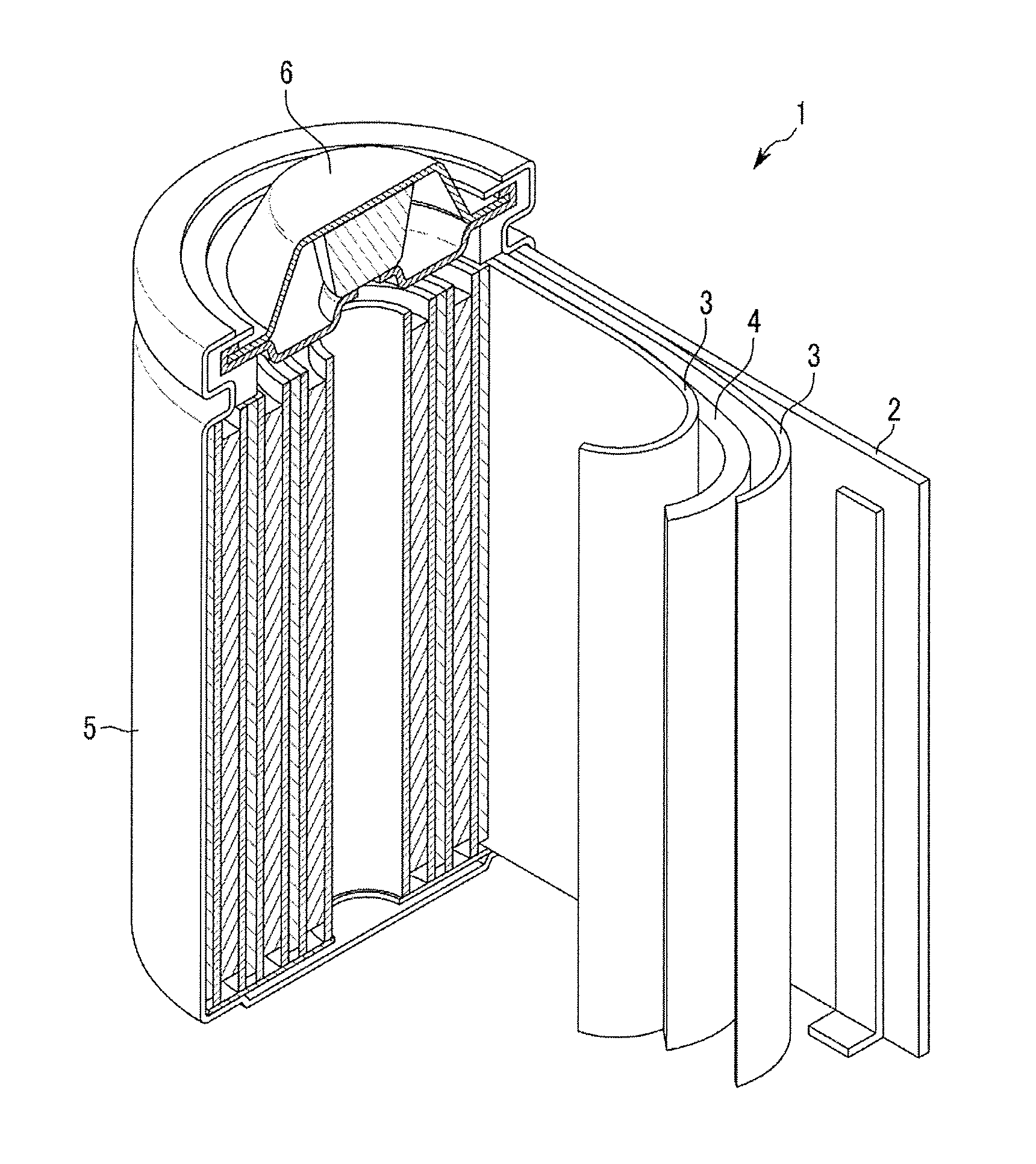

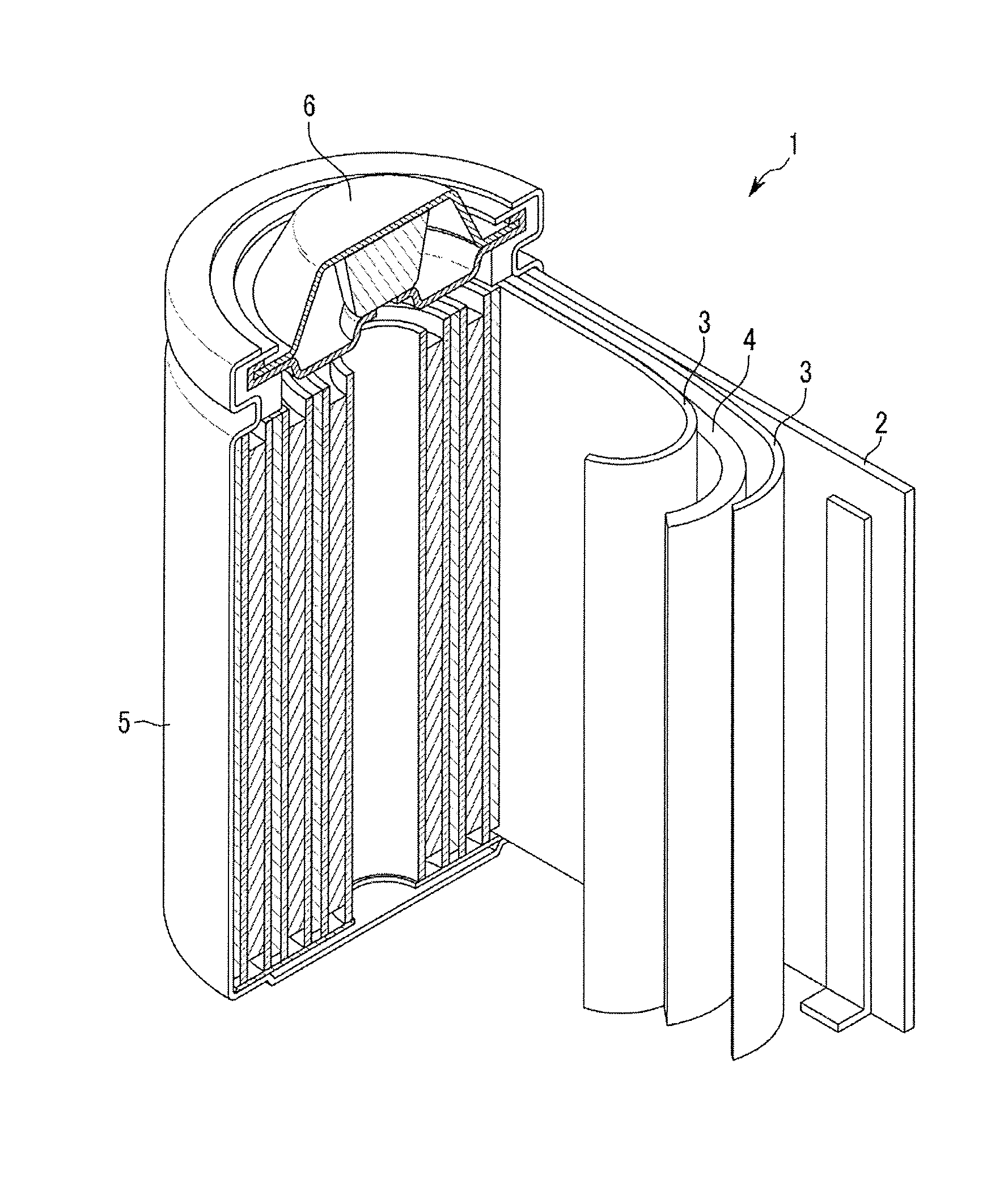

[0071]The positive active material slurry was coated on a 15 μm-thick Al foil, dried at 100° C., and compressed, fabricating a positive electrode having an active mass (positive active material layer) density of 2.6 g / cc.

[0072]Additionally, a negative active material slurry was prepared by mixing 85 wt % of a soft carbon (Hitachi Ltd.) negative active material having an average particle diameter of 10 μm, which was an amorphous carbon, 5 wt % of acetylene black (Denka Chemicals Korea Co. Ltd.), and 10 wt % of a polyvinylidene fluoride binder were mixed in an N-methylpyrrolidone solvent.

[00...

example 2

[0076]A rechargeable lithium battery cell was fabricated according to the same method as Example 1 except for mixing 85 wt % of LiCoO2 having an average particle diameter of 6.4 μm, 5 wt % of activated carbon (pitch-based, Kuraray Chemical Co.) having an average particle diameter of 6.65 μm, 4 wt % of an acetylene black (Denka Chemicals Korea Co. Ltd.) conductive material, and 6 wt % of a polyvinylidene fluoride binder in an N-methylpyrrolidone solvent to prepare a positive active material slurry.

example 3

[0077]A rechargeable lithium battery cell was fabricated according to the same method as Example 1 except for mixing 85 wt % of LiCoO2 having an average particle diameter of 6.6 μm, 5 wt % of activated carbon (pitch-based, Kuraray Chemical Co.) having an average particle diameter of 8.08 μm, 4 wt % of an acetylene black (Denka Chemicals Korea Co. Ltd.) conductive material, and 6 wt % of a polyvinylidene fluoride binder in an N-methylpyrrolidone solvent to prepare a positive active material slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com