Stripping agent and method of use

a technology of stripping agent and stripping agent, which is applied in the direction of solvent extraction, separation process, dissolving, etc., can solve the problems of reducing the space available for adsorption of the favored precious metal, requiring additional and expensive processing steps, and not without its problems, so as to reduce mercury emissions in precious metal mining operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017]Unless otherwise explained, all technical and scientific terms used herein have the same meaning as commonly understood by one of ordinary skill in the art to which this disclosure belongs. In case of conflict, the present specification, including explanations of terms, will control. The singular terms “a,”“an,” and “the” include plural referents unless context clearly indicates otherwise. Similarly, the word “or” is intended to include “and” unless the context clearly indicates otherwise. The term “comprising” means “including;” hence, “comprising A or B” means including A or B, as well as A and B together.

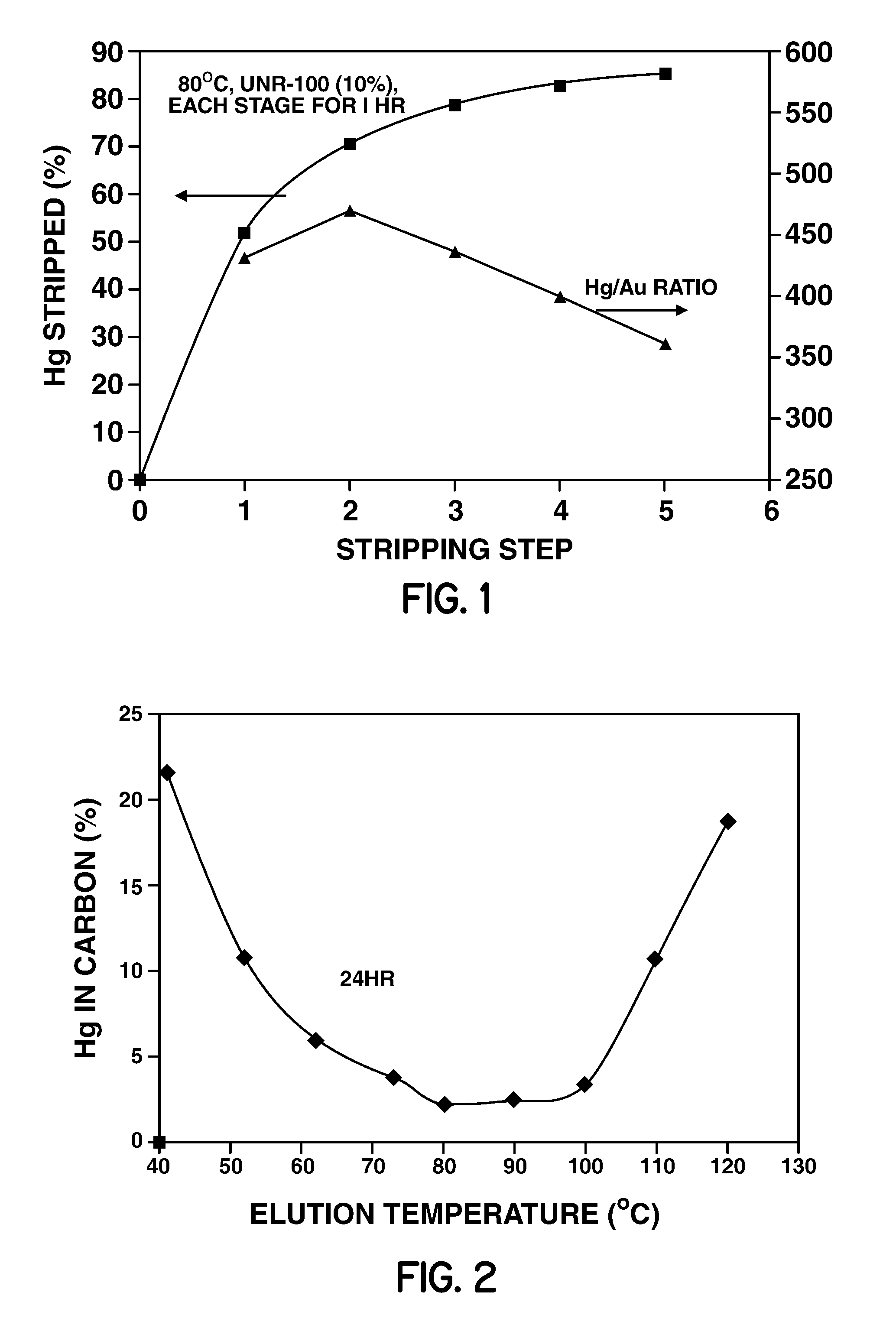

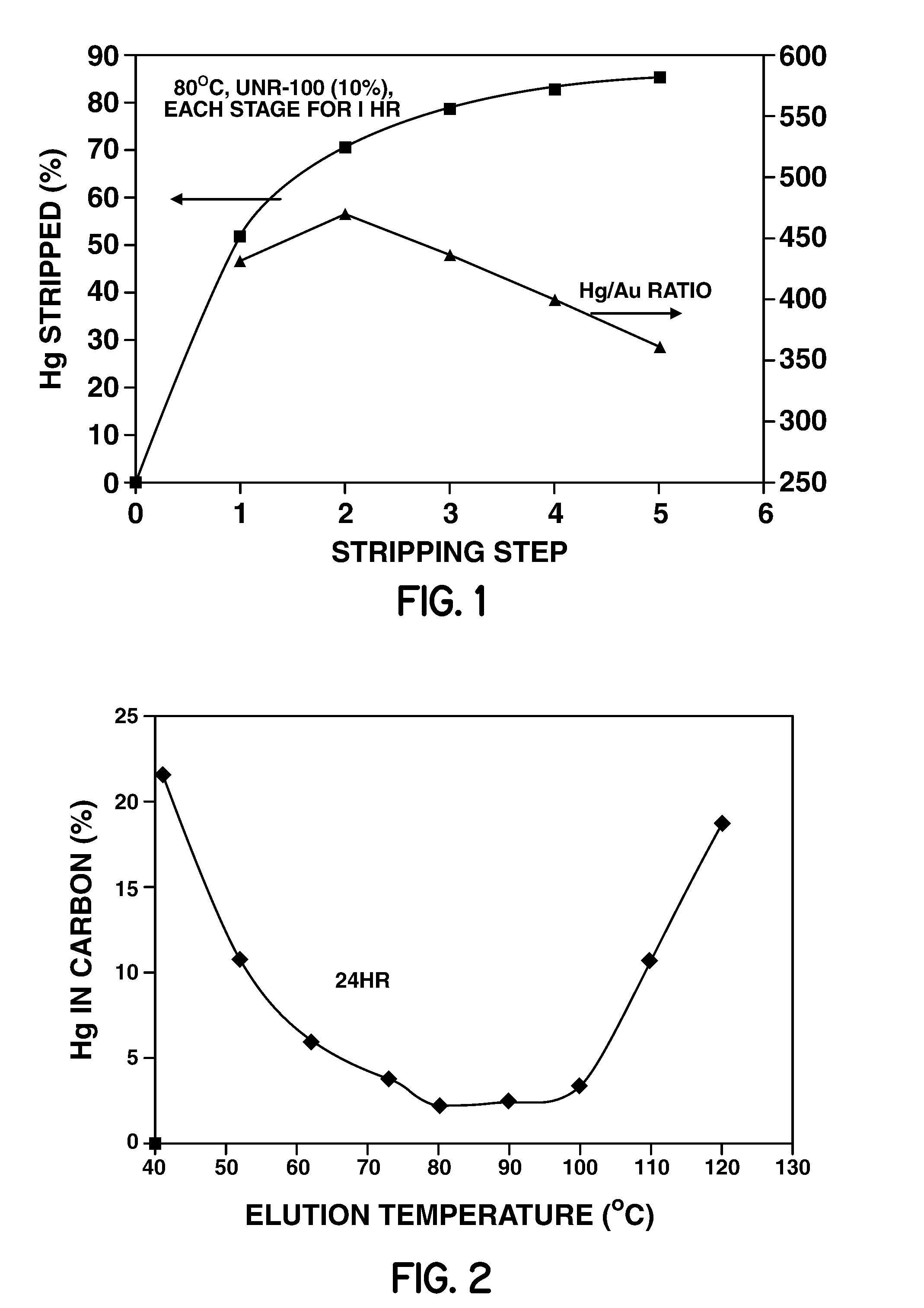

[0018]According to the present disclosure, methods of removing mercury from an activated carbon substrate are provided. The process also has the added benefit of eliminating calcium salts and other inorganic scalants that can accumulate on activated carbon used to recover precious metal cyanide complexes from leach solutions. These methods, which upon their application to p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com