Toilet flushing device and flush toilet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

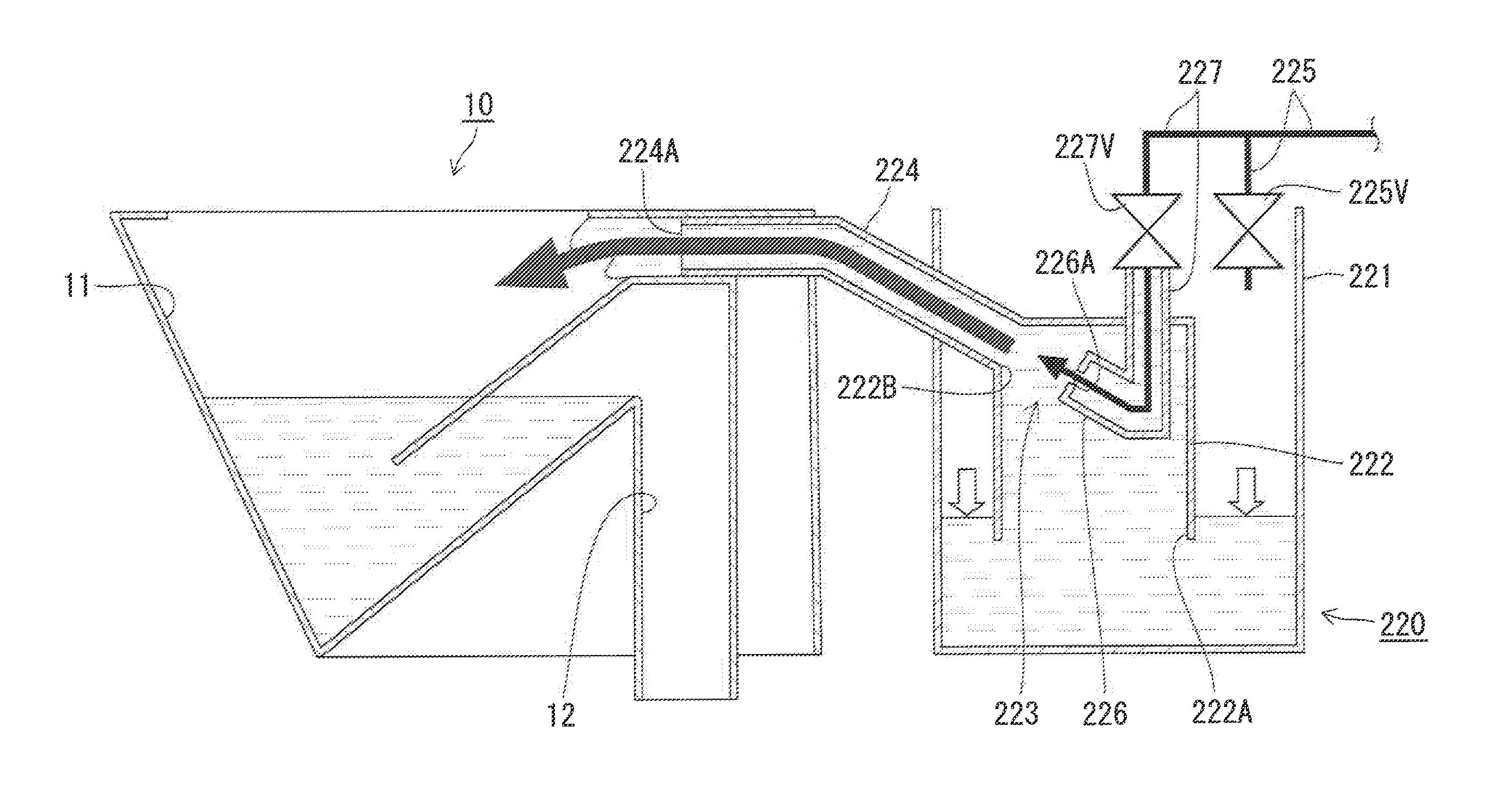

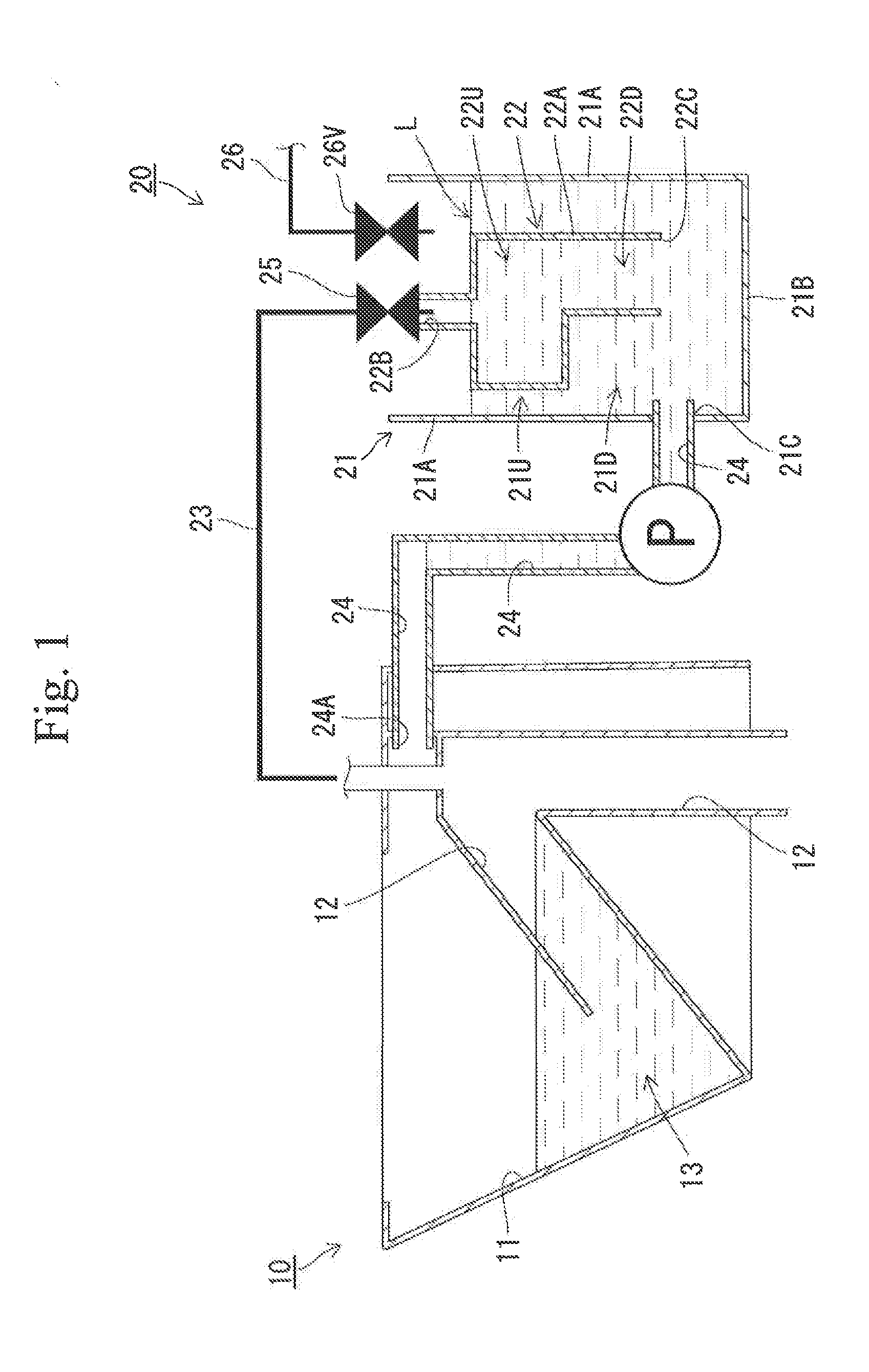

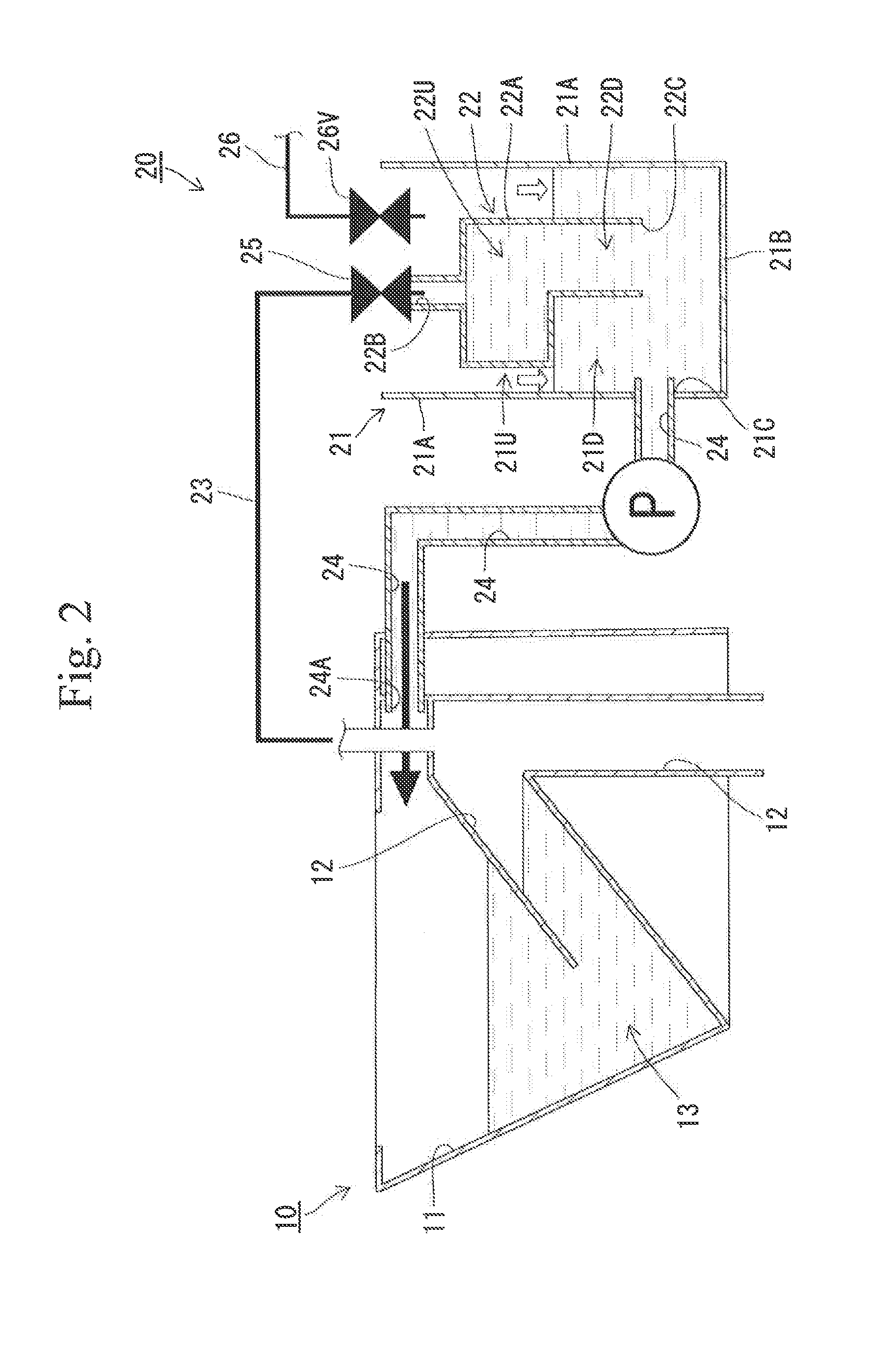

[0075]The flush toilet of embodiment 1 includes a toilet body 10 and a toilet flushing device 20 supplying flush water to the toilet body 10 as shown in FIG. 1. The toilet body 10 includes a toilet bowl 11 and a toilet drainage 12 communicating with a downstream side of the toilet bowl 11. A water sealing portion 13 retaining flush water is formed by a lower part of the toilet bowl 11 and an upstream of the toilet drainage 12.

[0076]The toilet flushing device 20 is located in the rear of the toilet body 10 and a large part of the toilet flushing device 20 is disposed lower than an upper surface of the toilet body 10. Consequently, the flush toilet achieves low silhouette. The toilet flushing device 20 includes a first tank 21, a second tank 22, an air passage 23, a water-supply passage 24 and an on-off valve 25 serving as a delay unit.

