Sling Fittings and Sling System for a Firearm

a technology for sling fittings and firearms, applied in the field of sling fittings and sling systems for firearms, can solve the problems of requiring constant hands-on control of weapons, affecting weapon use in dynamic combat environments, and affecting the use of weapons, so as to achieve greater articulation of connection structures, greater freedom of movement, and greater range of movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056]With reference now to the drawings, the preferred embodiment of the sling fitting is herein described. It should be noted that the articles “a”, “an”, and “the”, as used in this specification, include plural referents unless the content clearly dictates otherwise.

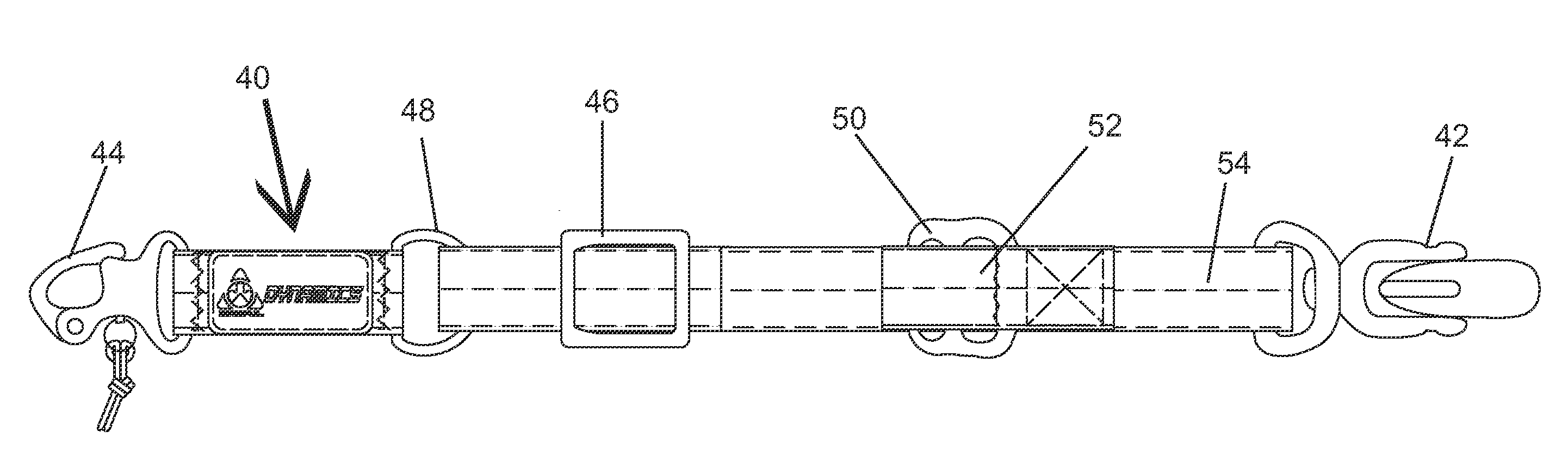

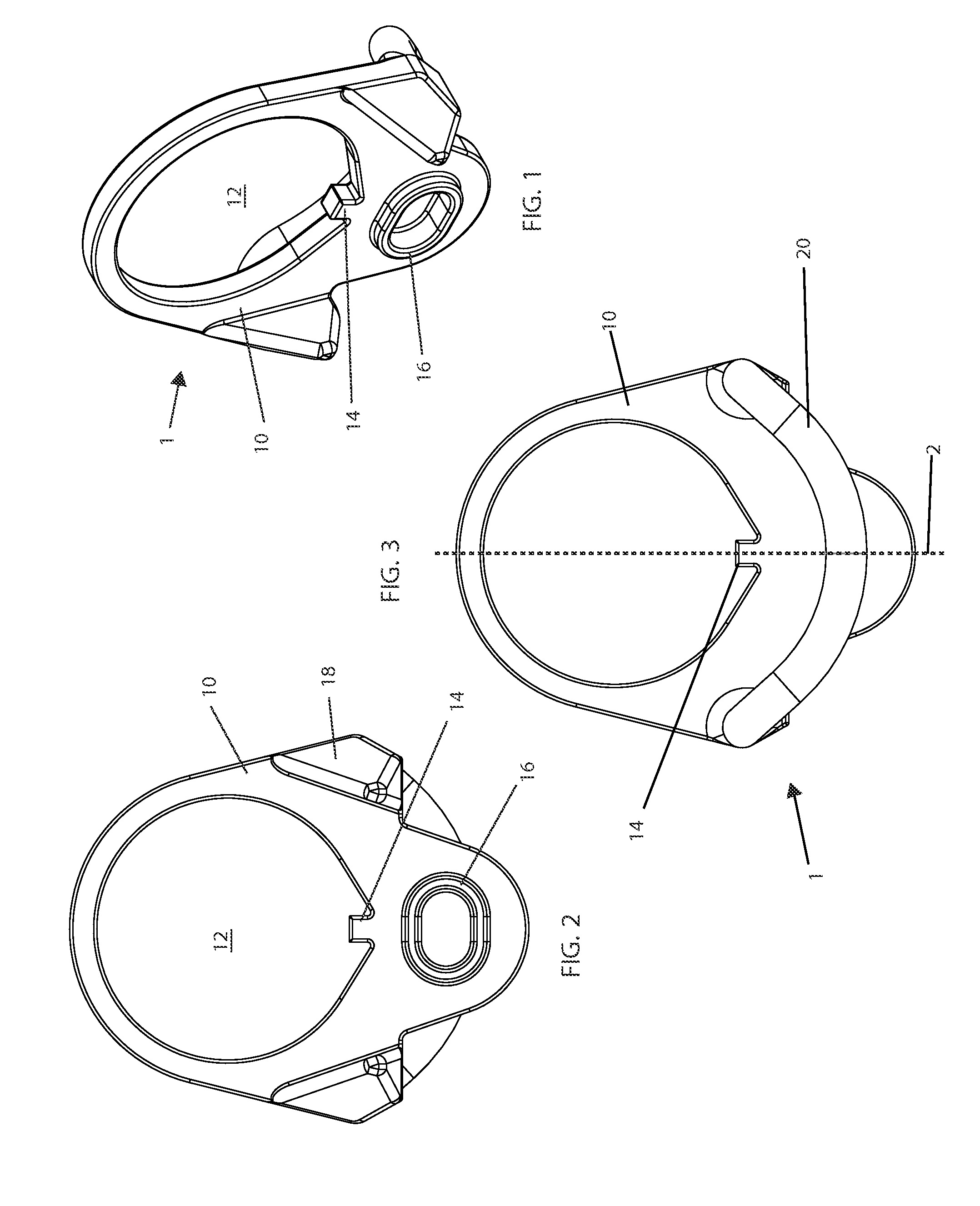

