Grounding device for welders

a grounding device and welder technology, applied in the direction of coupling device connection, coupling part engagement/disengagement, connection contact member material, etc., can solve the problems of inconvenient welding, potential damage to ground wire, and inability to easily remove and move without twisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]The present invention is a magnetic grounding clamp for portable vet secure connection of a welder grounding lead to earth ground using virtually any grounding body including irregular-shaped objects such as pipes and metal cylinders.

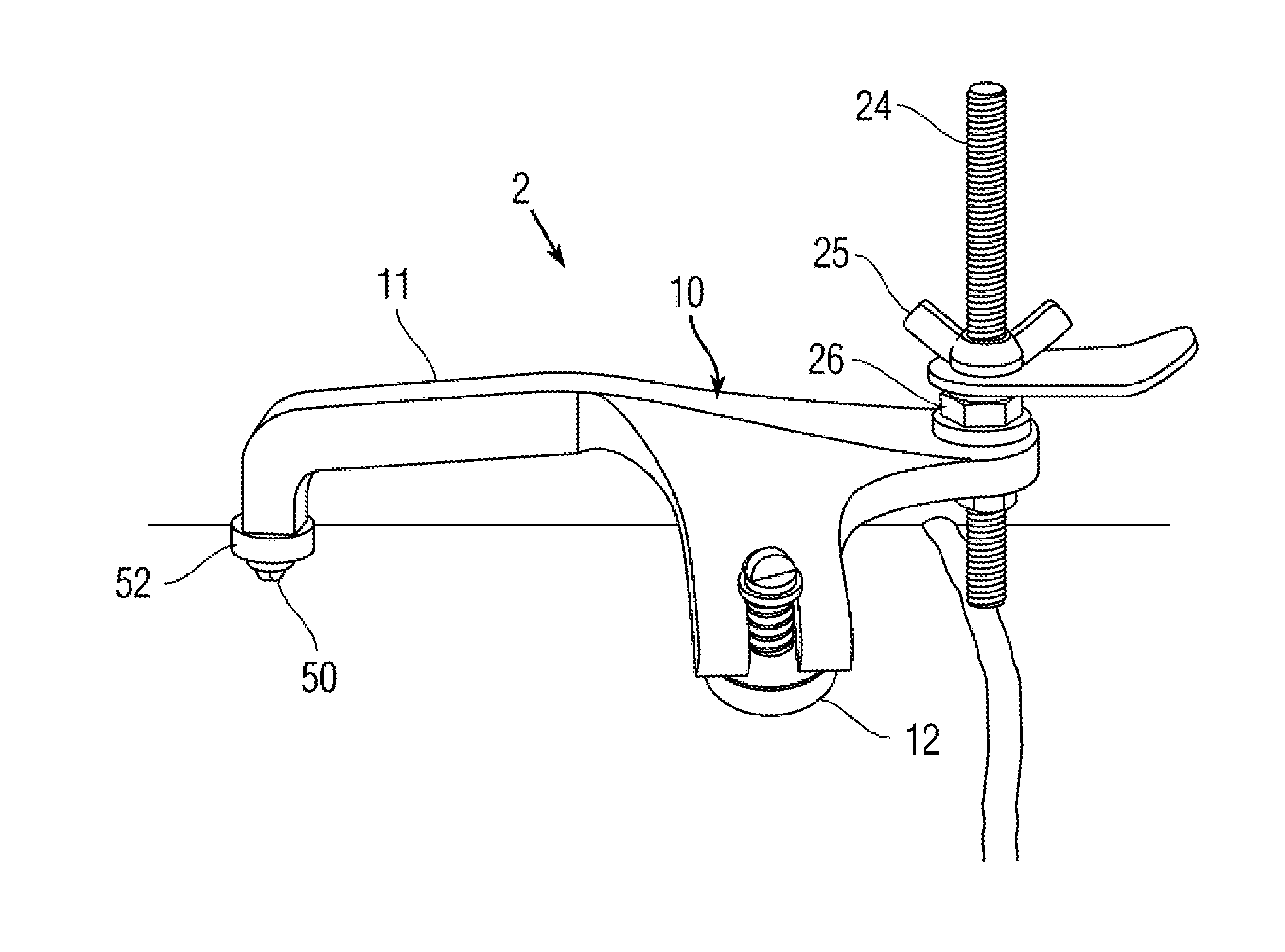

