Profiled frame element

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

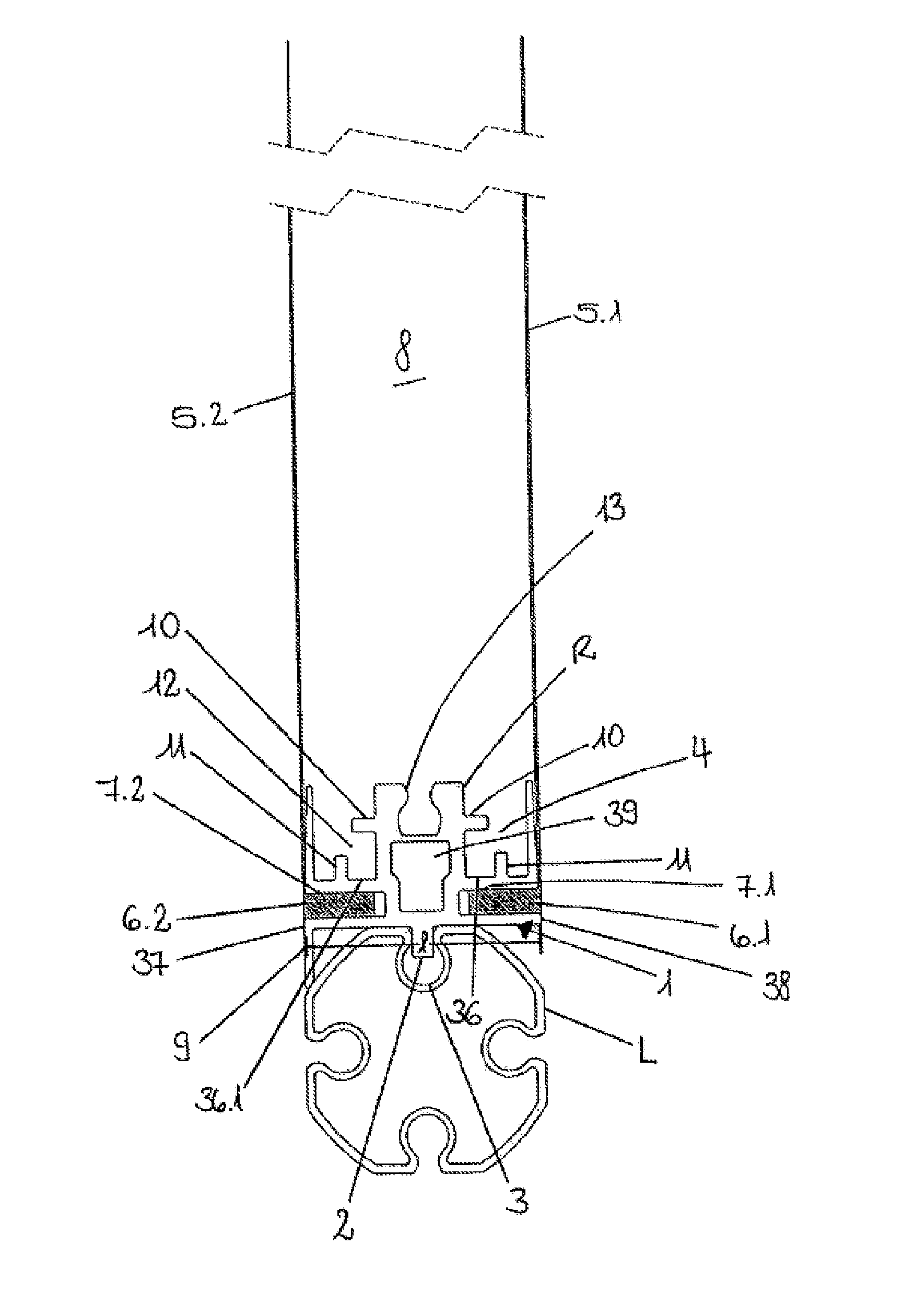

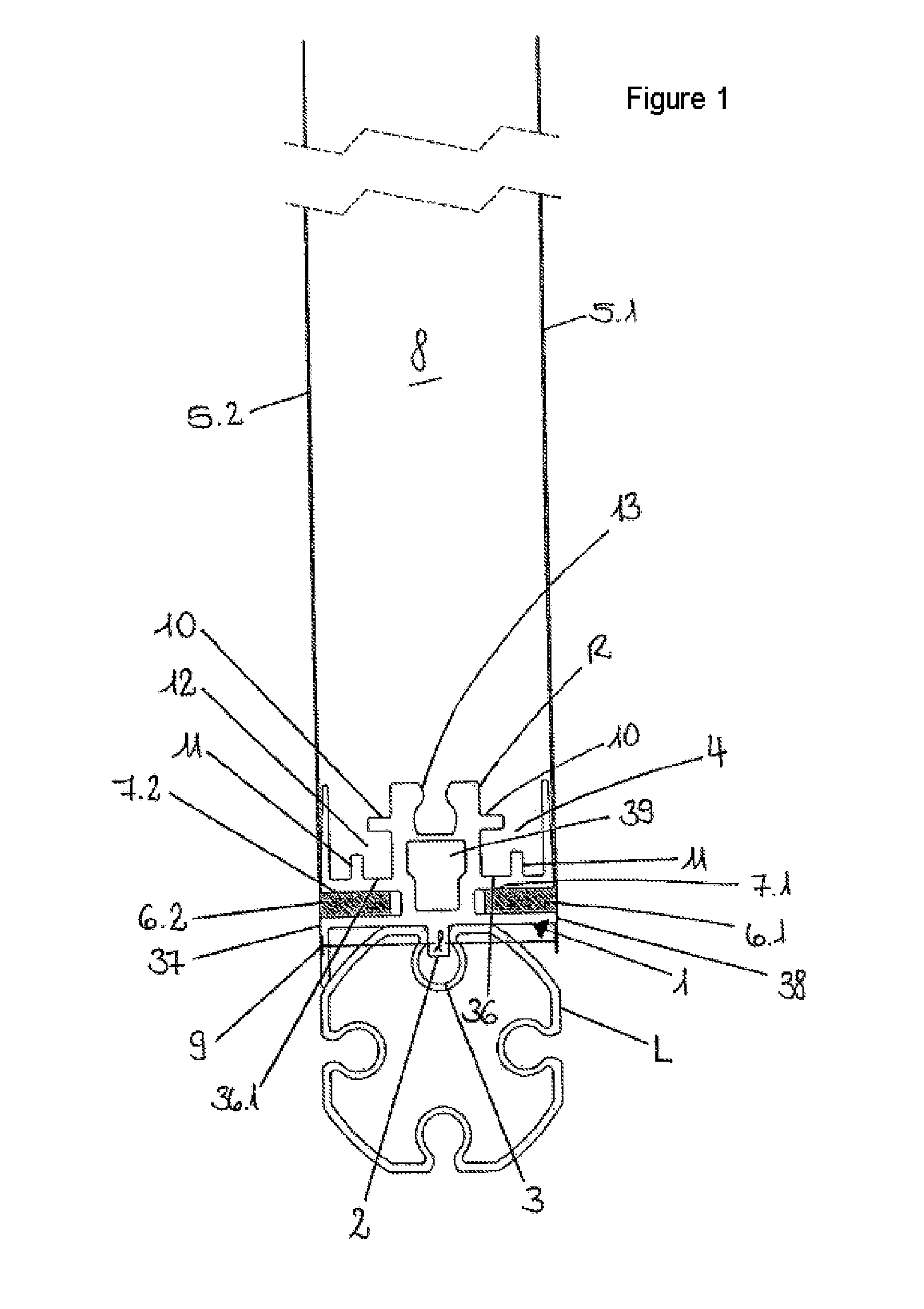

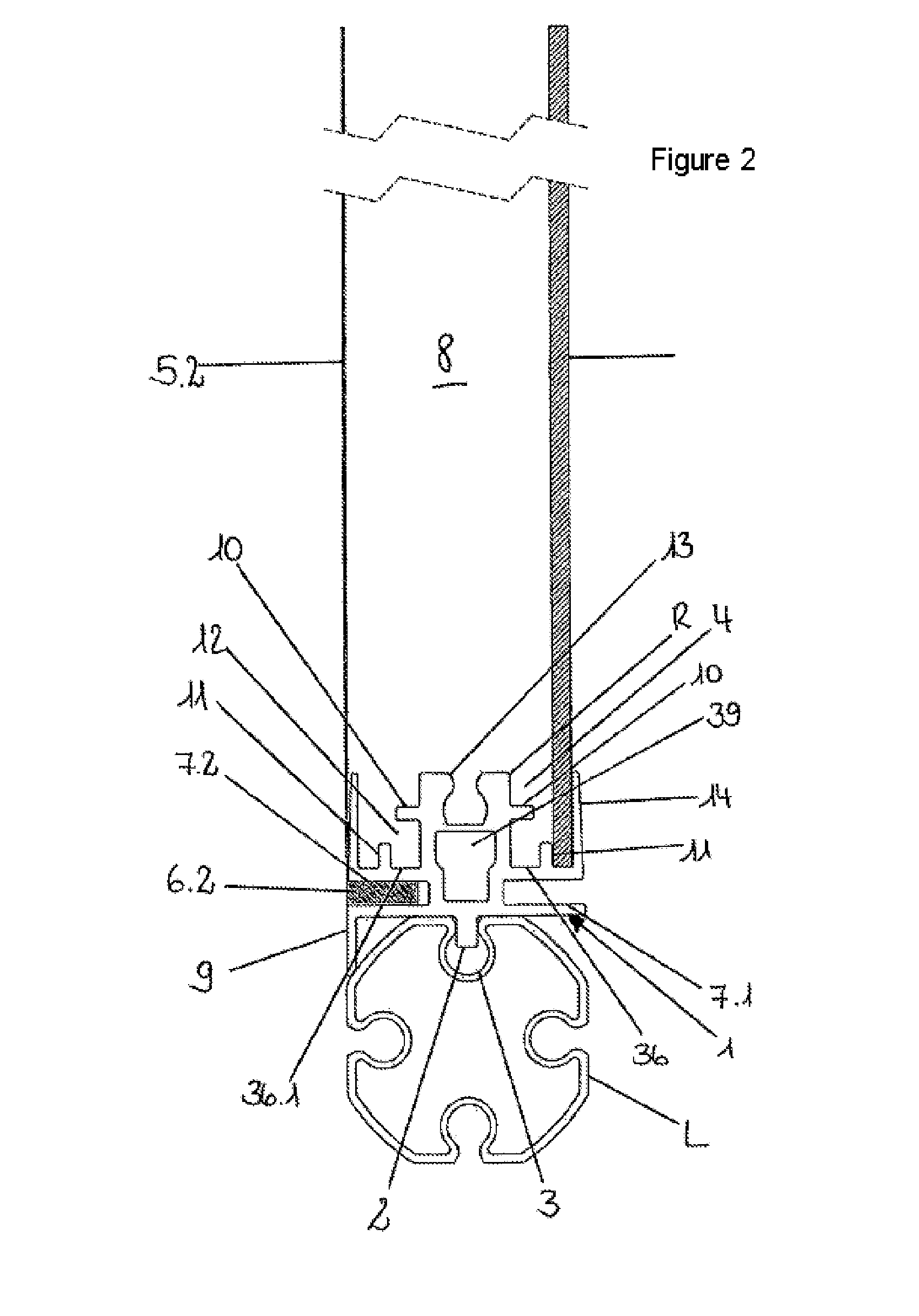

[0043]FIG. 1 shows an exemplary embodiment of a frame profile R according to the invention. Said frame profile R serves for attachment to a longitudinal profile L. For this purpose, a main member 1 is provided. On said main member 1 there is formed a guide lug 2. In FIG. 1, the guide lug 2 projects into a groove 3 of the longitudinal profile L. Furthermore, the frame profile R has a slot 4 for different wall thicknesses of solid wall fillings. It can also be seen how in each case one textile wall 5.1, 5.2 can be connected to the frame profile R by insertion of a flat welt 6.1 and 6.2 into a groove 7.1 and 7.2. The flat welt 6.1, 6.2 forms a unit with the textile wall 5.1, 5.2. The intermediate space 8 between the textile walls 5.1, 5.2 can be used for accommodating various insulation elements. The intermediate space 8 may however also be implemented without the use of insulation elements. FIG. 1 also shows how a faceplate 9 is formed on the main member 1. Said faceplate 9 is formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com