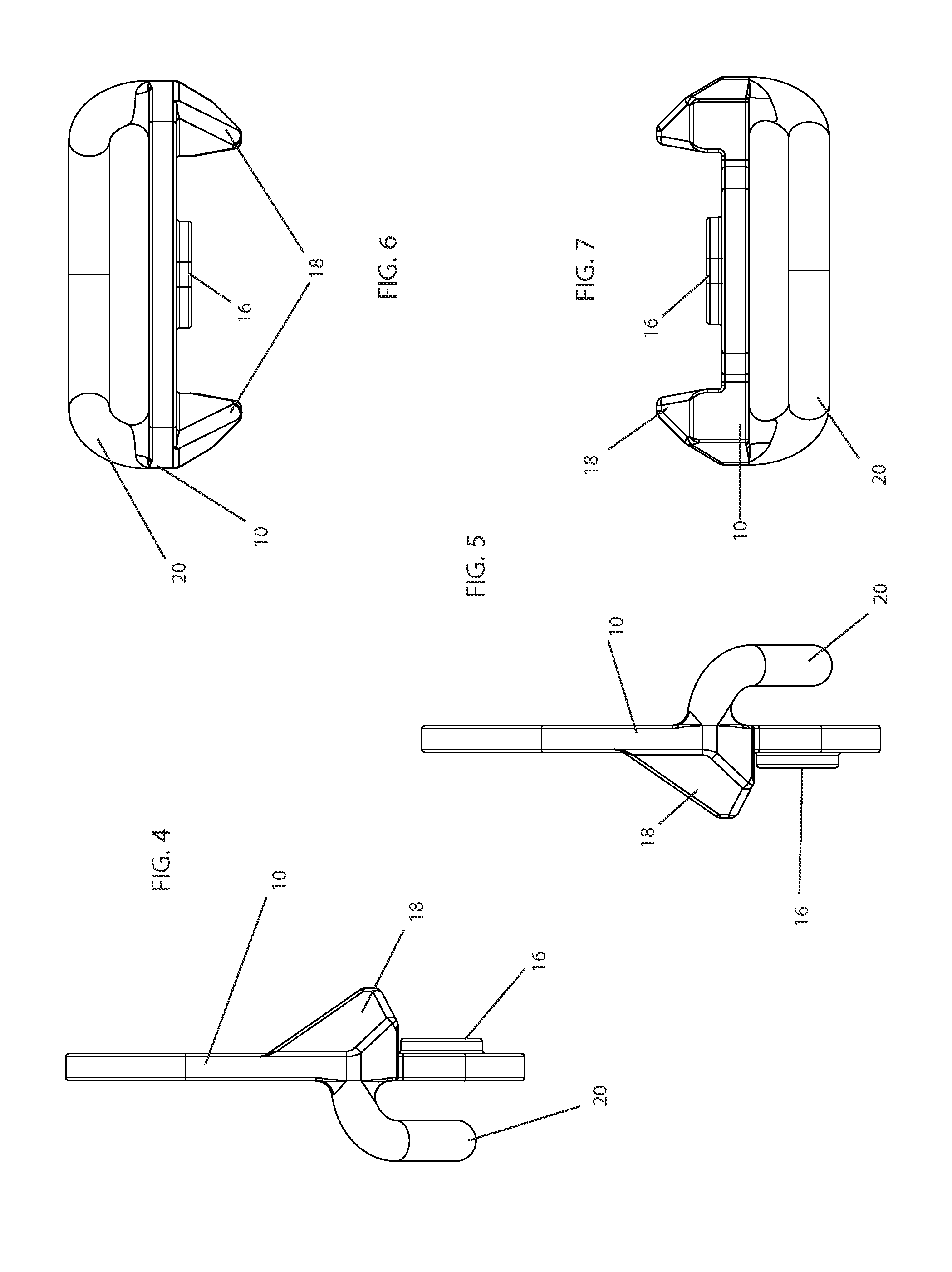

[0057]With reference to FIGS. 1-14 generally, the rear fitting 1 comprises a main fitting body 10 with an ovular shape. The wider portion of the main body circumscribes and defines an aperture 12, through which a receiver tube will slide when the fitting 1 is installed. A registration tab 14 is present in the lower part of aperture 12, extending from the circumference of the aperture, to register the sling fitting 1 on the receiver tube, as the receiver tubes for adjustable and collapsible stocks have a distal grove throughout the length of the tube. For fixed stock applications, where no such groove is present, registration tab 14 may be omitted. The lower portion of the fitting body 10 is narrower and presents a reg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com