[0077]The first tank 21 has an upper end which is upwardly open and includes a vertically extending peripheral wall 21A and a bottom wall 21B closing a...

embodiment 2

[0098]A flush toilet according to embodiment 2 differs from embodiment 1 in that the toilet flushing device 30 includes a third tank 32 and flush water stored in the first tank 31 is supplied into the toilet body 10 by making use of a jet pump 33, as shown in FIG. 7. The other configuration of the flush toilet is the same as that of embodiment 1 and accordingly, an identical or similar structure is labeled by the same reference symbol as that in embodiment 1 and detailed description of such structure will be eliminated.

[0099]The toilet flushing device 30 is located in the rear of the toilet body 10 and a large part of the toilet flushing device 30 is disposed lower than an upper surface of the toilet body 10. Consequently, the flush toilet achieves low silhouette. The toilet flushing device 30 includes a first tank 21, a second tank 22, an air passage 23, a water-supply passage 24, an on-off valve 25 serving as a delay unit, a third tank 32 and a jet pump 33.

[0100]The first tank 31 ...

embodiment 3

[0135]The flush toilet according to the third invention includes the toilet body 10 and a toilet flushing device 300 as shown in FIG. 15. The toilet body 10 includes the toilet bowl 11 and the toilet drainage 12 communicating with the downstream side of the toilet bowl 11. The toilet bowl 11 has a rim water passage 14 formed along an opening edge of the upper side. The toilet drainage 12 has an upstream end communicating with a lower end of the toilet bowl 11. The toilet drainage 12 includes a region from a top thereof (a highest part) to the lower end of the toilet bowl 11. The region serves as water sealing, portion 13. The toilet drainage 12 has an air flow hole 15 which is located downstream with respect to the water sealing portion 13 and open above the water sealing portion 13. The toilet drainage 12 further has a narrow portion 16 which is provided in a region extending downward from the air flow hole 15 and has a reduced diameter.

[0136]The toilet flushing device 300 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com