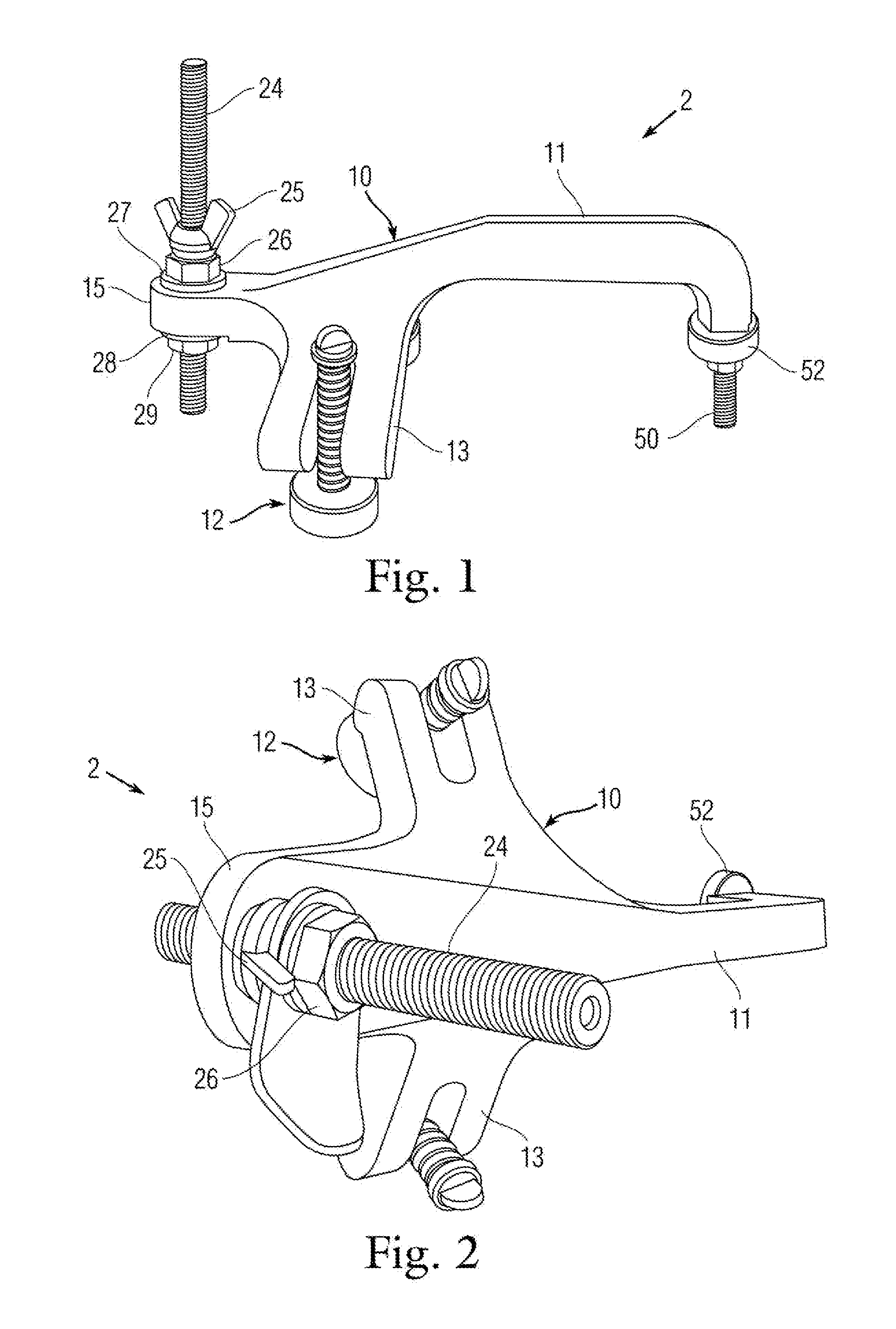

[0020]With collective reference to FIGS. 1-2, the magnetic grounding clamp 2 generally comprises a stabilizing body 10 having a long forwardly-protruding neck 11, two relatively short opposing legs 13, and a short tail section 15. A disk-magnetic foot assembly 12 is attached distally at the end of each leg 13. The body 10 is preferably formed as a unitary cast-aluminum member shaped as a quadruped, though other suitable material may exist. The legs 13 protrude perpendicularly on opposing sides of body 10 and are preferably angled (as shown) or arched downward therefrom slightly downward to provide elevation and to supinate the magnetic feet assemblies 12 slightly.

