Mobile on-wing engine washing and water reclamation system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

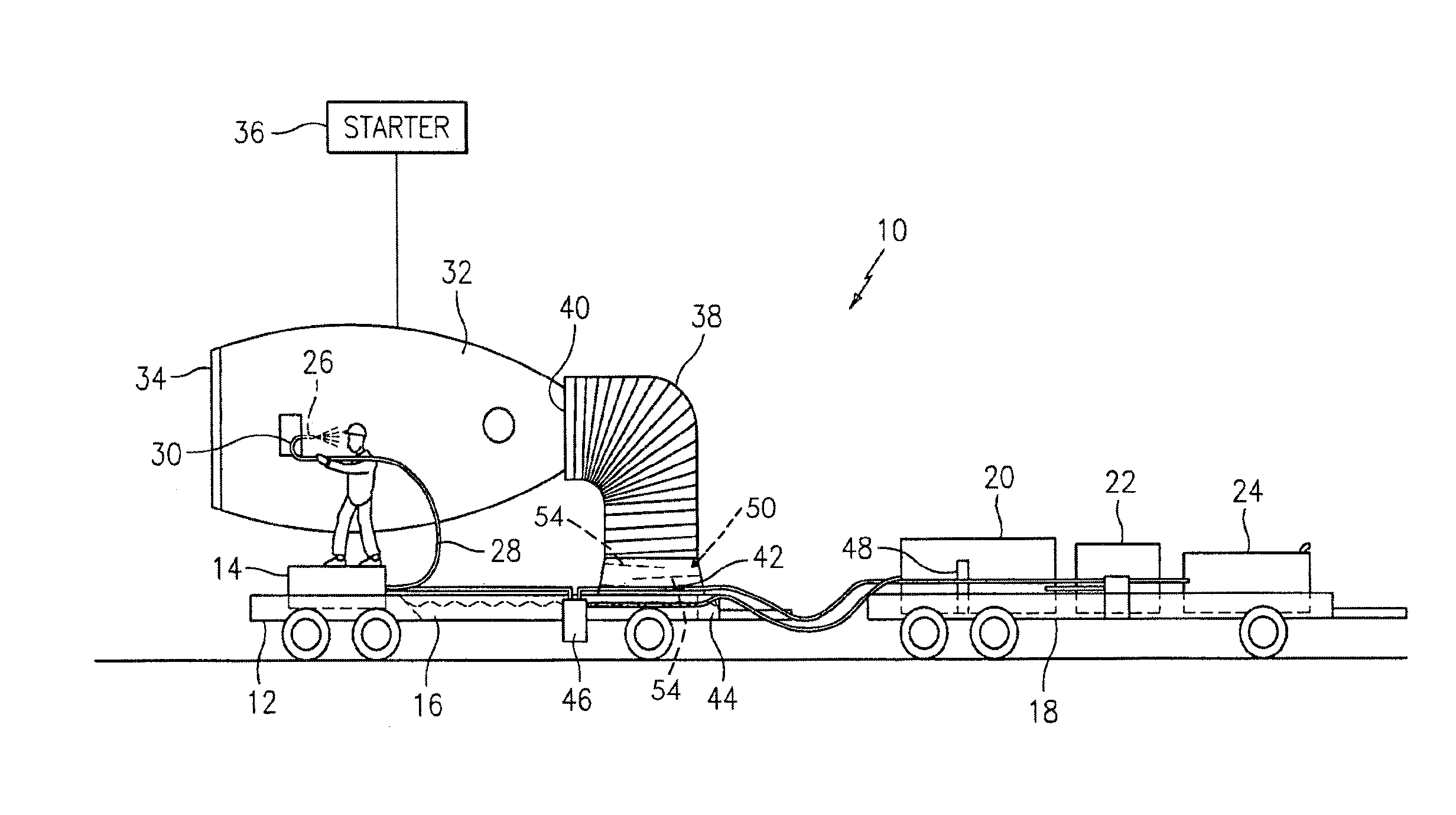

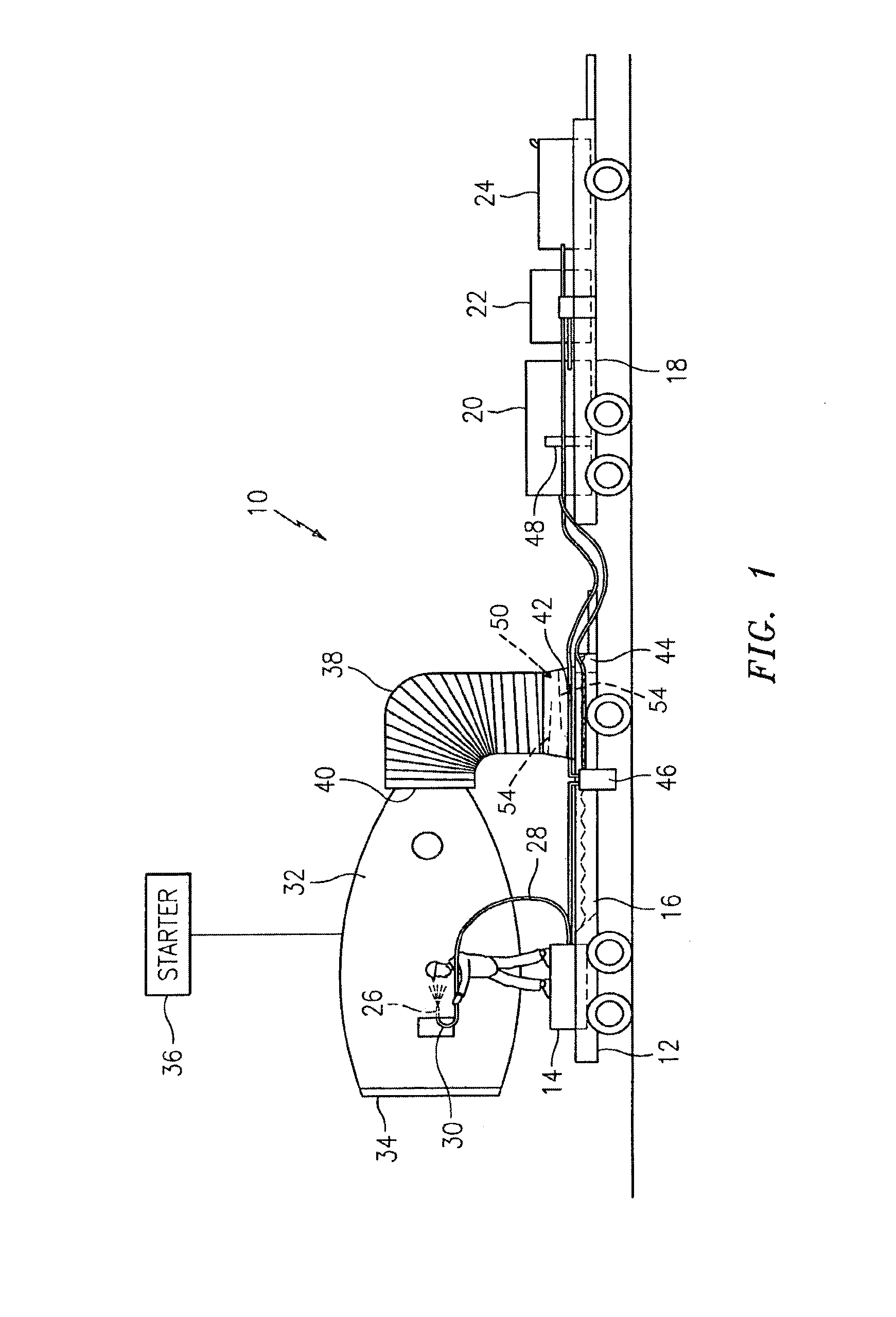

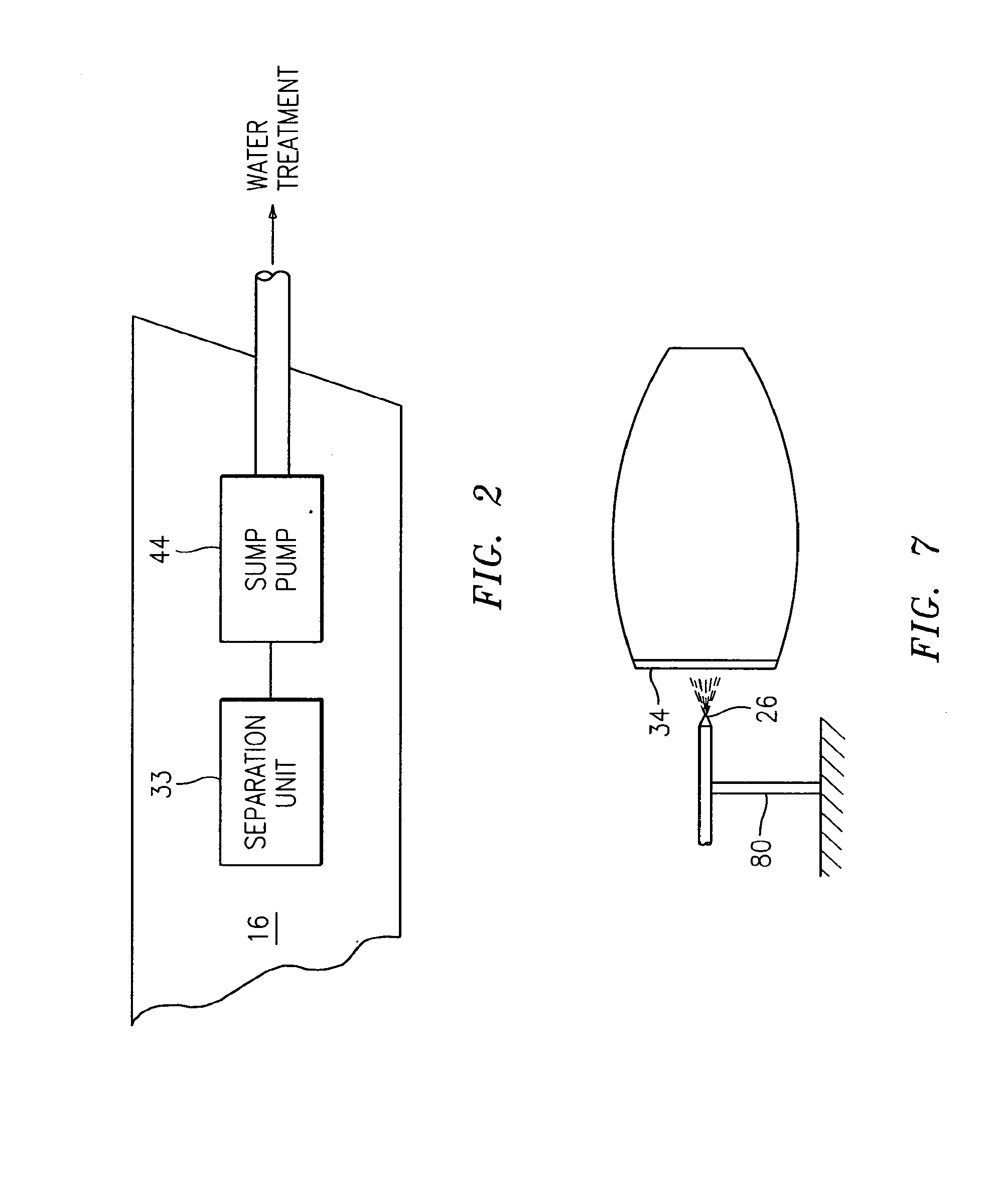

[0022]Referring now to FIGS. 1 and 2, there is shown a mobile on-wing engine washing and water reclamation system 10 in accordance with the present invention. The system 10 includes a mobile unit 12 on which there is located a source 14 of cleaning liquid and a used cleaning liquid collection trough or effluent trough 16. The system 10 also includes a second mobile unit 18 on which there is located a water treatment unit 20, a collection tank 22, and a generator 24 for mobile power production. While the trough 16 has been shown as being on mobile unit 12, it could be located on the second mobile unit 18 or on yet another mobile unit.

[0023]The cleaning liquid source 14 may contain water by itself or water mixed with an appropriate detergent. The detergent may comprise any suitable detergent known in the art in any suitable concentration. The particular type of detergent used, if any, depends on the type of contaminants, dirt, etc. to be removed. The cleaning liquid source 14 may com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| aerodynamic performance | aaaaa | aaaaa |

| exhaust gas temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com