Heat exchanger

a technology of heat exchanger and heat exchanger body, which is applied in the direction of indirect heat exchanger, stationary tubular conduit assembly, light and heating apparatus, etc., can solve the problems of reducing the pressure of the tank, and achieve the effect of reducing the running cost of the present invention, reducing the size of cooling facilities, and reducing the cost of facilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

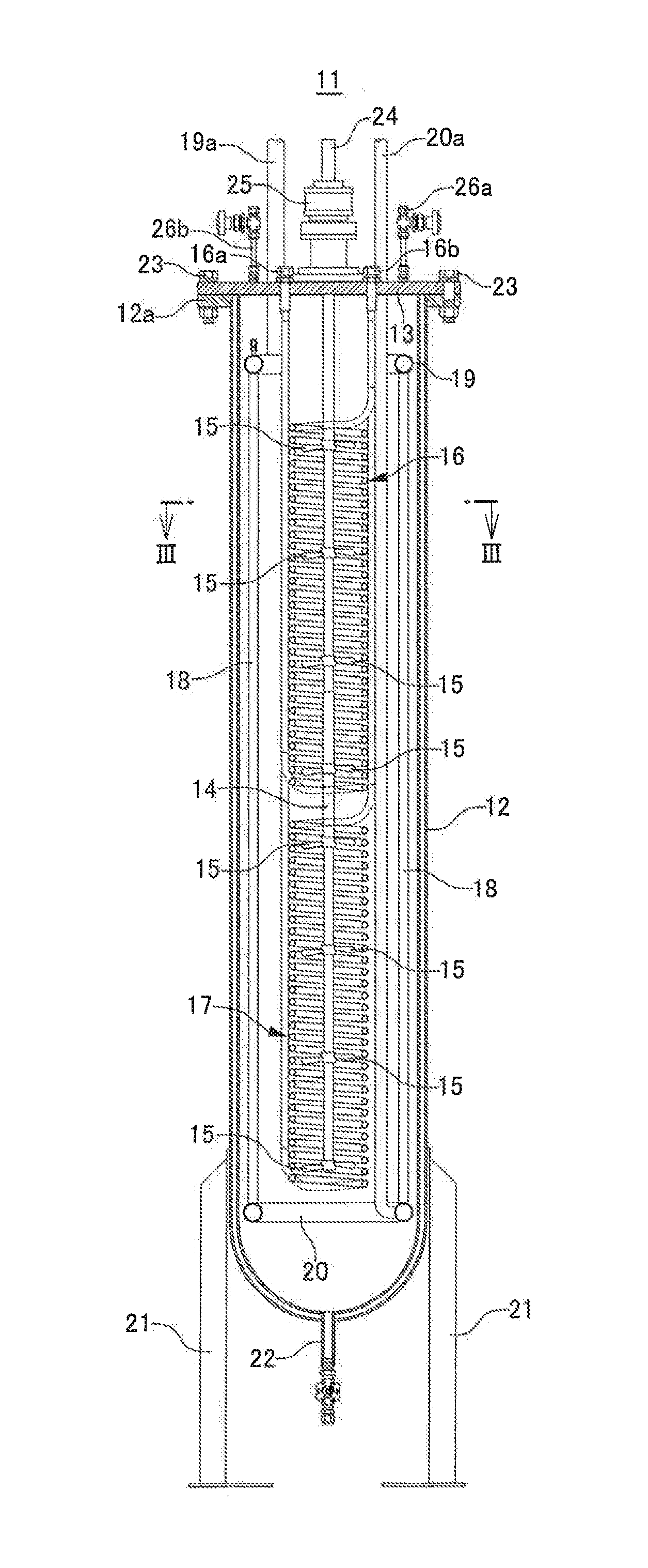

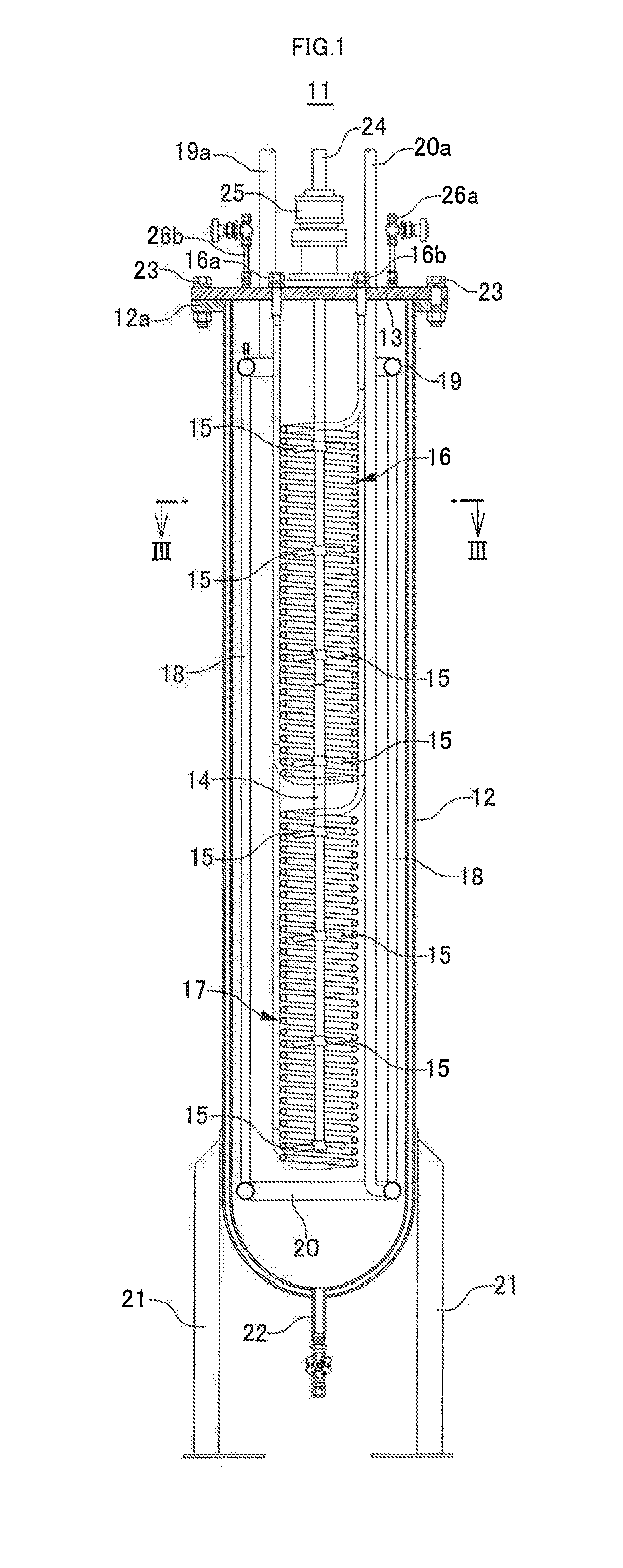

