Commutator

a commutator and commutator technology, applied in the field of commutators, can solve the problems of a large number of steps in the manufacture of commutators, and achieve the effect of high engagement for

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0035]A first embodiment according to the present invention will be described below based on FIGS. 1 to 7.

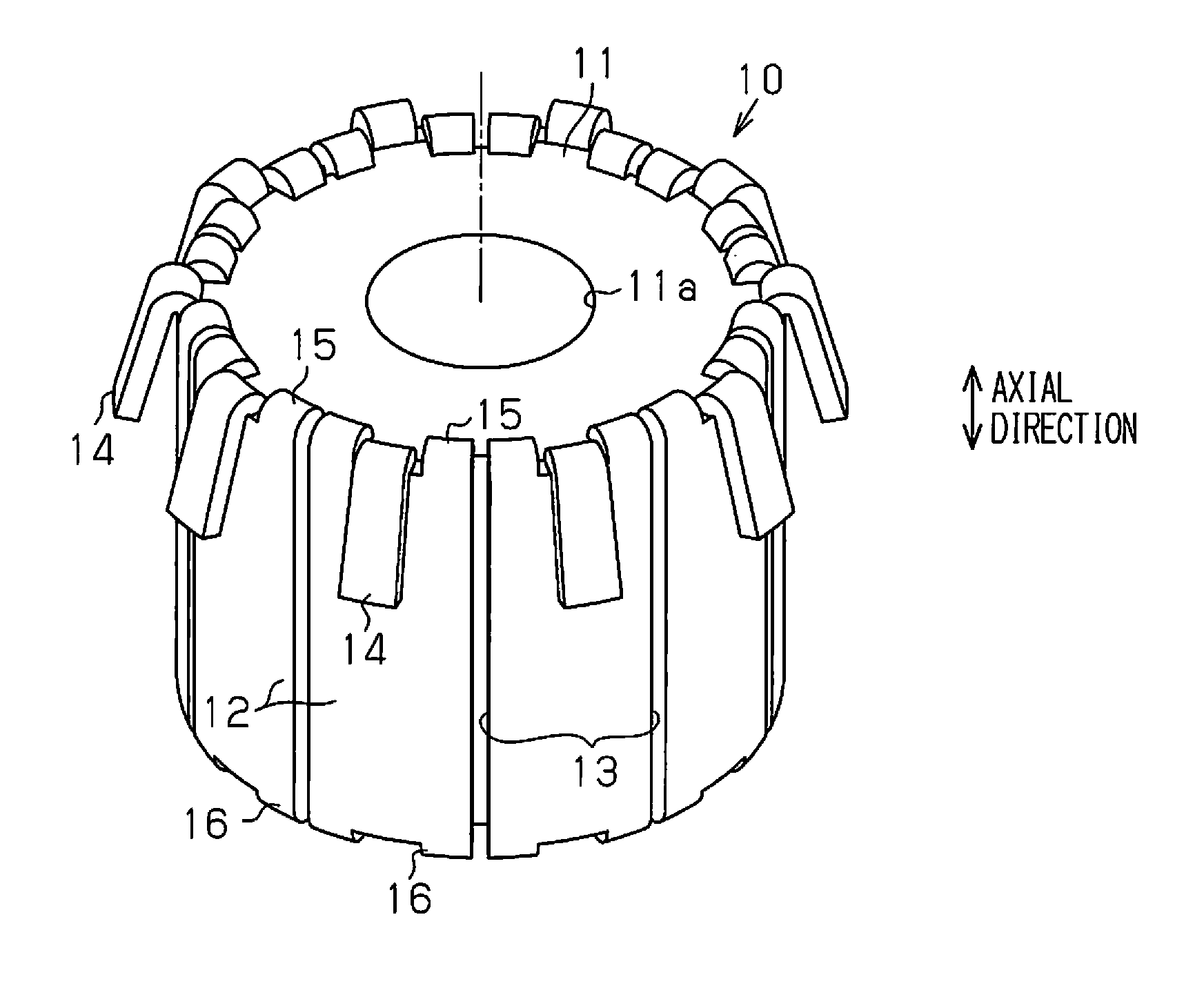

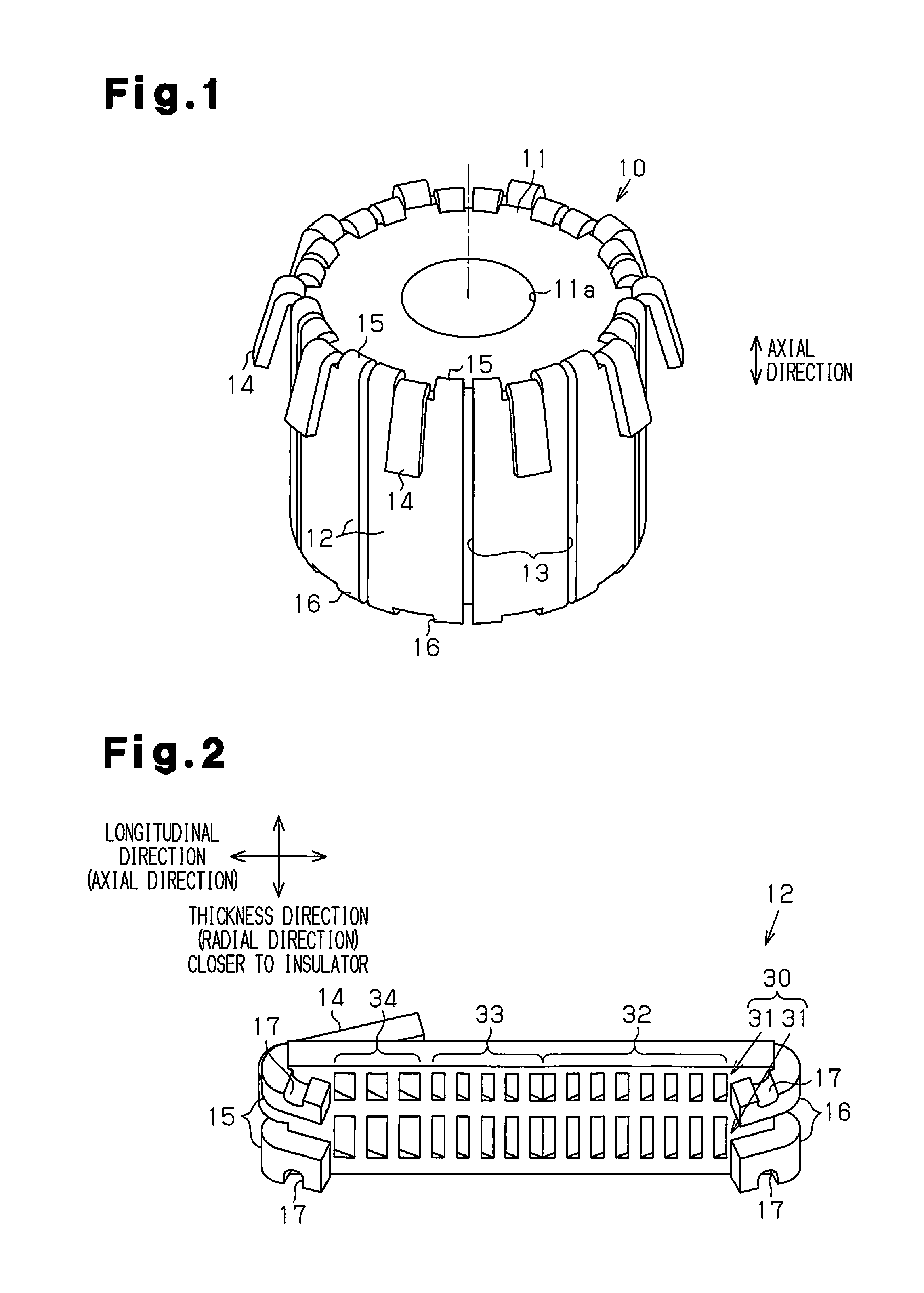

[0036]As shown in FIG. 1, a commutator 10 includes a cylindrical insulator 11 made of a thermosetting plastic, and ten segments 12 (commutator pieces) fixed to the outer circumferential surface of the insulator 11. A press-fitting hole 11a extending through the insulator 11 in the axial direction is formed at a radial central portion of the insulator 11. A rotary shaft of an armature (not shown) is press-fitted in the press-fitting hole 11a. Accordingly, the commutator 10 rotates integrally with the rotary shaft of the armature.

