Mouthpiece

a mouthpiece and mouth technology, applied in the field of mouthpieces, can solve the problems of short time for ending the vaporization of nicotine from tobacco leaves, harming the flavor,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

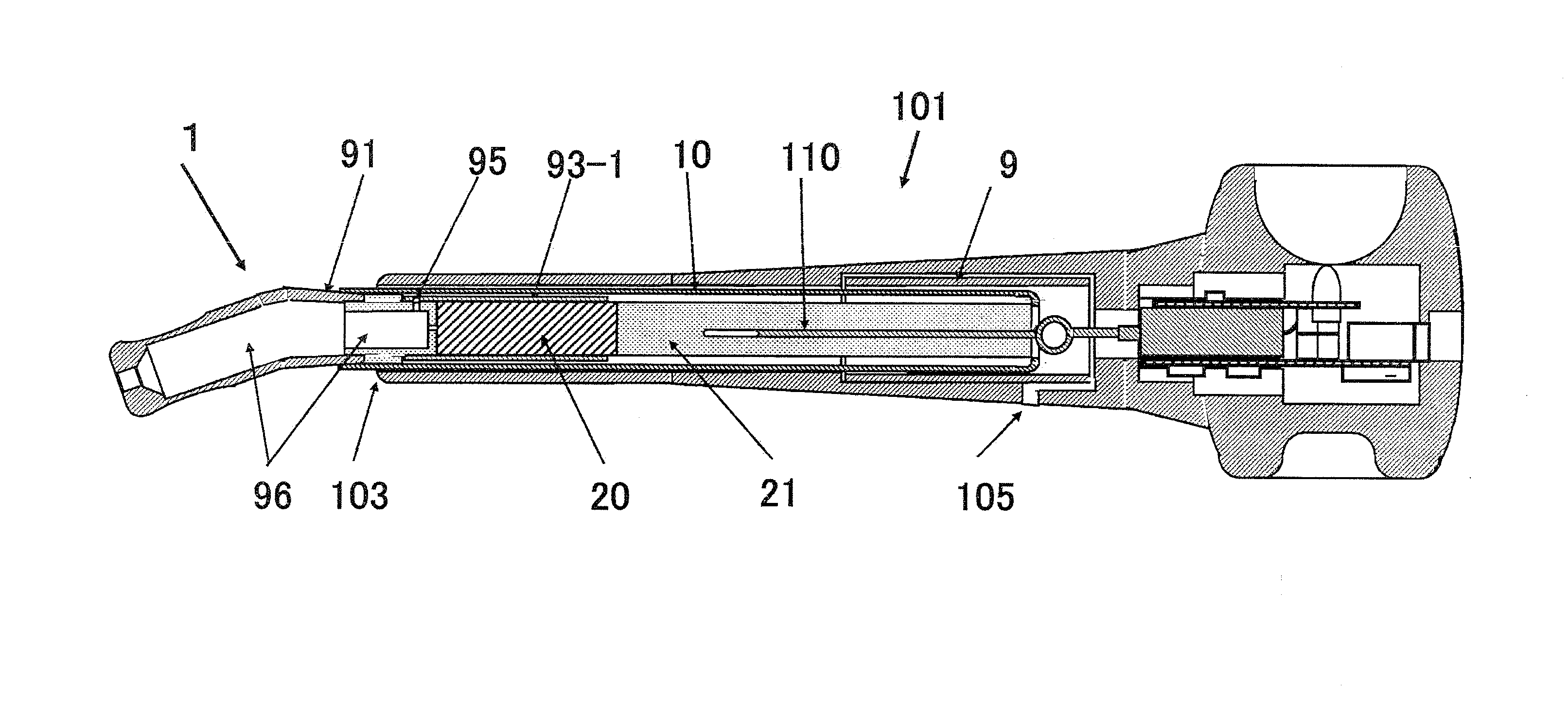

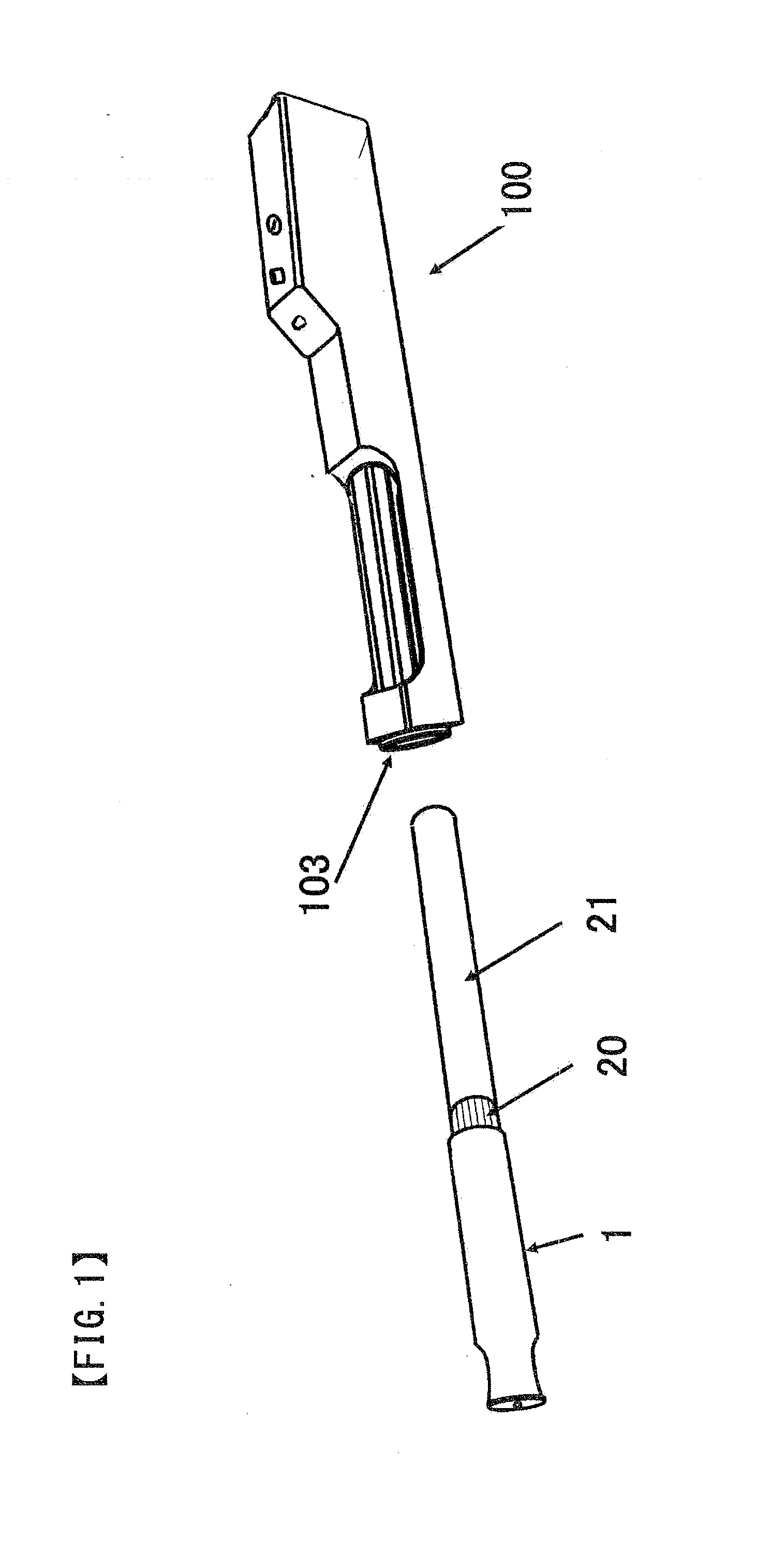

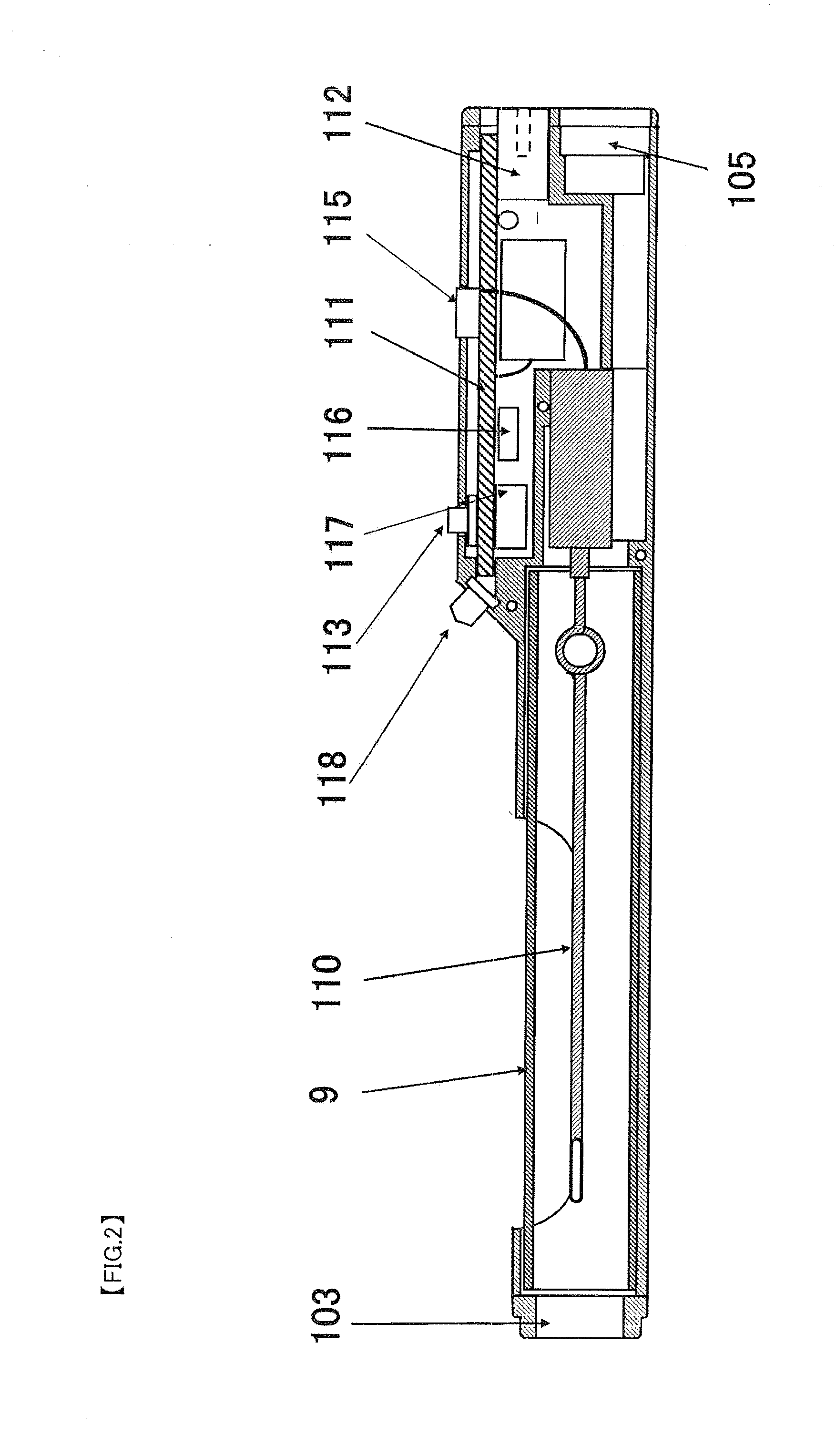

[0052]FIG. 3 shows a cross-sectional view of a mouthpiece of EXAMPLE 1 of the present application. The mouthpiece 1 comprises an inhalation inlet 2, an air flow control element 3 and a filter housing part 4. As shown in FIG. 4, the air flow control element 3 comprises a combination of two components 31 and 34. The outer diameter of the component 31 is designed to be substantially the same as the inner diameter of the filter housing part 4. The outer diameter of the component 34 is designed to be substantially equal to or smaller than the outer diameter of the component 31, and equal to or larger than the diameter of an axial hole 32. The mouthpiece 1 has an outer diameter designed to tightly fit an insertion opening 103 of the non-combustion smoking tool shown in FIGS. 1 and 2 so as to prevent air leakage.

