Small Form-Factor Pluggable Optical Transceiver

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

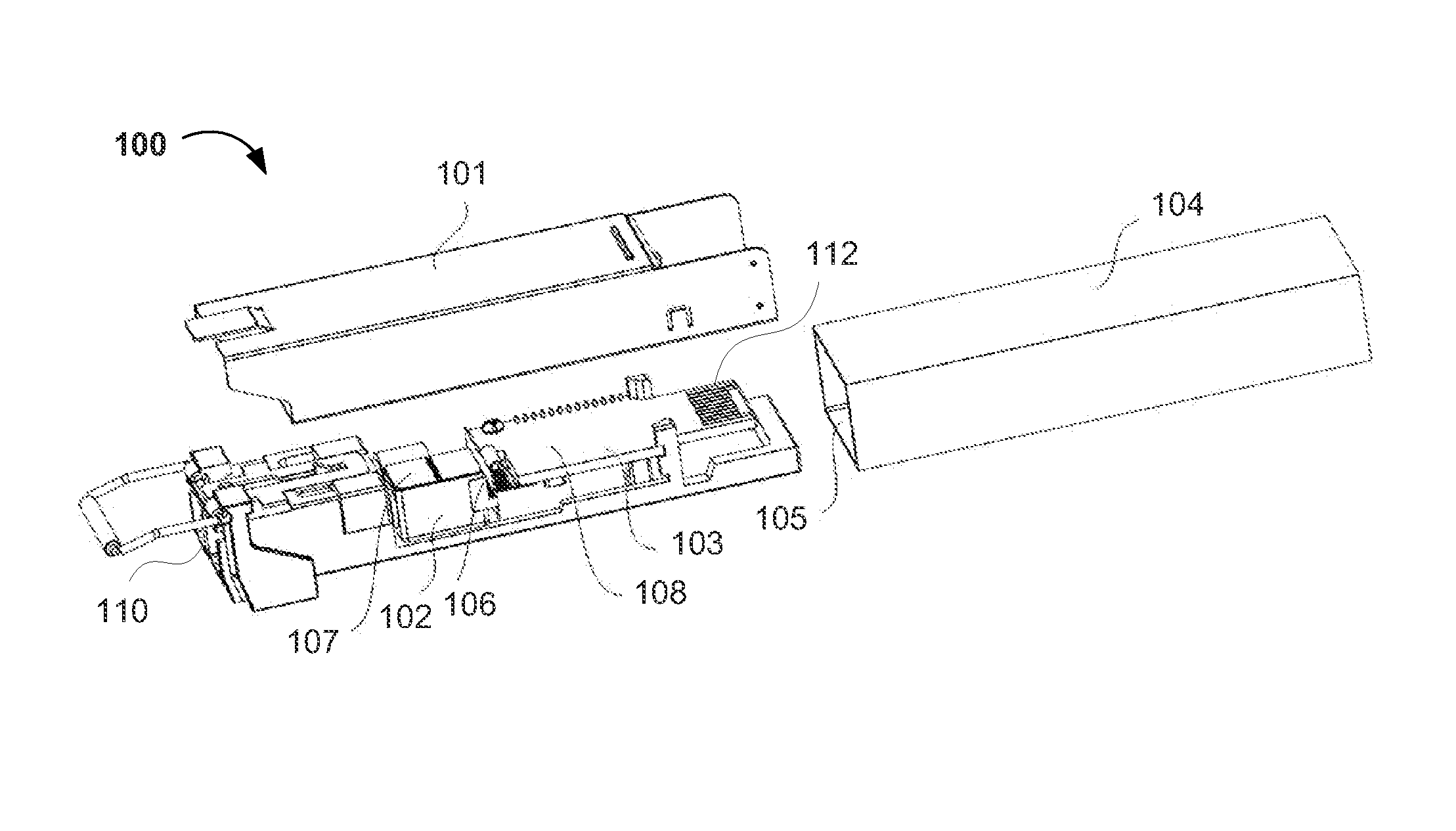

[0028]As shown in FIG. 1, a small form-factor pluggable (SFP) optical transceiver 100 comprises a casing 101 having an optical port 110 and an electrical port 112. The casing 101 is configured to accommodate optical devices 102 and electrical devices 103. The optical device 102 comprises a transceiver optical subassembly (TOSA) and a receiver optical subassembly (ROSA). The electrical devices 103 are located on a printed circuit board (PCB) on or near the bottom of the casing 101.

