Bi-Directional Overrunning Clutch With Improved Indexing Mechanism

a bi-directional overrunning and indexing technology, applied in the field of clutches, can solve the problems of cumbersome vehicles, vehicle stopping, and more expensive limited slip differentials, and achieve the effects of improving the indexing mechanism, and improving the indexing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

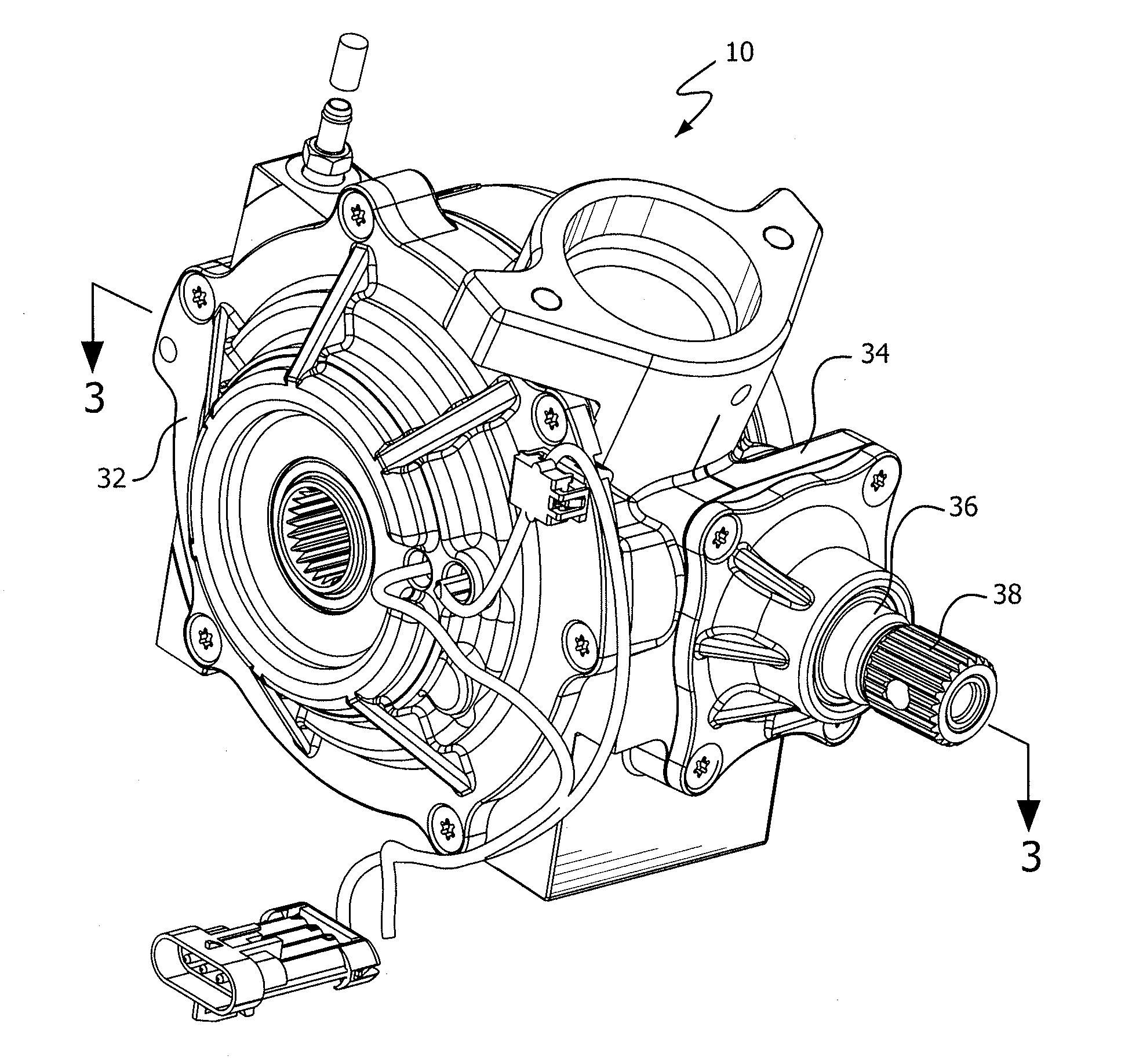

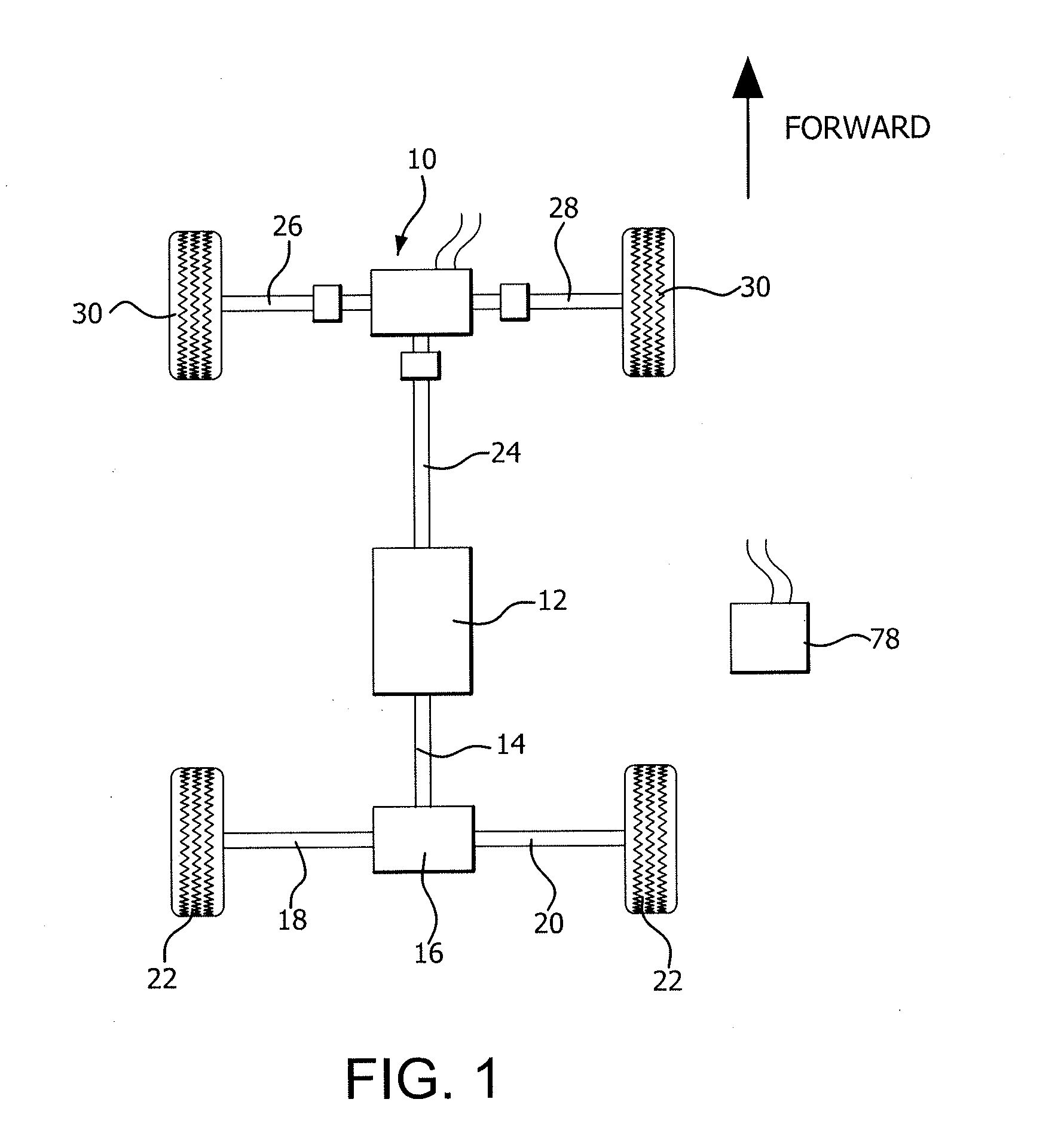

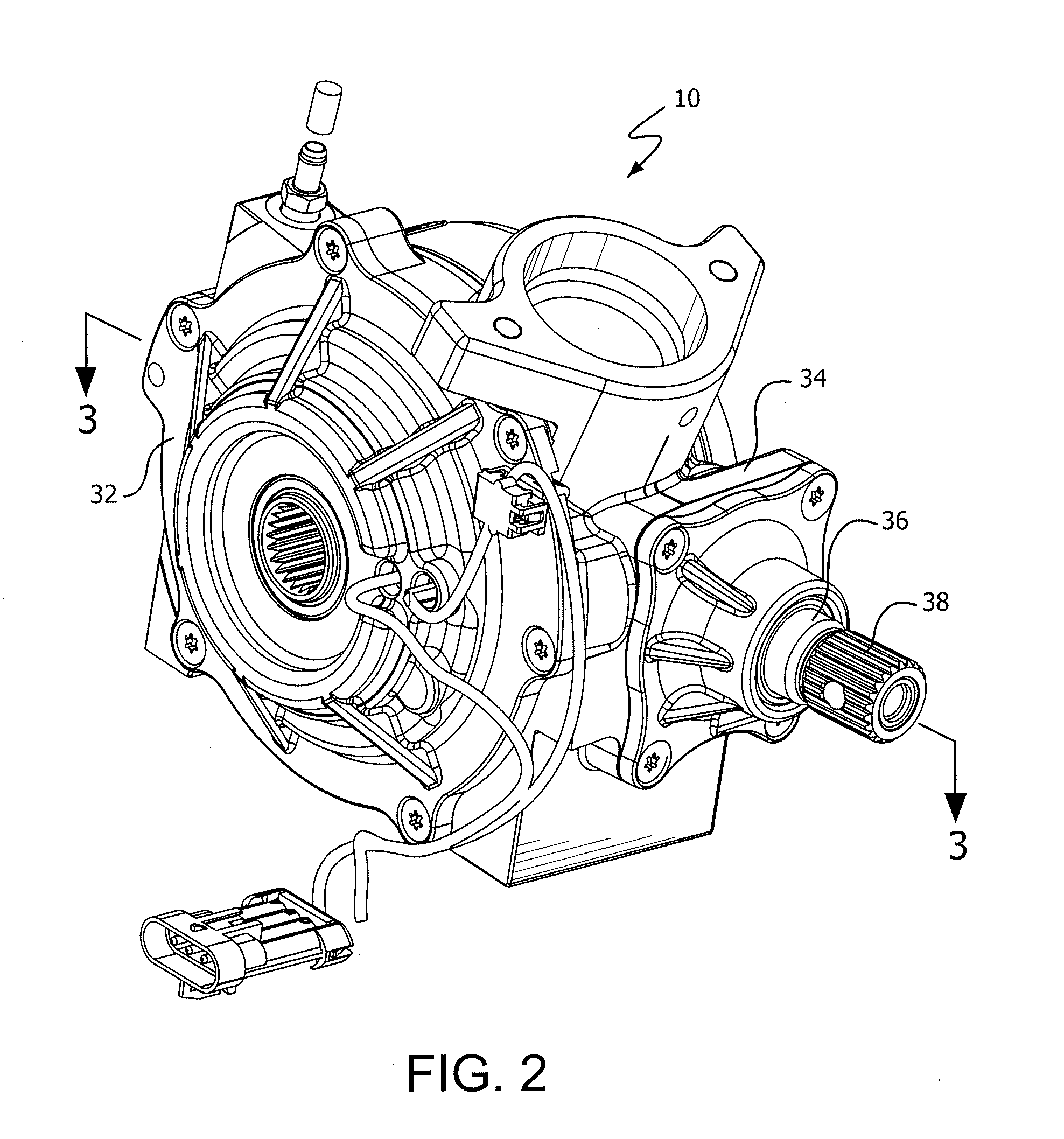

[0040]Referring now to the drawings, wherein like reference numerals illustrate corresponding or similar elements throughout the several views, FIG. 1 is a schematic representation of one embodiment of a drive system incorporating a bi-directional overrunning clutch assembly 10 according to an embodiment of the present invention. The drive system includes a transmission 12, a primary drive shaft 14 a primary differential 16, and first and second primary driven shafts 18, 20 which drive primary wheels 22.

[0041]The drive system also includes a secondary drive shaft 24 which is rotatably connected to the bi-directional overrunning clutch assembly 10 through any conventional means known to those skilled in the art, such as a splined connection. The bi-directional overrunning clutch assembly 10, in turn, rotatably drives two secondary driven shafts 26, 28 which are attached to wheels 30.

[0042]The details of the bi-directional overrunning clutch assembly will now be described with respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com