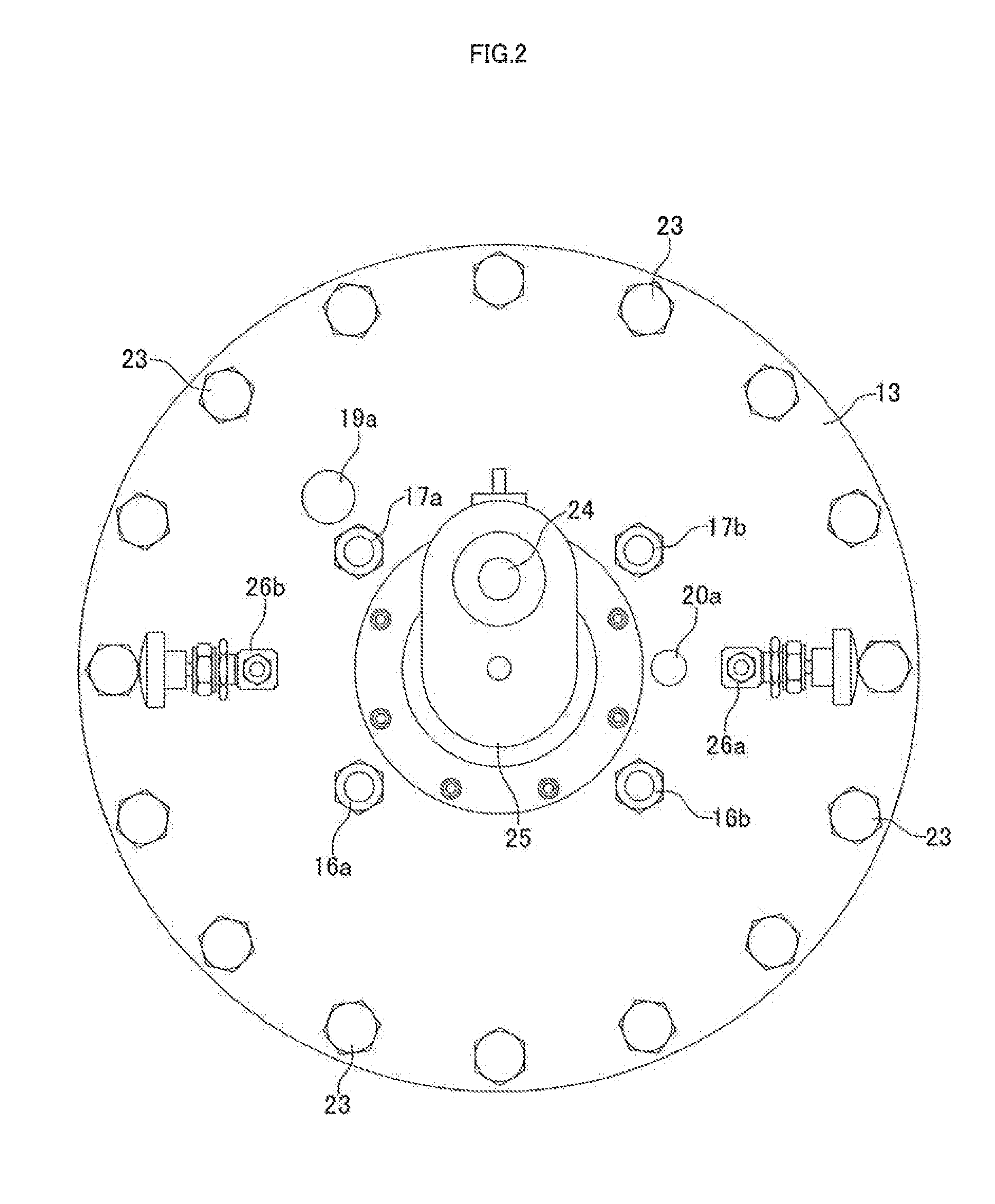

[0022]A heat exchanger 11 according to the embodiment comprises: a vacuum insulated double walled vertically long bottomed cylindrical container 12 which is filled with brine, a disk-shaped lid 13 closing an upper portion opening of the container 12, a rotation axis 14 which penetrates the center of the lid 13 to be arranged in the container 12 in the axis direction, a plurality of axial-flow propellers 15 provided on the rotation axis 14 in the vertical direction, a helical first hydrogen gas cooling tube 16 and a second hydrogen gas cooling tube 17 provided in a vertically two-stage structure around the rotation axis 14 and the propeller 15, and a plurality of cooling medium tubes 18 for cooling brine which are arranged around the first hydrogen gas cooling tube 16 and the second hydrogen gas cooling tube 17 in the axis direction.

[0023]The upper end and the lower end of each of the plurality of cooling medium tubes 18 for cooling brine are communicatively connected to an annular u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com