Systems and Methods for Electric and Heat Generation from Biomass

a technology of electric and heat generation and biomass, which is applied in the direction of combustion types, lighting and heating apparatuses, machines/engines, etc., can solve the problems of significant difficulties in using biomass over fossil fuels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

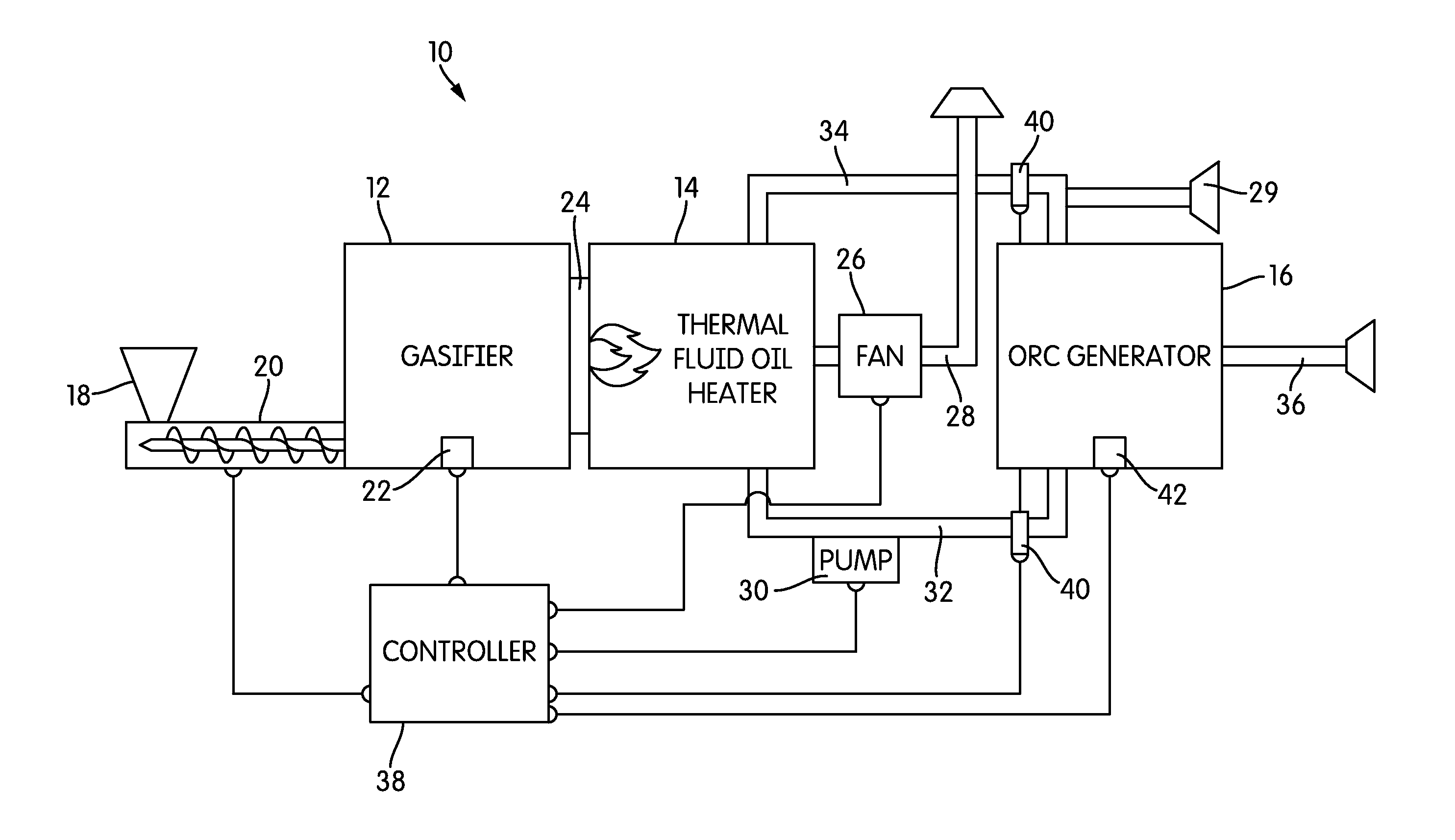

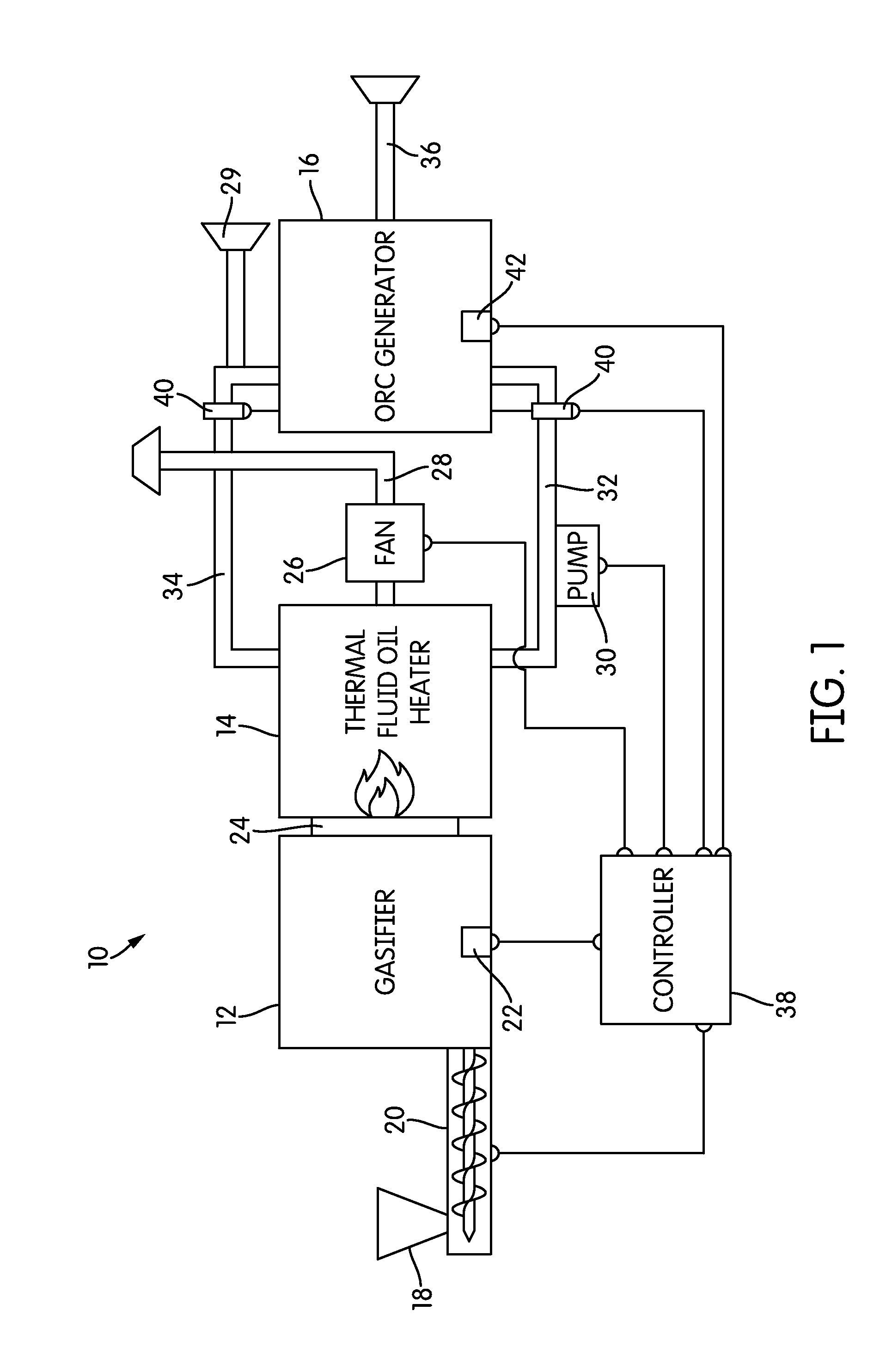

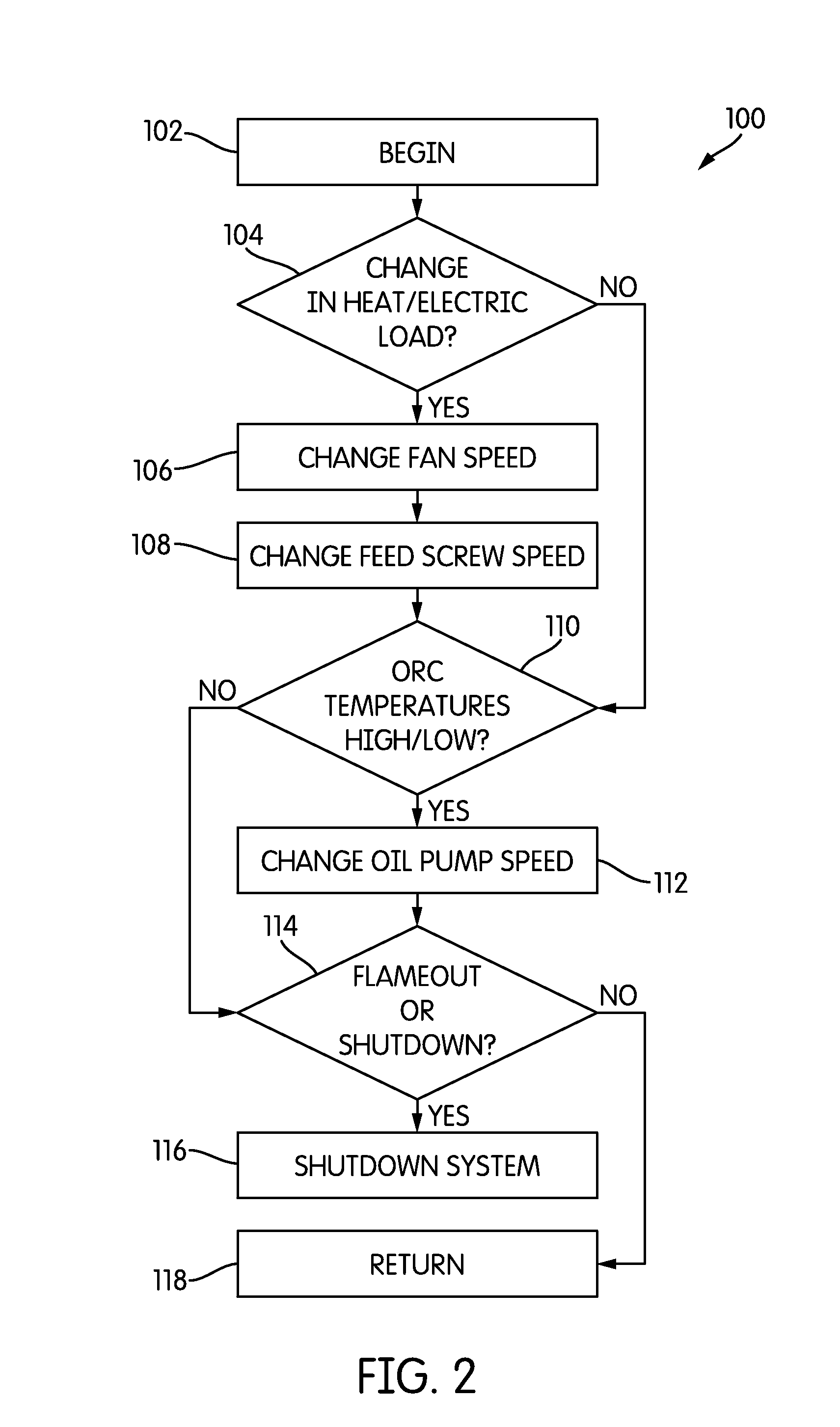

[0014]FIG. 1 is a schematic illustration of a system for producing power, generally indicated at 10, according to an embodiment of the invention. System 10 is particularly adapted to use biomass as a primary fuel, and combines three technologies to produce power: a gasifier 12, a thermal fluid oil heater 14, and a generator that uses the organic Rankine cycle 16.

[0015]The process of producing power begins when a user adds biomass to a feed hopper 18. As used here, the term “biomass” refers to any plant-based material that may be used as a fuel. The biomass fuel drops or is fed into a feed screw 20 which is driven by a variable and controllable speed motor (not shown in FIG. 1). As the feed screw 20 turns, the biomass fuel is fed into the gasifier 12 at a defined rate. As will be described below in more detail, the feed rate may be increased or decreased as necessary.

[0016]The gasifier 12 of the illustrated embodiment is a cross-draft gasifier, although essentially any type of gasifi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap