Fixing device for fixing toner on sheet by heating toner, and image forming apparatus including fixing device

a technology of fixing device and fixing roller, which is applied in the direction of electrographic process apparatus, instruments, optics, etc., can solve the problems of uneven heat generation in the circumferential direction of the fixing film, small power consumption amount, and heavy rotation load on the fixing roller, so as to reduce the rotation load reduce the deformation of the rotatable heating element, and improve the effect of electric power transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

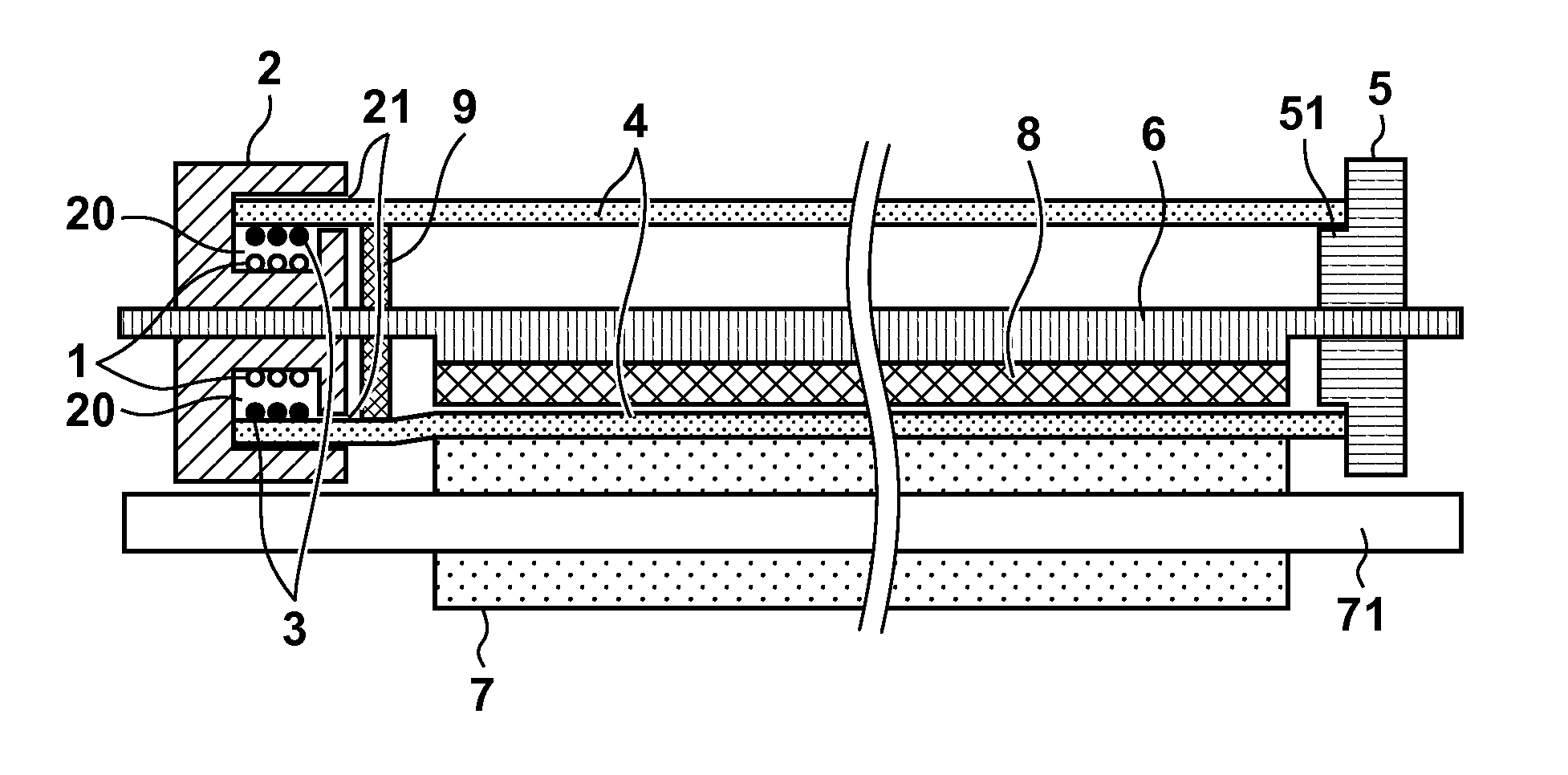

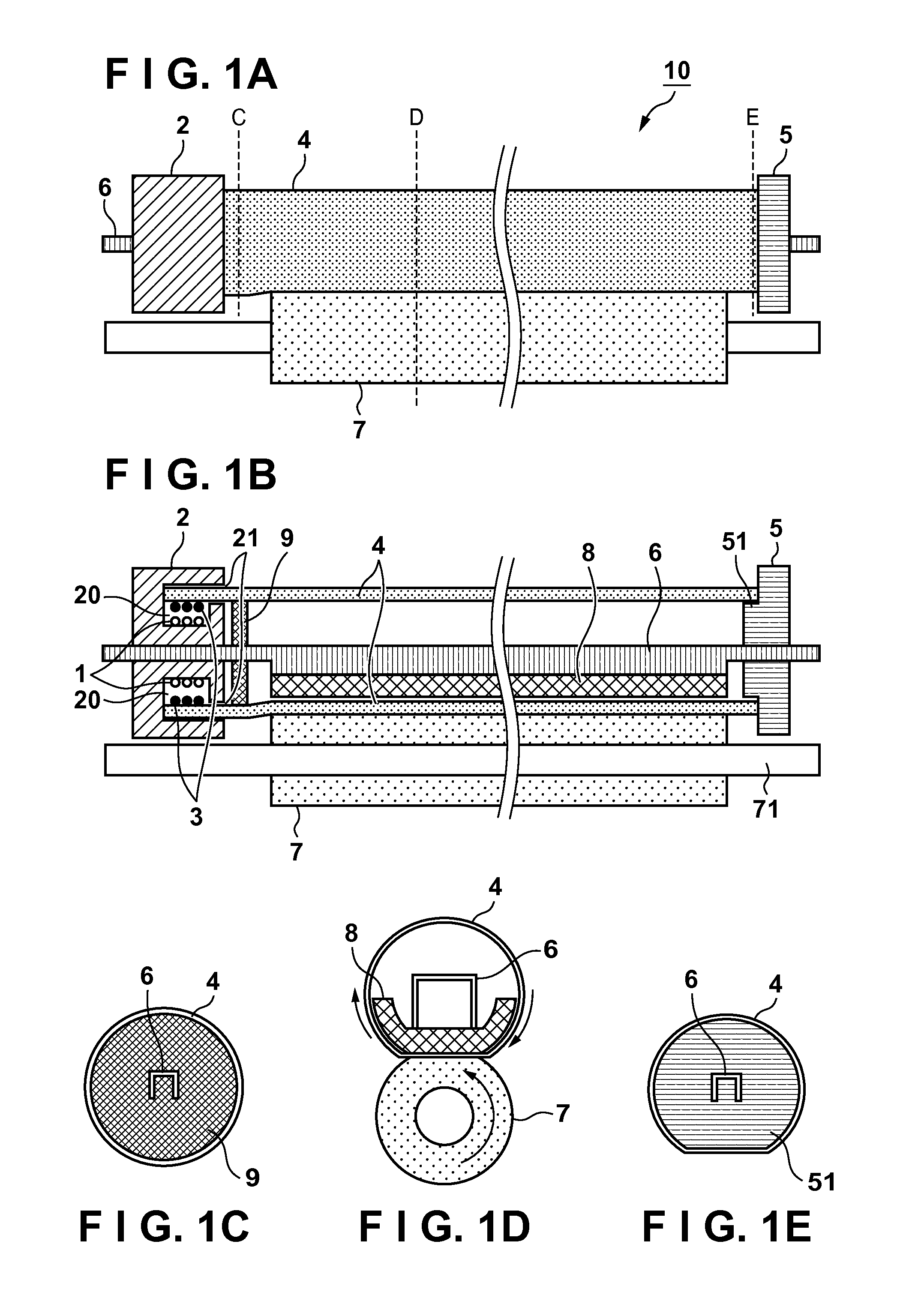

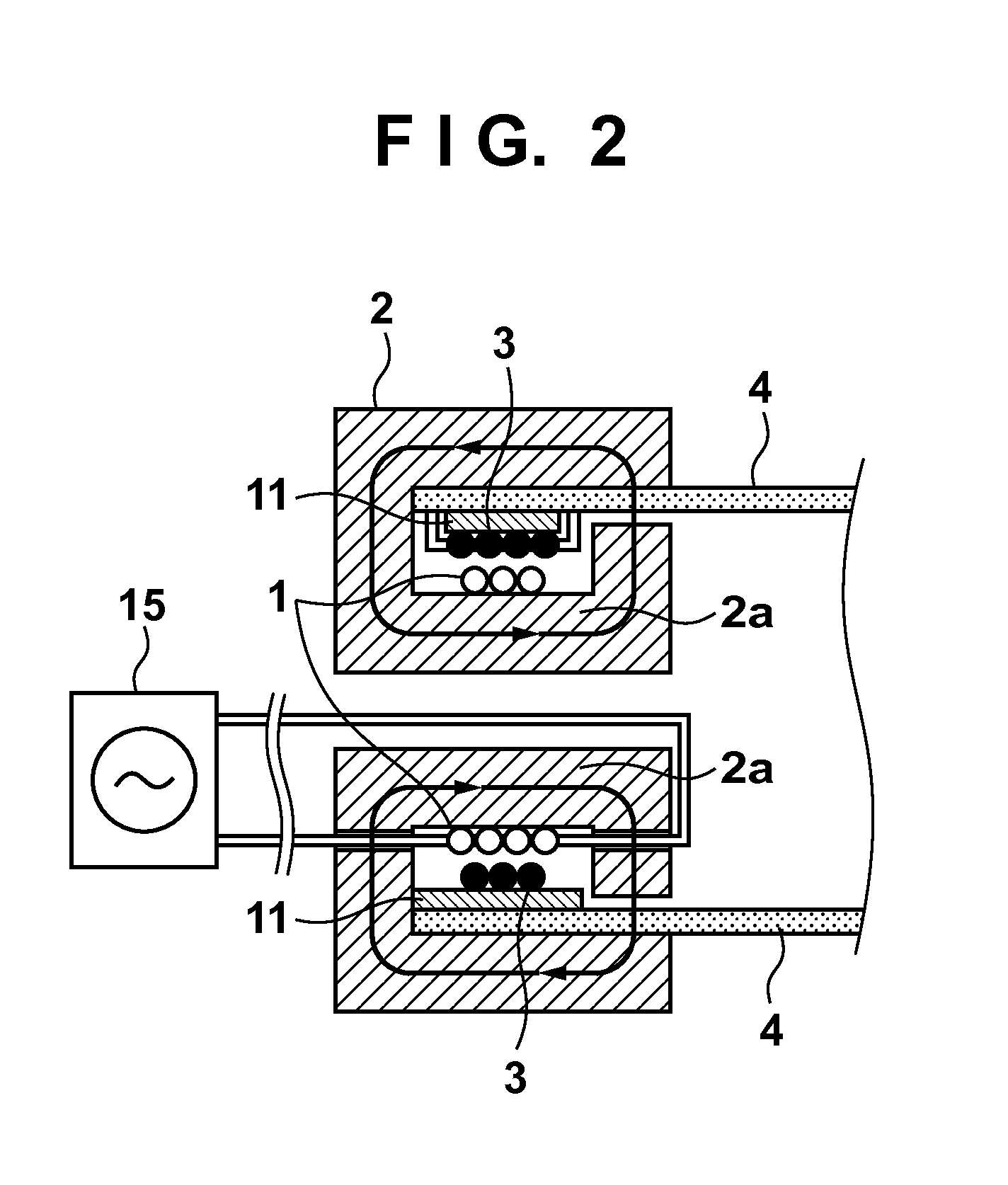

[0057]As described above, the secondary coil 3 is arranged in the end portion of the heating film 4, and the primary coil 1 and secondary coil 3 are arranged in the space 20 formed inside the core member 2. Since the core member 2 is designed to roughly surround the primary coil 1 and secondary coil 3, induction of a leaking magnetic flux can be suppressed to be low. Therefore, electric power can be efficiently transmitted from the primary coil 1 to the secondary coil 3. The core member 2 is fixedly arranged in the fixing device 10, and the rotating heating film 4 does not include the core member 2. For this reason, the rotation load on the heating film 4 can be reduced. That is, since the core member 2 does not impose any load on the heating film 4, the heating film 4 is nearly free from any deformation such as torsion.

[0058]The outer diameter of the primary coil 1 is smaller than the inner diameter of the secondary coil 3, and the primary coil 1 is arranged on the inner circumfer...

second embodiment

[0070]The shape of a core member 2 of the second embodiment will be described below with reference to FIGS. 9A, 9B, 9C, and 9D. FIG. 9A is a sectional view taken along a central axis direction (a direction parallel to a longitudinal direction of a heating film 4) of the core member 2. FIGS. 9B, 9C, and 9D are sectional views respectively taken along broken lines B, C, and D shown in FIG. 9A.

[0071]As shown in FIGS. 9B, 9C, and 9D, a sectional shape of each of a central portion 2a, left side surface 2b, outer circumferential surface 2c, and right side surface 2d of the core member 2 is circular in a portion and is flattened in the remaining portion.

[0072]That is, each of these sectional shape is quasi-circular (hog-backed or D shape). As described above, in order to form a fixing nip portion, a shape of a circumferential surface of a portion of the heating film 4 is flattened by shapes of a film guide 8 and fixing flange 5 during rotation. Thus, a sectional shape of a communicating po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com