[0053]FIG. 5 shows an appearance view of another example of an air control component 3. This air control component 3 has a shape similar to a normal gear, and comprises six gear te...

example 2

[0062]FIG. 7 shows an appearance view of a mouthpiece of EXAMPLE 2 of the present application. FIG. 8 is an A-A′ cross-sectional view of FIG. 7. This mouthpiece comprises a mouthpiece outer case, an air flow control element 3-1 and a filter housing part 4.

[0063]As shown in FIG. 7 and FIG. 8, the mouthpiece 1 has two slits 6. The slits 6 serve to guide produced nicotine to the inhalation inlet 2, and facilitate insertion into the non-combustion smoking tool or facilitate insertion of a cigarette guide tube 10 by allowing the outer diameter of the mouthpiece 1 to be virtually reduced when the mouthpiece 1 is pressed from outside upon insertion into the non-combustion smoking tool or upon insertion of the cigarette guide tube 10 into the mouthpiece 1 as described later. Although FIG. 7 describes the case of two, the same effect can be obtained with three or more.

[0064]Further, the slits have length L1 which is designed to be longer than insertion length L2 of the filter cigarette in th...

example 3

[0072]FIG. 11 is an appearance view of a novel mouthpiece 1 of EXAMPLE 3 of the present application. FIG. 12 is a right side view of FIG. 11. This mouthpiece is an embodiment of the subject matter of the present invention based on the structure of the mouthpiece instead of the air flow control element. The mouthpiece 1 comprises four parts, in which 93 is a filter housing part, and has a portion to fit a part 92 as shown in a cross-sectional view of FIG. 13. This portion is rotated by a smoker for use so that a groove 94 is rotated to match one of holes 95-1, 2, 3. A hole 97 is formed in a central wall of the filter housing part 93. As shown in the cross-sectional view of FIG. 13, the part 92 is designed to fit a part 91 as well, and has the holes 95-1, 2, 3. A right side of the part 92 is a cover which has two holes 99 of different sizes. When the part 93 is rotated to allow the groove 94 to match the hole 95-1, a hole 99 with a diameter substantially equal to the hole 97 is positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com