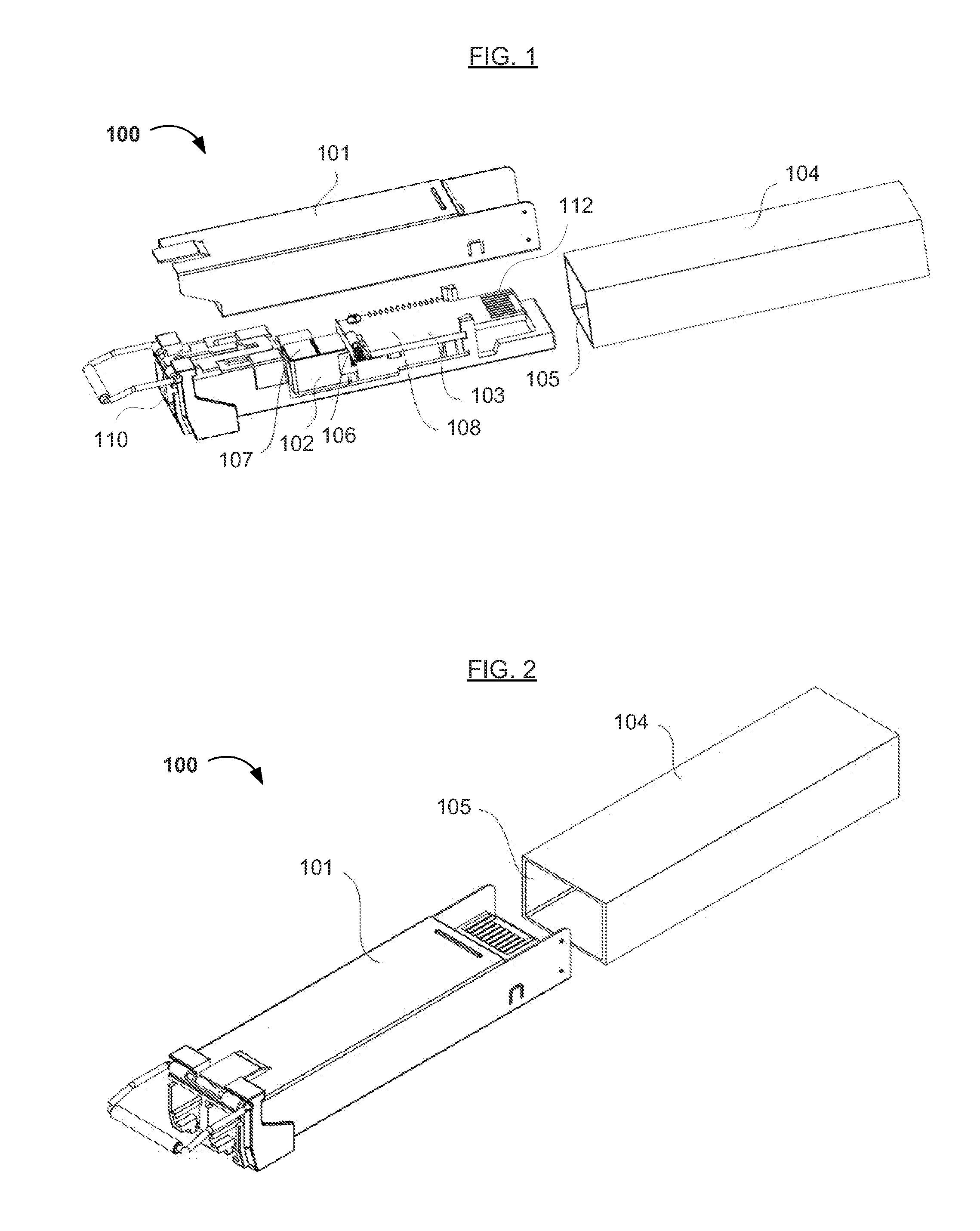

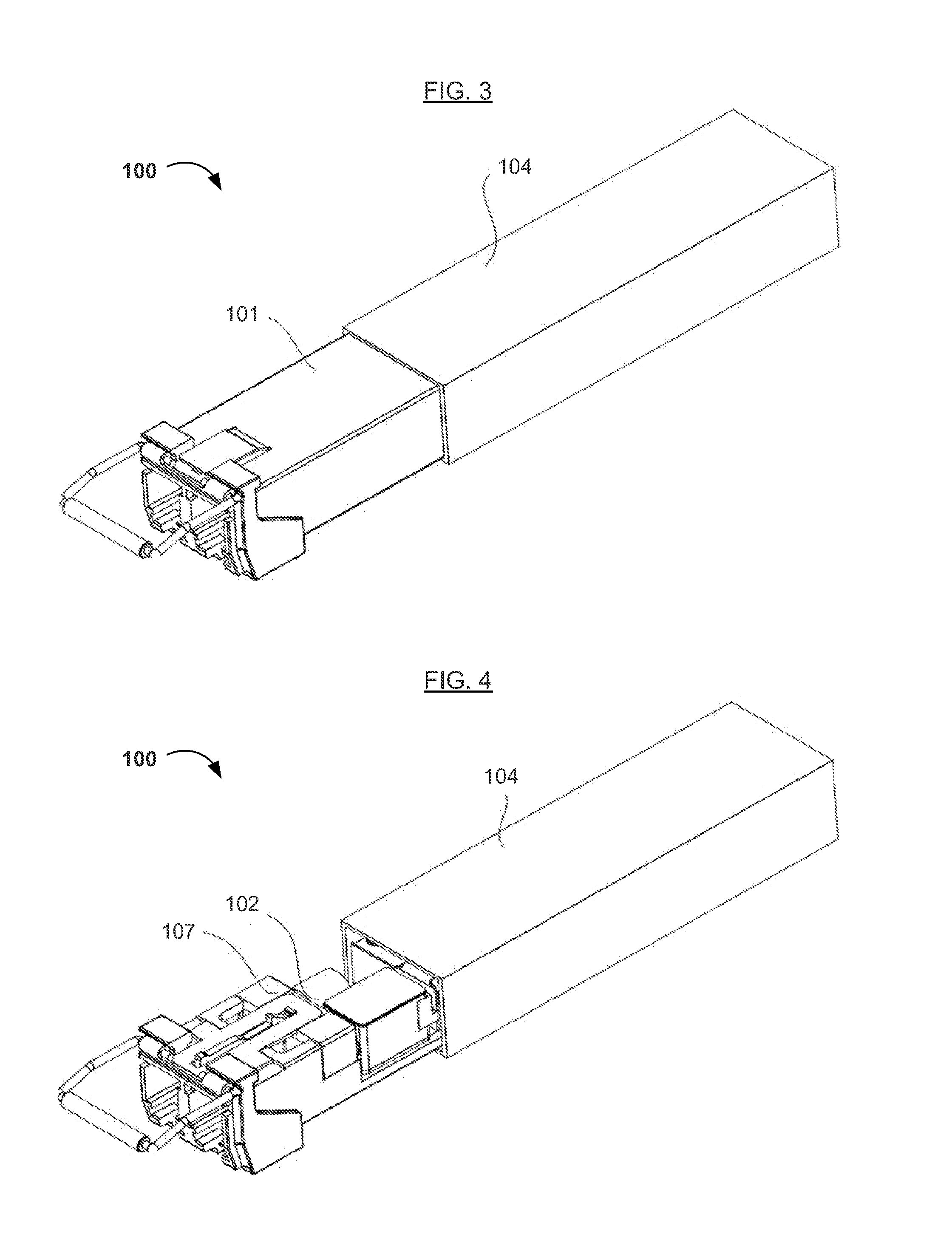

[0029]As shown in FIGS. 2-4, during normal operation, the casing 101 is connected to a switchboard 104 via a connector 105 located in the switchboard 104. As shown more clearly in FIG. 3, one portion of the casing 101 stays outside of the switchboard 104 after the casing 101 is inserted into the connector 105 located in the switchboard 104. More specifically, the electrical devices 103 inside the casing 101 and the portion of the casing 101 enclosing the electrical devices 103 stay inside the switchboard 10...

embodiment 2

[0031]As shown in FIGS. 5 and 6, based on or from Embodiment 1 above, an SFP optical transceiver 200 (or a casing 201 therefor) has a built-in (e.g., internal) isolator 206. The isolator 206 is configured to divide the transceiver 200 (or casing 201) into a first cavity 207 close to or facing the optical port 210 and a second cavity 208 close to or facing the electrical port 212. The optical devices (not shown) are located in the first cavity 207, and the electrical devices (not shown) are located in the second cavity 208. After the transceiver 200 (or casing 201) is divided into two relatively independent cavities via the isolator 206, the portion 208 containing the electrical devices having a relatively high temperature is isolated from the portion 207 containing the optical devices. Heat produced by the electrical device portion 203 having a high temperature during normal operation can be blocked from being transferred to the cavity 207 where the optical devices are located, resu...

embodiment 4

[0038]The casing 201 of Embodiment 4, as shown in FIG. 6 for an SFP optical transceiver 200 is similar to other various casings.

[0039]Referring to FIG. 6, the casing 201 of FIG. 6 has a de-latching unit 215 on a top surface (e.g., face), in which the de-latching unit 215 is configured to latch the casing 201 (of FIG. 6) and the switchboard 204. Alternatively, the de-latching unit 215 releases the casing 201 (of FIG. 6) from the switchboard 204. In Embodiment 4, the de-latching unit 215 is located over or on top of the second cavity 208. When the second cavity 208 is inserted into the switchboard 204 and the first cavity 207 remains outside the switchboard, the casing 201 and the switchboard 204 are steadily connected.

[0040]In addition to keeping the first cavity 207 outside the switchboard 204, air holes 209 are located in the cover and base of the casing 201 (of FIG. 6) corresponding to the first cavity 207 to further increase heat dissipation efficiency. The air holes 209 run thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com