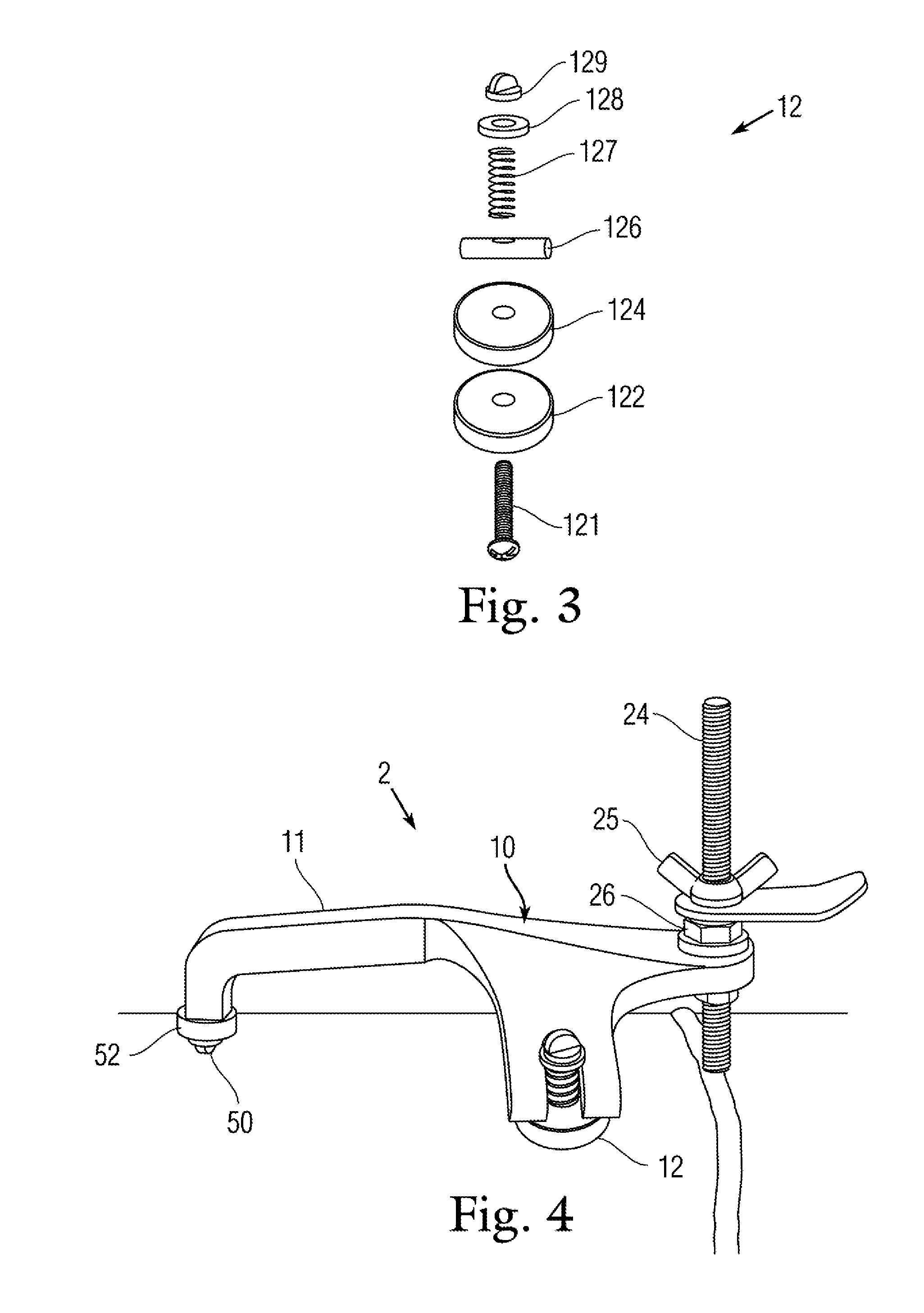

[0021]FIG. 3 is an exploded view of a magnetic foot assembly 12. Each magnetic foot 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com