Manufacturing method of insole and insole manufactured by the method

a manufacturing method and technology of insoles, applied in the direction of uppers, insoles, bootlegs, etc., can solve the problems of insufficient function of insoles, inability to bear long-term use, increase manufacturing costs, etc., and achieve the effect of short time, reduced manufacturing time of insoles, and low cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017]Hereinafter, embodiments of the present invention are explained as referring to drawings.

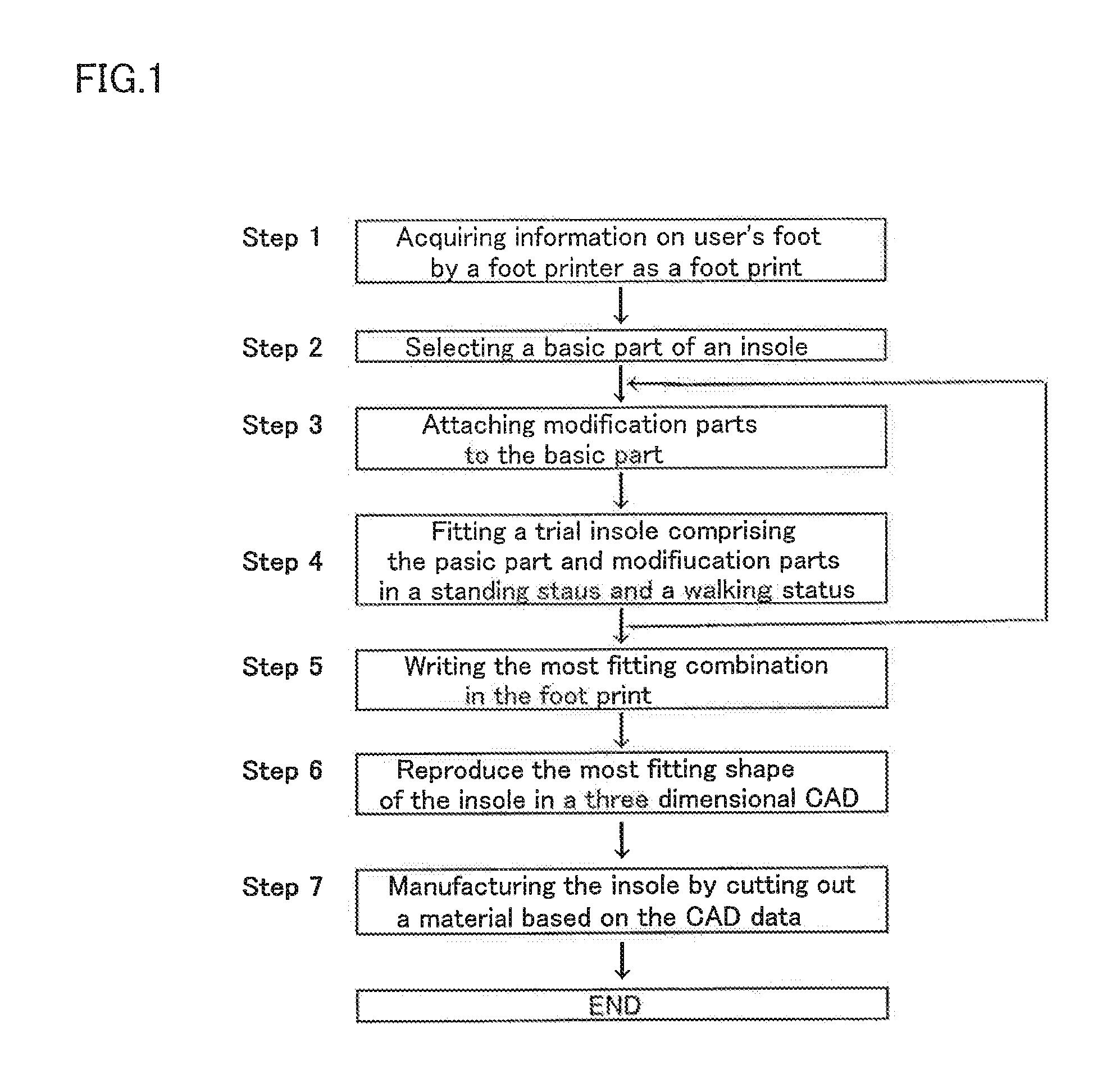

[0018]The manufacturing method of the insole by the present invention comprises a plurality of steps which are carried out in series. In step 1, information on a user's foot is acquired as a foot print by putting the foot on a foot printer. The information comprises a pressure pattern of a sole and a contour of the foot in a standing status acquired by the foot printer, and other information acquired by touching and observing the foot.

