Blasting Method Using a Control Device for Inducing a Blast Pressure, and Control Device for Inducing the Blast Pressure to Apply the Method

a control device and blast pressure technology, applied in the field of innovative blasting techniques, can solve the problems of small control effect, low control effect, and large cost, and achieve the effects of increasing blast efficiency, reducing blast cost, and reducing economic ripple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]Preferred examples for embodying means for achieving the object of the present invention will be described.

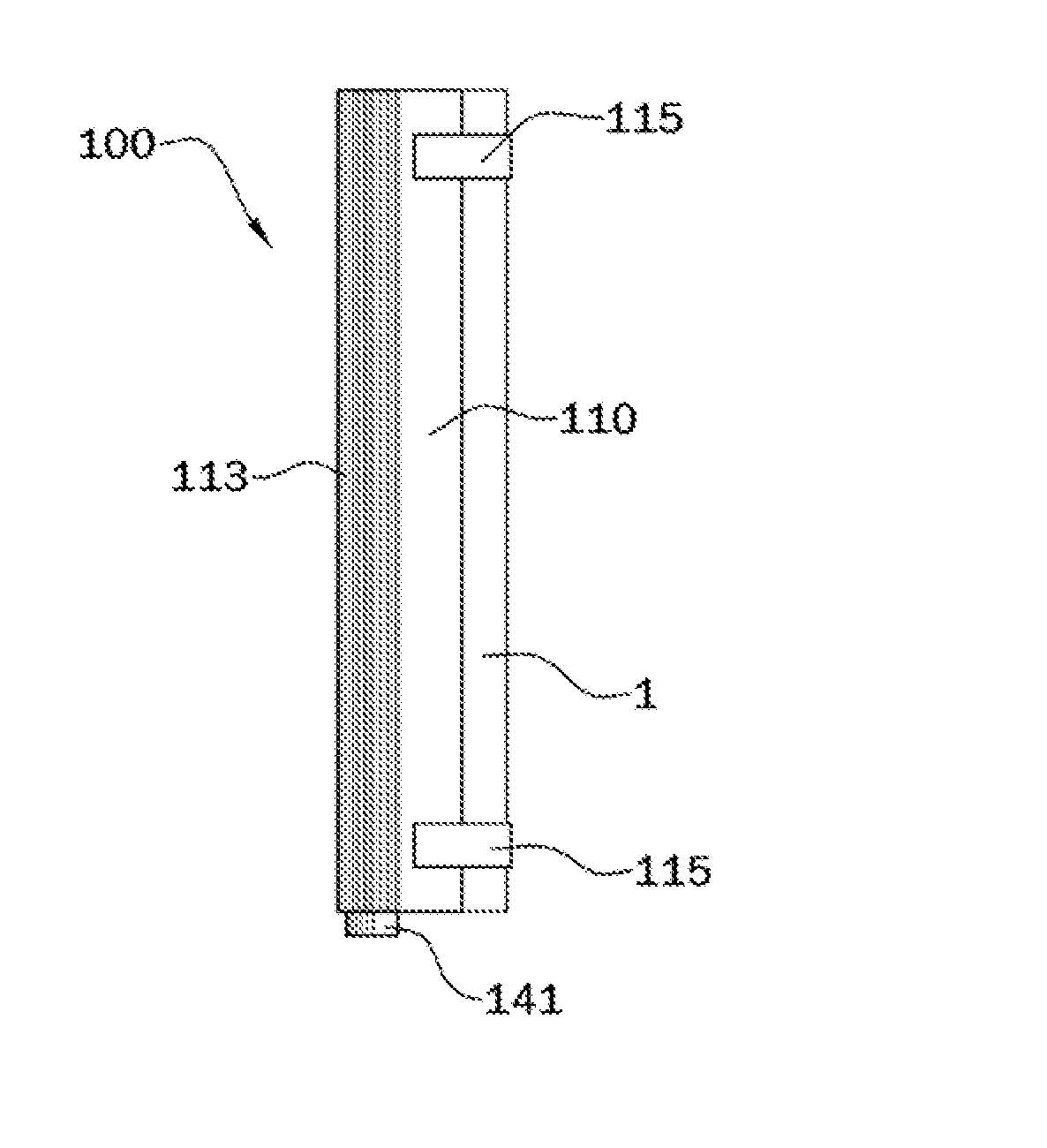

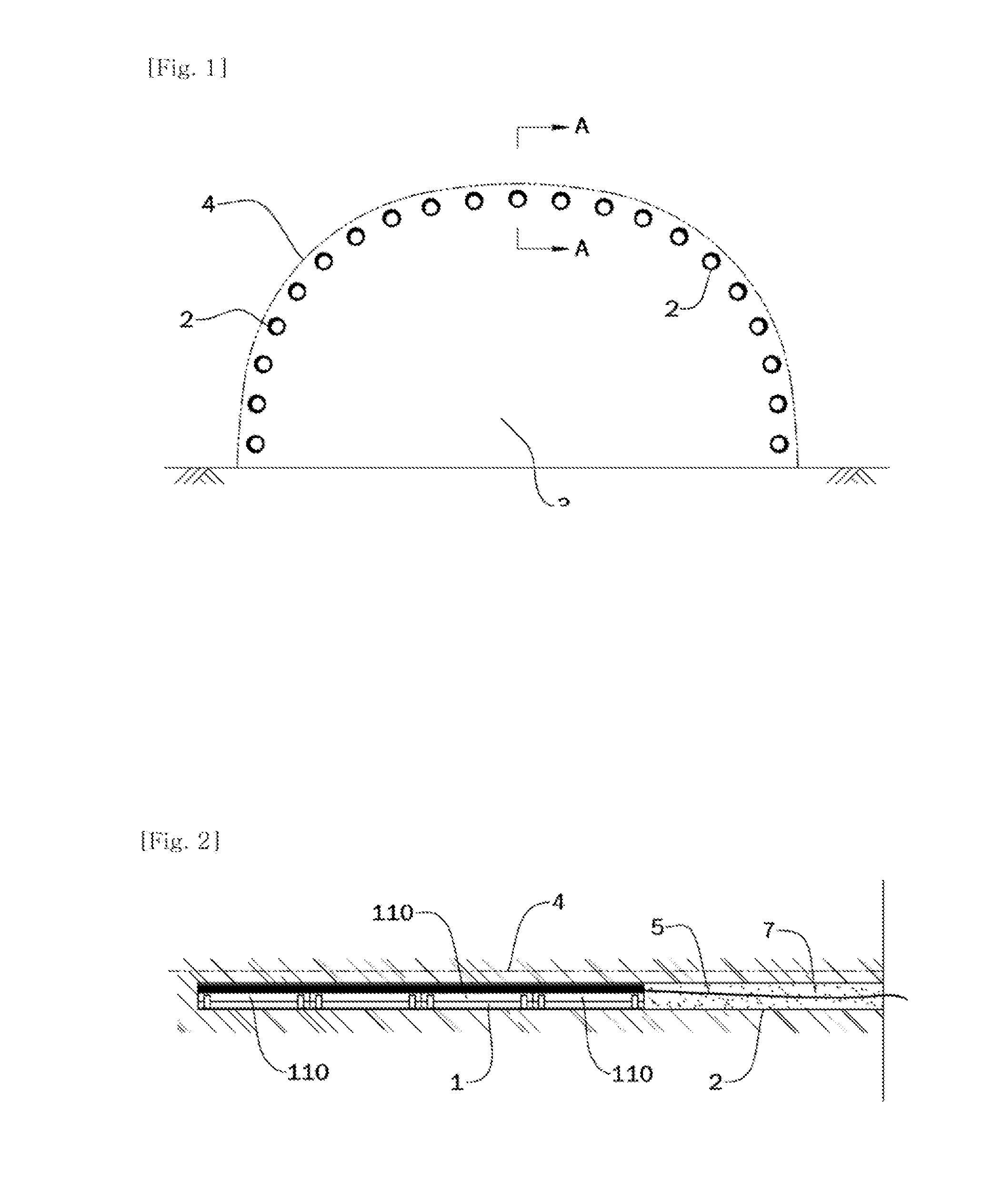

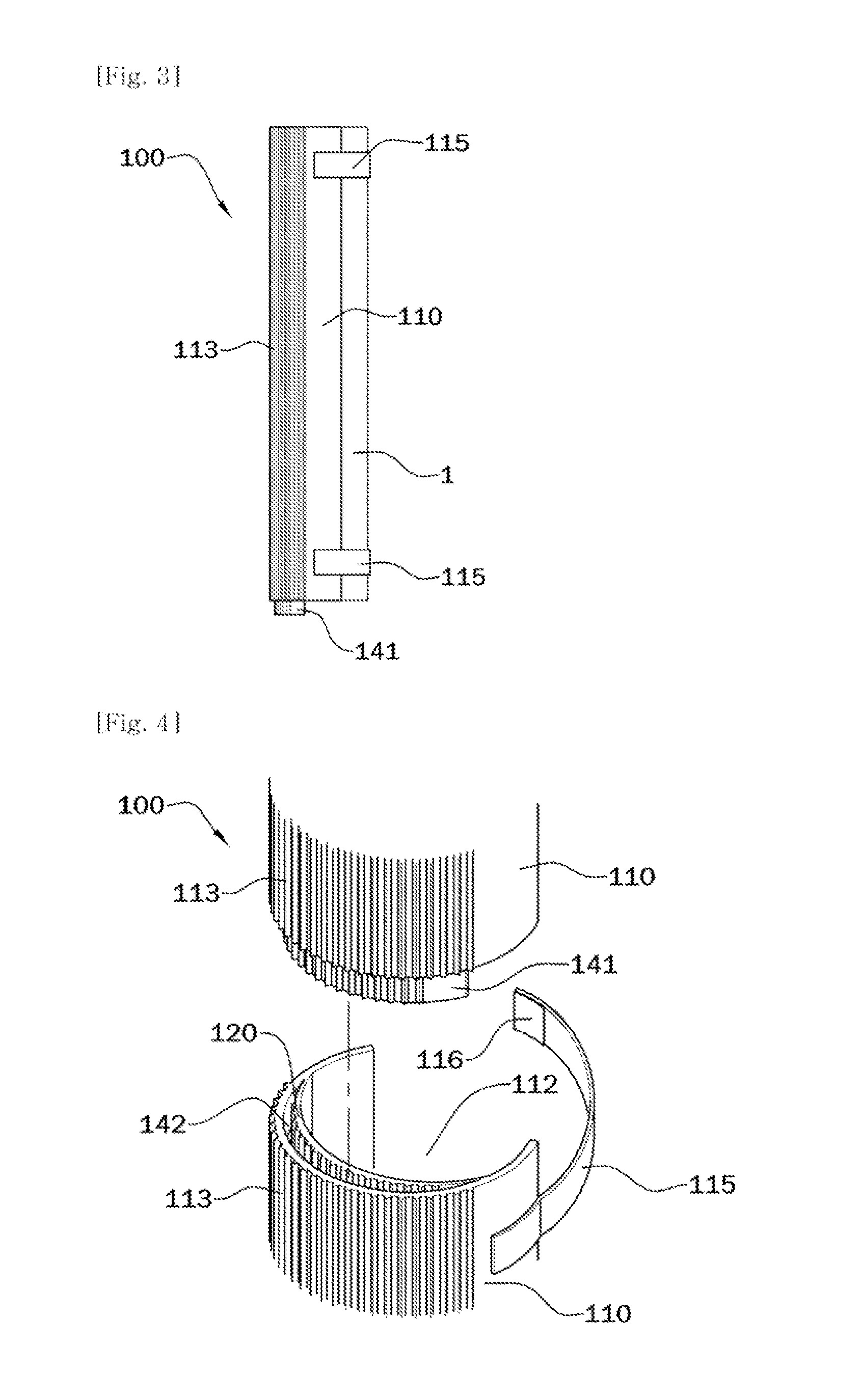

[0026]Brief description is as follows about a blasting method using blast pressure-guiding control device according to preferred examples of the present invention. The blasting method comprises explosive-loading step (S10) wherein the explosive (1) is loaded in each of a plurality of blast pressure-blocking covers (110) formed with a blast pressure-guiding passage (11) therein and thereafter the explosive (1) is fixed by wrapping it with connecting bands (115); cover-assembling step (S20) wherein the plurality of blast pressure-blocking covers (110) are longitudinally connected and assembled; cover-installing step (S30) wherein the plurality of blast pressure-blocking covers (110) thus connected and assembled are inserted and installed in blast holes (2) so as to face a predetermined blast line (4); tamping-charging step (S40) wherein the tamping (7) is charged in the bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com