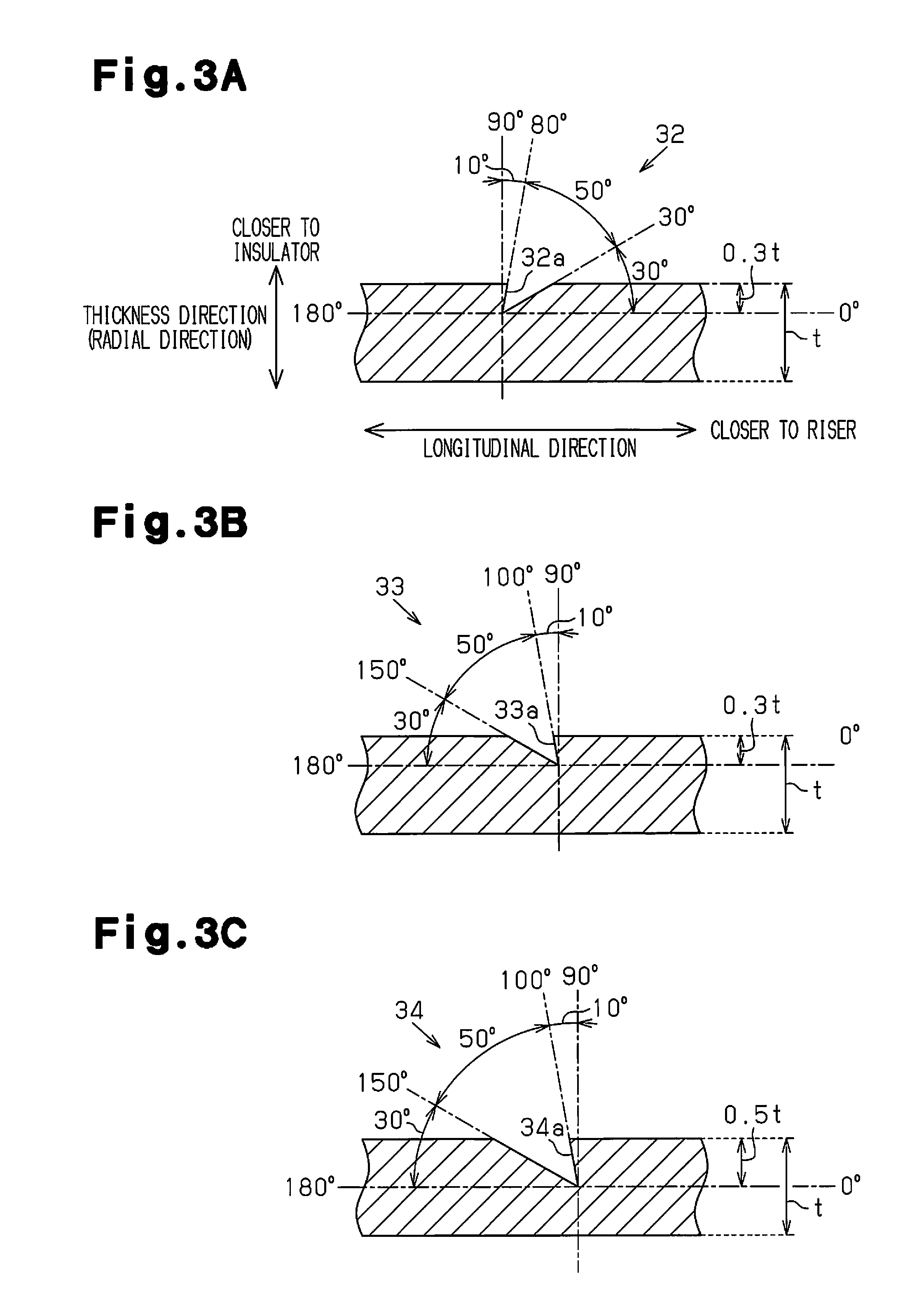

[0037]Each segment 12 is formed from a conductive plate material (for example, a metal plate such as a copper plate). The ten segments 12 are strips extending in the axial direction of the insulator 11 while being uniformly spaced angularly in the circumferential direction of the insulator 11. A partition groove 13 extending in the axial direction of the ...

second embodiment

[0061]A second embodiment of the commutator will now be described. The second embodiment mainly differs from the first embodiment in a first inner claw. Like or the same reference numerals are given to those components that are like or the same as the corresponding components of the first embodiment, and detailed explanations are omitted.

[0062]As shown in FIG. 10, a commutator 101 includes a cylindrical insulator 11, and eighteen segments 120 fixed to the outer circumferential surface of the insulator 11. The eighteen segments 120 are uniformly spaced angularly in the circumferential direction. The segments 120 each occupy an angle θ1 in the circumferential direction. Except for risers 14, second inner claws 16, and first inner claws 121, which will be described below, the eighteen segments 120 together have an inside diameter φ1 and an outer diameter φ2. Specifically, parts of the eighteen segments 120 excluding their risers 14, the second inner claws 16, and the first inner claws ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com