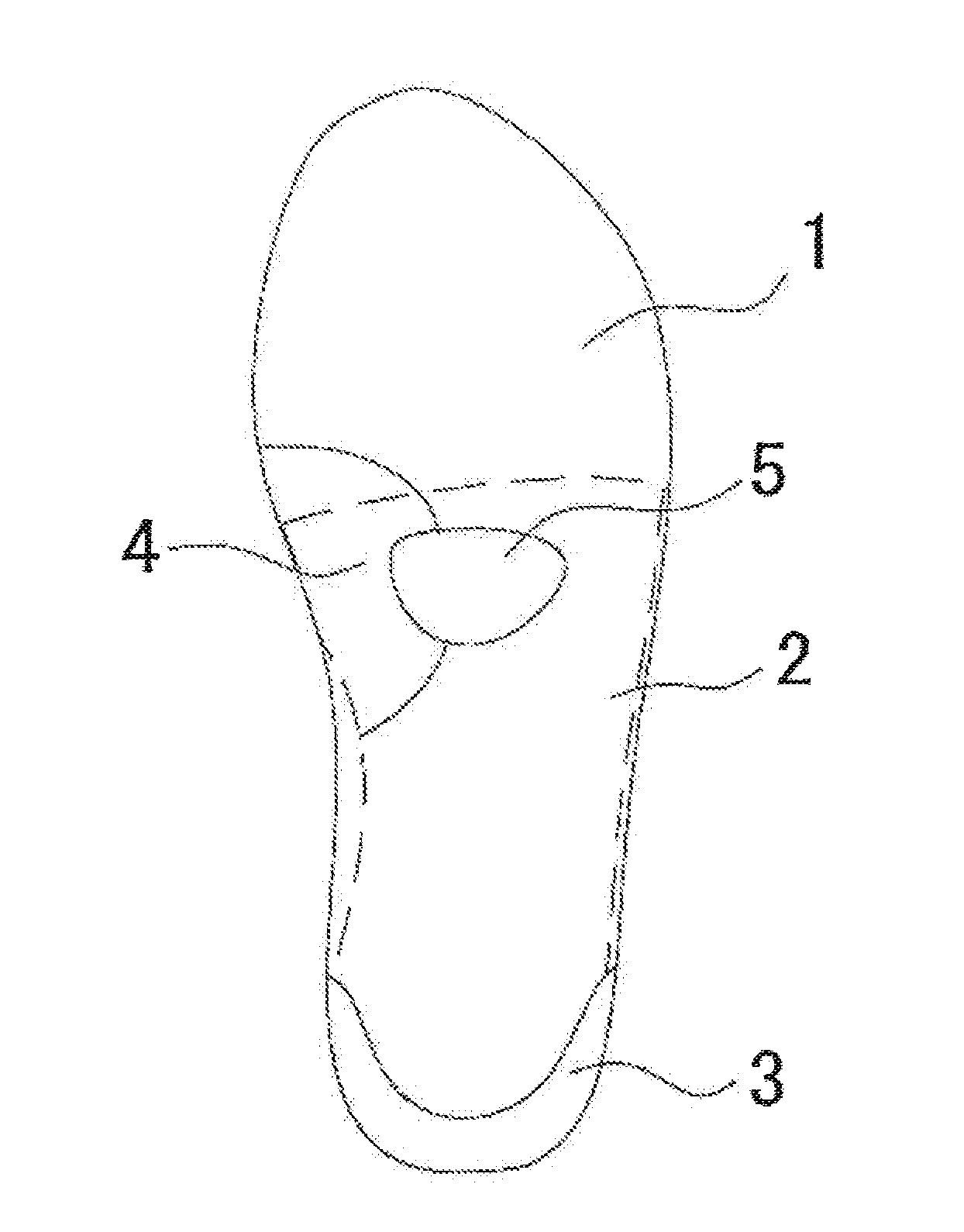

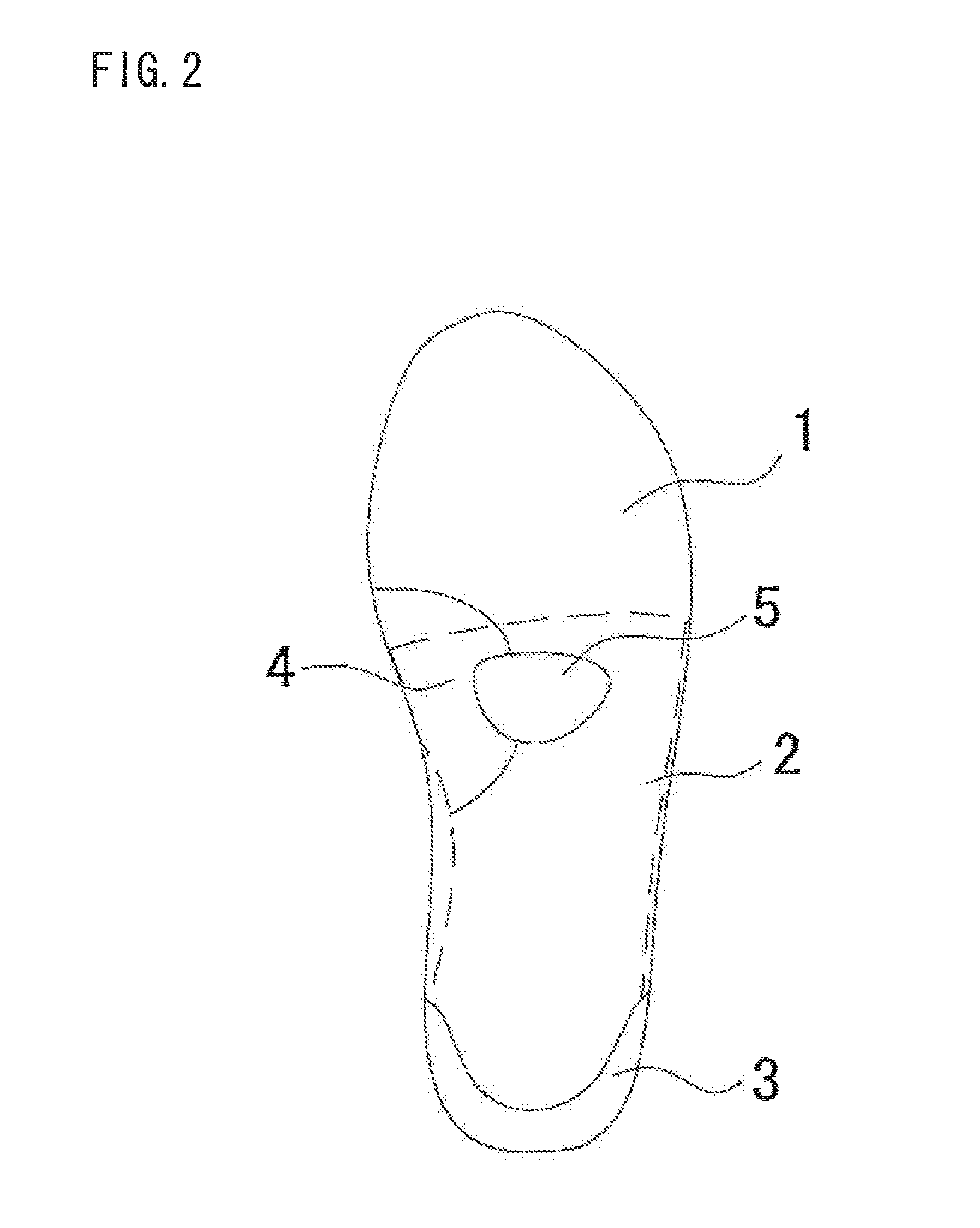

[0019]In step 2, based on the information acquired in step 1, a basic part 2 is selected among a group of basic parts with various patterns. The basic parts having different patterns are prepared beforehand. A basic part most fitting to the shape of the foot is selected among the group as the basic part 2. Data on the basic parts are registered in the three-dimensional CAD beforehand.

[0020]In step 3, a trial insole is formed by attaching modification parts 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com